Nissan Juke Service and Repair Manual : U0141 lost communication (BCM A)

Description

CAN (Controller Area Network) is a serial communication line for real-time application. It is an on-vehicle multiplex communication line with high data communication speed and excellent malfunction detection ability.

Many electronic control units are equipped onto a vehicle, and each control unit shares information and links with other control units during operation (not independently). In CAN communication, control units are connected with 2 communication lines (CAN-H line, CAN-L line) allowing a high rate of information transmission with less wiring. Each control unit transmits/receives data but selectively reads required data only

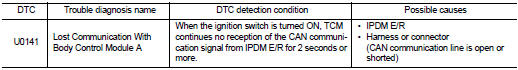

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PREPARATION BEFORE WORK

If another “DTC CONFIRMATION PROCEDURE” occurs just before, turn ignition switch OFF and wait for at least 10 seconds, then perform the next test.

>> GO TO 2.

2.PERFORM DTC CONFIRMATION PROCEDURE

With CONSULT-III

With CONSULT-III

1. Start the engine and wait for at least 5 seconds.

2. Check the DTC.

Is “U0141” detected? YES >> Go to TM-384, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

For the diagnosis procedure, refer to LAN-17, "Trouble Diagnosis Flow Chart".

U0140 lost communication (BCM)

U0140 lost communication (BCM)

Description

CAN (Controller Area Network) is a serial communication line for real-time

application. It is an on-vehicle multiplex

communication line with high data communication speed and excellen ...

U0155 lost communication (IPC)

U0155 lost communication (IPC)

Description

CAN (Controller Area Network) is a serial communication line for real-time

application. It is an on-vehicle multiplex

communication line with high data communication speed and excellen ...

Other materials:

Component parts

Component Parts Location

LHD

1. ABS actuator and electric unit (control

unit)

2. Front wheel sensor

3. Stop lamp switch

4. Rear wheel sensor

A. Inside engine room

B. Steering knuckle

C. Brake pedal

D. ABS warning lamp, brake warning

lamp (in combination meter)

E. Rear wheel hub and ...

B2612 steering status

DTC Logic

DTC DETECTION LOGIC

NOTE:

• If DTC B2612 is displayed with DTC U1000, first perform the trouble diagnosis

for DTC U1000. Refer to

BCS-83, "DTC Logic".

• If DTC B2612 is displayed with DTC U1010, first perform the trouble diagnosis

for DTC U1010. Refer to

BCS-84, "D ...

Sill cover

Exploded View

1. Screw grommet

2. Screw grommet

3. Sill cover

4. Wind defle

Removal and Installation

REMOVAL

1. Remove sill cover front end fixing screw (A).

2. Remove sill cover rear end fixing screw (A).

3. Remove sill cover lower side fixing screws.

4. Fully open front door and ...