Nissan Juke Service and Repair Manual : Shift lock system

Component Function Check

1.CHECK SHIFT LOCK OPERATION (PART 1)

1. Turn ignition switch ON.

2. Shift the selector lever to “P” position.

3. Attempt to shift the selector lever to any other than position with the brake pedal released.

Can the selector lever be shifted to any other position? YES >> Go to TM-255, "Diagnosis Procedure".

NO >> GO TO 2.

2.CHECK SHIFT LOCK OPERATION (PART 2)

Attempt to shift the selector lever to any other than position with the brake pedal depressed.

Can the selector lever be shifted to any other position? YES >> INSPECTION END

NO >> Go to TM-255, "Diagnosis Procedure".

Diagnosis Procedure

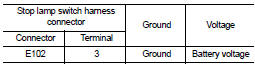

1.CHECK POWER SOURCE (PART 1)

1. Turn ignition switch OFF.

2. Disconnect stop lamp switch connector 3. Turn ignition switch ON.

4. Check the voltage between the stop lamp switch harness connector terminal and ground.

Is the inspection result normal? YES >> GO TO 2.

NO >> GO TO 9.

2.CHECK STOP LAMP SWITCH (PART 1)

Check stop lamp switch. Refer to TM-258, "Component Inspection (Stop Lamp Switch)".

Is the inspection result normal? YES >> GO TO 3.

NO >> GO TO 10.

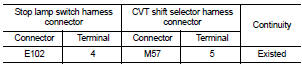

3.CHECK CIRCUIT BETWEEN STOP LAMP SWITCH AND CVT SHIFT SELECTOR (PART 1)

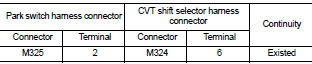

1. Disconnect CVT shift selector connector 2. Check the continuity between the stop lamp switch harness connector terminal and the CVT shift selector harness connector terminal.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair or replace the malfunctioning parts.

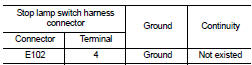

4.CHECK CIRCUIT BETWEEN STOP LAMP SWITCH AND CVT SHIFT SELECTOR (PART 1)

Check the continuity between the stop lamp switch harness connector terminal and ground.

Is the inspection result normal? YES >> GO TO 5.

NO >> Repair or replace the malfunctioning parts.

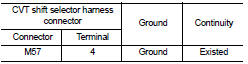

5.CHCK GROUND CIRCUIT

Check the continuity between the CVT shift selector harness connector terminal and ground.

Is the inspection result normal? YES >> GO TO 6.

NO >> Repair or replace the malfunctioning parts.

6.CHECK PART POSITION SWITCH

1. Disconnect park position switch connector.

2. Check park position switch. Refer to TM-257, "Component Inspection (Park Position Switch)".

Is the inspection result normal? YES >> GO TO 7.

NO >> Repair or replace the malfunctioning parts.

7.CHECK SHIFT LOCK SOLENOID

1. Disconnect shift lock solenoid connector.

2. Check shift lock solenoid. Refer to TM-257, "Component Inspection (Shift Lock Solenoid)".

Is the inspection result normal? YES >> GO TO 8.

NO >> Repair or replace the malfunctioning parts.

8.CHECK CVT SHIFT SELECTOR HARNESS

Check CVT shift selector harness. Refer to TM-257, "Component Inspection (CVT Shift Selector Harness)".

Is the inspection result normal? YES >> Check intermittent incident. Refer to GI-42, "Intermittent Incident".

NO >> Repair or replace the malfunctioning parts.

9.DETECT MALFUNCTIONING ITEM

Check the following items: • Open or short circuit of the harness between ignition switch and stop lamp switch connector. Refer to PG-15, "Wiring Diagram - IGNITION POWER SUPPLY -".

• Ignition switch

• 10A fuse [No.3, fuse block (J/B)]. Refer to PG-22, "Fuse, Connector and

Terminal Arrangement".

Is the inspection result normal? YES >> Check intermittent incident. Refer to GI-42, "Intermittent Incident".

NO >> Repair or replace the malfunctioning parts.

10.CHECK INSTALLATION POSITION OF STOP LAMP SWITCH

Adjust stop lamp switch position. Refer to BR-9, "Inspection and Adjustment" (LHD) or BR-77, "Inspection and Adjustment" (RHD).

>> GO TO 11.

11.CHECK STOP LAMP SWITCH (PART 2)

Check stop lamp switch. Refer to TM-258, "Component Inspection (Stop Lamp Switch)".

Is the inspection result normal? YES >> INSPECTION END

NO >> Repair or replace the malfunctioning parts.

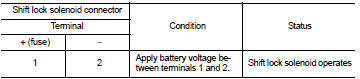

Component Inspection (Shift Lock Solenoid)

1.CHECK SHIFT LOCK SOLENOID

Apply voltage to terminals of shift lock solenoid connector and check that shift lock solenoid is activated.

CAUTION:

• Connect the fuse between the terminals when applying the voltage.

• Never cause shorting between terminals.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace the shift lock unit. Refer to TM-271, "Disassembly and Assembly".

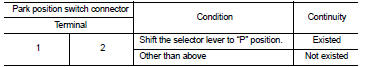

Component Inspection (Park Position Switch)

1.CHECK PARK POSITION SWITCH

Check the continuity between park position switch connector terminals.

CAUTION:

• Connect the fuse between the terminals when applying the voltage.

• Never cause shorting between terminals.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace the park position switch. Refer to TM-271, "Disassembly and Assembly".

Component Inspection (CVT Shift Selector Harness)

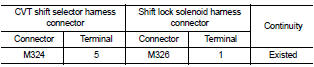

1.CHECK CVT SHIFT SELECTOR HARNESS (PART 1)

Check the continuity between the CVT shift selector harness connector terminal and the shift lock solenoid harness connector terminal.

Is the inspection result normal? YES >> GO TO 2.

NO >> Replace the CVT shift selector harness. Refer to TM-271, "Disassembly and Assembly".

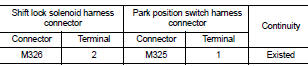

2.CHECK CVT SHIFT SELECTOR HARNESS (PART 2)

Check the continuity between the shift lock solenoid harness connector terminal and the park position switch harness connector terminal.

Is the inspection result normal? YES >> GO TO 3.

NO >> Replace the CVT shift selector harness. Refer to TM-271, "Disassembly and Assembly".

3.CHECK CVT SHIFT SELECTOR HARNESS (PART 3)

Check the continuity between the park switch harness connector terminal and the CVT shift selector harness connector terminal.

Is the inspection result normal? YES >> GO TO 4.

NO >> Replace the CVT shift selector harness. Refer to TM-271, "Disassembly and Assembly".

4.CHECK CVT SHIFT SELECTOR HARNESS (PART 4)

Check harness cladding CVT shift selector harness for damage.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace the CVT shift selector harness. Refer to TM-271, "Disassembly and Assembly".

Component Inspection (Stop Lamp Switch)

1.CHECK STOP LAMP SWITCH

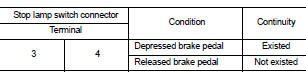

Check the continuity between the stop lamp switch connector terminals.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace stop lamp switch. Refer to BR-21, "Removal and Installation" (LHD) or BR-89, "Removal and Installation" (RHD).

Shift position indicator circuit

Shift position indicator circuit

Description

• TCM sends position indicator signals to combination meter by CAN

communication line.

• Manual mode switch position is indicated on shift position indicator

Component Function Check

...

Symptom diagnosis

Symptom diagnosis

SYSTEM SYMPTOM

Symptom Table

The diagnostics item numbers show the sequence for inspection. Inspect in

order from item 1.

...

Other materials:

Key interlock cable

Exploded View

1. CVT shift selector assembly

2. Key interlock cable

A: Key cylinder

B: Clip

C: Clip

Removal and Installation

REMOVAL

CAUTION:

Always apply the parking brake before performing removal and installation.

1. Shift the selector lever to the “P” position.

2. Remove the sele ...

B1136 side air bag module LH

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.CHECK SELF-DIAG RESULT

With CONSULT-III

1. Turn ignition switch ON.

2. Perform “Self Diagnostic Result” mode of “AIR BAG” using CONSULT-III.

Without CONSULT-III

1. Turn ignition switch ON.

2. Check the air bag warning lamp statu ...

Ignition signal

Component Function Check

1.INSPECTION START

Turn ignition switch OFF, and restart engine.

Does the engine start?

YES >> GO TO 2.

NO >> Proceed to EC-414, "Diagnosis Procedure".

2.IGNITION SIGNAL FUNCTION

With CONSULT-III

1. Perform “POWER BALANCE” in “ACTIVE TEST” ...