Nissan Juke Service and Repair Manual : Rear disc brake

Brake pad : Inspection and Adj

INSPECTION

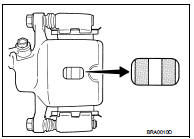

Check brake pad wear thickness from an inspection hole on cylinder body. Check using a scale if necessary.

Wear thickness : Refer to BR-137, "Rear Disc Brake".

ADJUSTMENT

Burnish contact surfaces between disc rotor and brake pads according to the following procedure after refinishing or replacing brake pads, or if a soft pedal occurs at very low mileage.

CAUTION:

• Be careful of vehicle speed because the brake does not operate firmly/securely

until pads and disc

rotor are securely fitted.

• Only perform this procedure under safe road and traffic conditions. Use extreme caution.

1. Drive vehicle on straight, flat road.

2. Depress brake pedal with the power to stop vehicle within 3 to 5 seconds until the vehicle stops.

3. Drive without depressing brake for a few minutes to cool the brake.

4. Repeat steps 1 to 3 until pad and disc rotor are securely fitted.

Disc rotor : Inspection and Adjustment

INSPECTION

Appearance

Check surface of disc rotor for uneven wear, cracks, and serious damage. Replace

it if necessary.

• 2WD: Refer to RAX-5, "Removal and Installation".

• 4WD: Refer to RAX-14, "Removal and Installation".

Runout

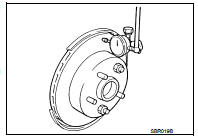

1. Fix the disc rotor to the wheel hub and bearing assembly with

wheel nuts (2 points at least).

2. Check the wheel bearing axial end play before the inspection.

• 2WD: Refer to RAX-4, "Inspection".

• 4WD: Refer to RAX-12, "Inspection".

3. Inspect the runout with a dial indicator to measure at 10 mm (0.39 in) inside the disc edge.

Runout (with it attached to the vehicle) : Refer to BR-137, "Rear Disc Brake".

4. Find the installation position that has a minimum runout by shifting the disc rotor-to-wheel hub and bearing assembly installation position by one hole at a time if the runout exceeds the limit value.

• Refinish the disc rotor if the runout is outside the limit even after performing the above operation.

CAUTION:

• Check in advance that the thickness of the disc rotor is wear thickness + 0.3

mm (0.012 in) or more.

• If the thickness is less than wear thickness + 0.3 mm (0.012 in), replace the disc rotor.

- 2WD: Refer to RAX-5, "Removal and Installation".

- 4WD: Refer to RAX-14, "Removal and Installation".

Wear thickness : Refer to BR-137, "Rear Disc Brake".

Thickness

Check the thickness of the disc rotor using a micrometer. Replace

the disc rotor if the thickness is below the wear limit.

• 2WD: Refer to RAX-5, "Removal and Installation".

• 4WD: Refer to RAX-14, "Removal and Installation".

Wear thickness : Refer to BR-137, "Rear Disc Brake".

ADJUSTMENT

Burnish contact surfaces between disc rotors and brake pads according to the following procedure after refinishing or replacing disc rotor, or if a soft pedal occurs at very low mileage.

CAUTION:

• Be careful of vehicle speed because the brake does not operate firmly/securely

until pad and disc

rotor are securely fitted.

• Only perform this procedure under safe road and traffic conditions. Use extreme caution.

1. Drive vehicle on straight, flat road.

2. Depress brake pedal with the power to stop vehicle within 3 to 5 seconds until the vehicle stops.

3. Drive without depressing brake for a few minutes to cool the brake.

4. Repeat steps 1 to 3 until pad and disc rotor are securely fitted.

Front disc brake

Front disc brake

Brake pad : Inspection and Adjustment

INSPECTION

Check brake pad wear thickness from an inspection hole on cylinder

body. Check using a scale if necessary.Wear thickness : Refer to BR-137, "Fr ...

Other materials:

U1000 can comm circuit

Description

CAN (Controller Area Network) is a serial communication system for real time

application. It is an on-vehicle

multiplex communication system with high data communication speed and excellent

error detection ability.

Many electronic control units are equipped onto vehicles, and ea ...

P0560 battery voltage

DTC Logic

DTC DETECTION LOGIC

NOTE:

When IPDM E/R DTC is indicated with DTC P0560, IPDM E/R DTC must be checked

first.

Diagnosis Procedure

1.CHECK BATTERY VOLTAGE

1. Turn ignition switch ON.

2. Check battery voltage.

Voltage: Above 11 V

Is the inspection result normal?

YES >> GO ...

Sun visors

TILT OPERATION

Push the lock lever down 1 and adjust the steering wheel up or down 2 to the

desired position.

Pull the lock lever up 3 securely to lock the steering wheel in place.

1. To block out glare from the front, swing down the sun visor1 .

2. To block glare from the side, remove the ...