Nissan Juke Service and Repair Manual : Transverse link

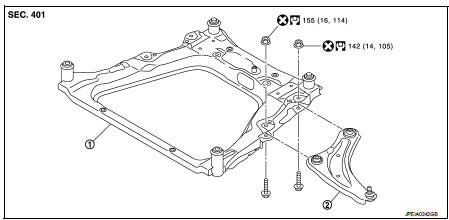

Exploded View

1. Front suspension member 2. Transverse link

: Always replace after every

: Always replace after every

disassembly.

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

Removal and Installation

REMOVAL

1. Remove tires. Refer to WT-7, "Removal and Installation".

2. Remove transverse link from steering knuckle.

• MR16DDT: Refer to FAX-11, "Removal and Installation".

• HR16DE: Refer to FAX-43, "Removal and Installation".

• K9K: Refer to FAX-68, "Removal and Installation".

3. Remove transverse link from suspension member.

INSTALLATION

Note the following, and install in the reverse order of removal.

• Never reuse transverse link mounting nut.

• Perform final tightening of bolts and nuts at the vehicle installation position (rubber bushing), under unladen conditions with tires on level ground.

• Perform inspection after installation. Refer to FSU-14, "Inspection".

Inspection

INSPECTION AFTER REMOVAL

Check the following items, and replace the parts if necessary.

Transverse Link

• Transverse link and bushing for deformation, cracks or damage.

• Ball joint boot for cracks or other damage, and also for grease leakage.

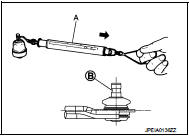

Swing Torque

1. Manually move ball stud to confirm it moves smoothly with no binding.

2. Move ball stud at least ten times by hand to check for smooth movement.

3. Hook a spring balance (A) at cutout on ball stud (B). Confirm spring balance measurement value is within specifications when ball stud begins moving.

Swing torque : Refer to FSU-22, "Ball Joint".

Measurement on spring balance : Refer to FSU-22, "Ball Joint"

• If swing torque exceeds standard range, replace transverse link assembly.

Axial End Play

1. Move ball stud at least ten times by hand to check for smooth movement.

2. Move tip of ball stud in axial direction to check for looseness.

Axial end play : Refer to FSU-22, "Ball Joint".

• If axial end play exceeds the standard value, replace transverse link assembly.

INSPECTION AFTER INSTALLATION

Check wheel alignment. Refer to FSU-7, "Inspection".

Front coil spring and strut

Front coil spring and strut

Exploded View

2WD

1. Piston rod lock nut

2. Mounting insulator

3. Mounting bearing

4. Bound bumper

5. Coil spring

6. Lower rubber seat

7. Strut

8. Steering knuckle

: N·m (kg-m, ft-lb) ...

Front stabilizer

Front stabilizer

Exploded View

1. Stabilizer bar

2. Stabilizer clamp

3. Stabilizer bushing

4. Stabilizer connecting rod

5. Strut assembly

6. Front suspension member

: N·m (kg-m, ft-lb)

Removal and Instal ...

Other materials:

Service

• Never use electrical test equipment to check SRS circuits unless instructed

to in this Service Manual.

• Before servicing the SRS, turn ignition switch OFF, disconnect battery

negative terminal and wait 3 minutes

or more. For approximately 3 minutes after the cables are removed, it is still ...

U1000 can comm circuit

Description

CAN (Controller Area Network) is a serial communication line for real time

application. It is an on-vehicle multiplex

communication line with high data communication speed and excellent malfunction

detection ability.

Many electronic control units are equipped onto a vehicle, and ...

U0141 lost communication (BCM A)

Description

CAN (Controller Area Network) is a serial communication line for real-time

application. It is an on-vehicle multiplex

communication line with high data communication speed and excellent malfunction

detection ability.

Many electronic control units are equipped onto a vehicle, and ...