Nissan Juke Service and Repair Manual : Side oil seal

Removal and Installation

REMOVAL

1. Remove front drive shafts. (MR16DDT) Refer to FAX-22, "LEFT SIDE : Removal and Installation" (LEFT SIDE) and FAX-24, "RIGHT SIDE : Removal and Installation" (RIGHT SIDE).

2. Remove front drive shafts. (K9K) Refer to FAX-78, "LEFT SIDE : Removal and Installation" (LEFT SIDE) and FAX-79, "RIGHT SIDE : Removal and Installation" (RIGHT SIDE).

3. Remove differential side oil seals (1) from clutch housing and transaxle case, using an oil seal remover.

CAUTION:

Never damage transaxle case and clutch housing.

INSTALLATION

Note the following, and install in the reverse order of removal.

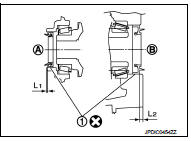

• Install differential side oil seals (1) to clutch housing and transaxle case, using the drift [Stamping number: B.vi 1666-B] of the drift set [SST: KV32500QAA].

A : Transaxle case side B : Clutch housing side

Dimension “L1” : 1.2 – 1.8 mm (0.047 – 0.071 in) Dimension “L2” : 2.7 – 3.3 mm (0.106 – 0.130 in)

CAUTION:

• Never incline differential side oil seal.

• Never damage clutch housing and transaxle case.

Inspection

INSPECTION AFTER INSTALLATION

Check the oil level and oil leakage. Refer to TM-75, "Inspection".

Position switch

Position switch

Removal and Installation

REMOVAL

1. Remove air cleaner case. (K9K) Refer to EM-280, "Removal and

Installation".

2. Remove battery. (MR16DDT) Refer to PG-124, "Removal and Installat ...

Other materials:

Power transistor

Exploded View

1. A/C unit assembly

2. Blower fan resistor*1

3. Sub harness*1

4. Power transistor*2

5. Sub harness*2

6. Blower motor

• *1: Manual air conditioner

• *2: Automatic air conditioner

Removal and Installation

REMOVAL

1. Remove instrument panel assembly. Refer to IP-13, &quo ...

Keyfob battery

Exploded View

1. Upper case

2. Key

3. Switch cover

4. Switch rubber

5. Board surface

6. Battery

7. plate

8. Lower case

9. Screw

Removal and Installation

REMOVAL

1. Remove screw (9) on the rear of keyfob.

2. Place the key with the lower case (8) facing up. Set a screw-driver wrap ...

Diagnosis and repair work flow

Work Flow

OVERALL SEQUENCE

Reference 1··· Refer to AV-33, "MODELS WITH USB CONNECTION FUNCTION : Symptom

Table" (with USB

connection function) or AV-35, "MODELS WITHOUT USB CONNECTION FUNCTION : Symptom

Table" (without

USB connection function).

DETAILED FLOW

1.CHECK ...