Nissan Juke Service and Repair Manual : Rear washer nozzle and tube

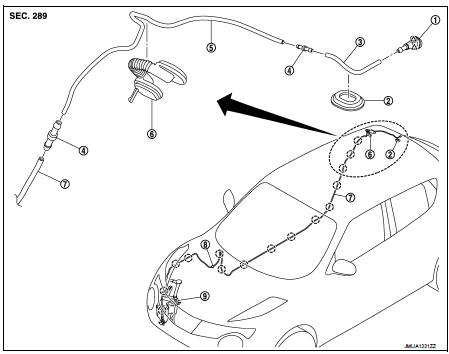

Hydraulic Layout

1. Rear washer nozzle

2. Plug

3. Rear washer tube

4. Joint

5. Second washer tube

6. Back door seal rubber

7. Front washer tube

: Clip

: Clip

: Pawl

: Pawl

Removal and Installation

REMOVAL

1. Remove luggage side upper finisher RH. Refer to INT-32, "LUGGAGE SIDE UPPER FINISHER : Removal and Installation".

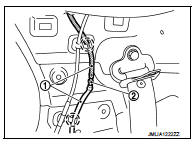

2. Disconnect rear washer tube (2) fixing clip and then remove rear washer tube joint (2) from rear washer tube.

: Clip

: Clip

3. Fully open back door.

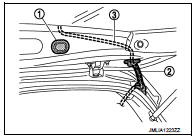

4. Remove back door seal rubber (2), and then remove rear washer tube (3) from back door seal rubber.

5. Remove plug (1).

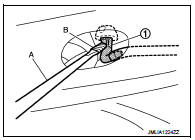

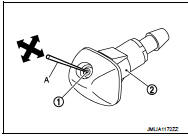

6. Disengage rear washer nozzle (1) fixing pawl with a flat-bladed screwdriver (A) and remove the rear washer nozzle.

CAUTION:

Wrap the flat-bladed screwdriver into a protective tape (B)

to protect the part from damage.

7. Remove rear washer nozzle from the rear washer tube.

INSTALLATION

Install in the reverse order of removal.

Inspection and Adjustment

INSPECTION

Washer Nozzle Inspection Check that air can pass through the hose by blowing forward (toward the nozzle), and check that air cannot pass through by sucking.

ADJUSTMENT

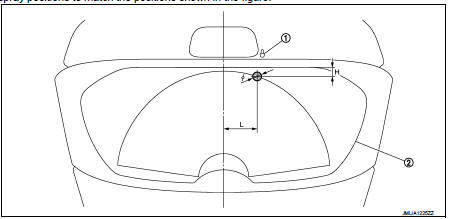

Washer Nozzle Spray Position adjustment Adjust spray positions to match the positions shown in the figure

1. Rear washer nozzle 2. Black print frame line

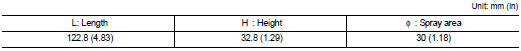

Insert a needle or similar object (A) into the spray opening (1) and move up/down and left/right to adjust the spray position.

NOTE

:

If wax or dust gets into the spray opening of rear washer nozzle (2),

remove wax or dust with a needle or small pin.

Rear wiper motor

Rear wiper motor

Exploded View

1. Rear wiper motor

2. Rear wiper blade

3. Rear wiper arm

4. Rear wiper arm cover

5. Rear wiper pivot seal

A : Model for cold areas

: Pawl

: N·m (kg-m, in-lb)

: N·m (kg-m, ...

Defogger

Defogger

...

Other materials:

P0300, P0301, P0302, P0303, P0304 misfire

DTC Logic

DTC DETECTION LOGIC

When a misfire occurs, engine speed will fluctuate. If the engine speed

fluctuates enough to cause the crankshaft

position (CKP) sensor (POS) signal to vary, ECM can determine that a misfire is

occurring.

The misfire detection logic consists of the following t ...

P17Ba primary pressure solenoid

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PREPARATION BEFORE WORK

If another "DTC CONFIRMATION PROCEDURE" occurs just before, turn ignition

switch OFF and wait for at

least 10 seconds, then perform the next test.

>> GO TO 2.

2.CHECK DTC DETECTION

1. S ...

B2626 outside antenna

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PERFORM DTC CONFIRMATION PROCEDURE

1. Disconnect outside key antenna (driver side) connector.

2. Perform “INTELLIGENT KEY” Self Diagnostic Result.

Is outside key antenna DTC detected?

YES >> Refer to DLK-61, "Diagnosis ...