Nissan Juke Service and Repair Manual : Removal and installation

REAR WHEEL HUB

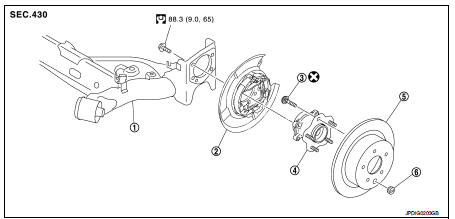

Exploded View

1. Rear suspension beam

2. Rear brake assembly

3. Hub bolt

4. Wheel hub assembly (Bearing-integrated

type)

5. Disc rotor

6. Plug

: Always replace after every

: Always replace after every

disassembly.

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

Removal and Installation

REMOVAL

1. Remove tires. Refer to WT-7, "Removal and Installation".

2. Remove wheel sensor. Refer to BRC-86, "REAR WHEEL SENSOR : Removal and Installation" (Without ESP), BRC-227, "REAR WHEEL SENSOR : Removal and Installation" (With ESP).

3. Remove caliper assembly. Hang caliper assembly in a place where it will not interfere with work. Refer to BR-65, "BRAKE CALIPER ASSEMBLY : Removal and Installation" (LHD), BR-131, "BRAKE CALIPER ASSEMBLY : Removal and Installation" (RHD).

CAUTION:

Never depress brake pedal while brake caliper is removed.

4. Remove disc rotor. If disc rotor cannot be removed, remove as follows.

CAUTION:

• Parking brake completely in the released position.

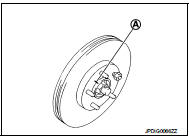

• Put matching marks (A) on the wheel hub assembly and the disc rotor before removing the disc rotor.

• Never drop disc rotor.

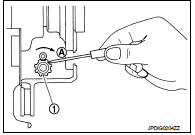

a. Fix the disc rotor with wheel nuts and remove the adjusting hole plug.

b. Using suitable tool, rotate adjuster (1) in the direction (A) to retract and loosen brake shoe.

5. Remove wheel hub assembly.

6. Remove hub bolts from wheel hub assembly, using a press.

CAUTION:

• Remove hub bolt only when necessary.

• Never hammer the hub bolt to avoid impact to the wheel hub assembly.

• Pull out the hub bolt in a direction perpendicular to the wheel hub assembly.

7. Perform inspection after removal. Refer to RAX-6, "Inspection".

INSTALLATION

Note the following, and install in the reverse order of removal.

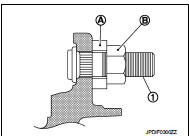

• Place a washer (A) as shown in the figure to install the hub bolts (1) by using the tightening force of the nut (B).

CAUTION:

• Check that there is no clearance between wheel hub assembly

and hub bolt.

• Never reuse hub bolt.

• Align the matching marks that have been made during removal when reusing the disc rotor.

• Perform inspection after installation. Refer to RAX-6, "Inspection".

Inspection

INSPECTION AFTER REMOVAL

Check the wheel hub assembly for wear, cracks, and damage. Replace if necessary.

INSPECTION AFTER INSTALLATION

1. Check wheel sensor harness for proper connection. BRC-85, "REAR WHEEL SENSOR : Exploded View" (Without ESP), BRC-225, "REAR WHEEL SENSOR : Exploded View" (With ESP).

2. Adjust parking brake operation (stroke). Refer to PB-2, "Inspection and Adjustment".

3. Check wheel alignment. Refer to RSU-20, "Inspection".

Periodic maintenance

Periodic maintenance

REAR WHEEL HUB

Inspection

COMPONENT PART

Check the mounting conditions (looseness, back lash) of each component and

component conditions (wear,

damage) are normal.

WHEEL HUB ASSEMBLY (BEARING ...

Service data and specifications (SDS)

Service data and specifications (SDS)

Wheel Bearing

...

Other materials:

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”,

used along

with a front seat belt, helps to reduce the risk or severity of injury to the

driver and front passenger for certain

types of collision. Information necessary to service the system safely is

include ...

Precaution Necessary for Steering Wheel Rotation after Battery Disconnect

NOTE:

• Before removing and installing any control units, first turn the ignition

switch to the LOCK position, then disconnect

both battery cables.

• After finishing work, confirm that all control unit connectors are connected

properly, then re-connect both

battery cables.

• Always use CONS ...

Additional service when replacing ECM

Description

When replacing ECM, this procedure must be performed.

Work Procedure

1.PRECONDITIONING

• Connect a CONSULT-III

• Connect a battery charger

• Electric load switch is OFF

• Wait for the engine to cool [engine coolant temperature < 60?°C (140?°F) and air

temperature < 50?°C ( ...