Nissan Juke Service and Repair Manual : Removal and Installation

REMOVAL

1. Separate the rear propeller shaft. Refer to DLN-121, "Removal and Installation".

2. Remove right side drive shaft. Refer to FAX-24, "RIGHT SIDE : Removal and Installation".

3. Remove catalyst convertor support bracket (RH). EM-35, "4WD : Removal and Installation".

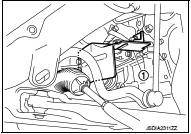

4. Remove heat insulator (1).

5. Remove transfer gusset (1).

6. Remove catalyst convertor upport bracket rear. EM-59, "4WD : Removal and Installation".

7. Remove rear torque rod and rear torque rod bracket. Refer to EM-59, "4WD : Removal and Installation".

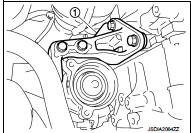

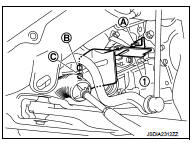

8. Remove the mounting bolts of transaxle assembly and transfer assembly.

9. Remove transfer assembly from the vehicle.

: Vehicle front

: Vehicle front

CAUTION:

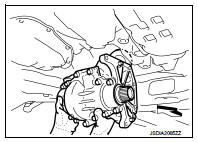

Never damage ring gear shaft.

INSTALLATION

Note the following, and install in the reverse order of removal.

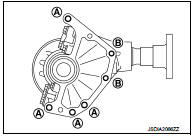

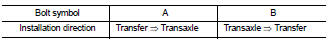

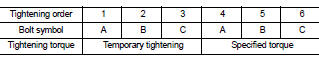

• When installing the transfer to the transaxle, install the mounting bolts following the standard below.

CAUTION:

• When installing transfer assembly to transaxle assembly,

replace the side oil seal (transfer joint). Refer to TM-292,

"Removal and Installation".

• Never damage side oil seal (the joint part of transfer).

• When installing heat insulator (1), install the mounting bolts and nut following procedure.

• Check oil level and check for oil leakage after installation. Refer to DLN-90, "Inspection".

Exploded View

Exploded View

1. Transfer gusset

2. Transfer assembly

3. Heat insulator

: Vehicle front

: N·m (kg-m, ft-lb)

...

Other materials:

Camshaft

Exploded View

1. Camshaft position sensor (PHASE)

2. O-ring

3. Camshaft bracket

4. Camshaft (EXH)

5. Camshaft sprocket (EXH)

6. Camshaft sprocket (INT)

7. Camshaft (INT)

8. Valve lifter (EXH)

9. Valve lifter (INT)

10. Signal plate (INT)

11 Signal plate (EXH)

A.Tightening must be ...

Door lock actuator

Driver side

DRIVER SIDE : Component Function Check

1.CHECK FUNCTION

1. Select “DOOR LOCK” of “BCM” using CONSULT-III.

2. Select “DOOR LOCK” in “ACTIVE TEST” mode.

3. Check that the function operates normally according to the following

conditions.

Is the inspection result normal?

YES >& ...

Refilling

1. Install reservoir tank if removed and radiator drain plug.

CAUTION:

Be sure to clean drain plug and install with new O-ring.

Radiator drain plug : Refer to CO-42, "Exploded View".

• If water drain plugs on cylinder block are removed, close and tighten them.

Refer to EM-228, &quo ...