Nissan Juke Service and Repair Manual : Radiator

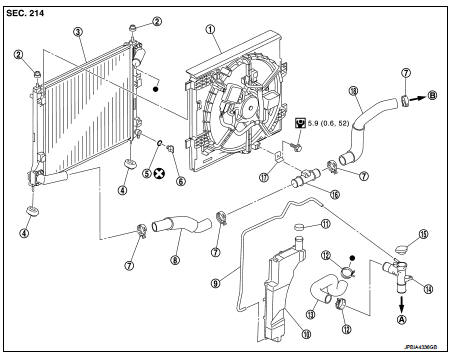

Exploded View

1. Cooling fan assembly

2. Mounting rubber (upper)

3. Radiator

4. Mounting rubber (lower)

5. O-ring 6. Drain plug

7. Clamp 8. Radiator hose (lower) (LH)

9. Reservoir tank hose

10. Reservoir tank

11. Reservoir tank cap

12. Clamp

13. Radiator hose (upper)

14. Water outlet adaptor

15. Radiator cap

16. Radiator hose pipe

17. Bracket

18. Radiator hose (lower) (RH)

A. To water outlet

B. To water inlet

: N·m (kg-m, in-lb)

: N·m (kg-m, in-lb)

: Always replace after every

: Always replace after every

disassembly.

Removal and Installation

REMOVAL

WARNING:

• Never remove radiator cap when engine is hot. Serious burns may occur from

high-pressure engine

coolant escaping from radiator.

• Wrap a thick cloth around the radiator cap. Slowly turn it a quarter of a turn to release built-up pressure.

Then turn it all the way.

1. Drain engine coolant from radiator. Refer to CO-11, "Draining".

CAUTION

:

• Perform this step when the engine is cold.

• Never spill engine coolant on drive belt.

2. Remove engine cover. Refer to EM-25, "Exploded View".

3. Remove engine under cover.

4. Remove radiator hose (upper and lower).

5. Remove front bumper. Refer to EXT-12, "Exploded View".

6. Remove radiator core support upper. Refer to DLK-149, "MR16DDT : Exploded View".

7. Disconnect cooling fan harness connector.

8. Remove reservoir tank.

9. Remove cooling fan assembly.

CAUTION:

Be careful not to damage or scratch the radiator core.

10. Remove condenser from radiator and temporarily fasten it on vehicle with a rope.

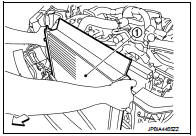

11. Pull up and remove the radiater assembly (1).

CAUTION:

Be careful not to damage radiator core and condenser

assembly core.

INSTALLATION

Install in the reverse order of removal.

INSTALLATION

Note the following, and install in the reverse order of removal.

NOTE

:

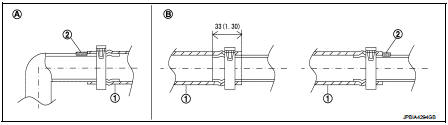

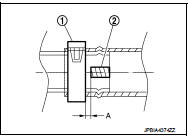

• Insert the radiator hose (1) all the way to the stopper (2) or by 33 mm (1.30 in) (hose without a stopper).

Unit mm (in)

A. Radiator side

B. Engine side

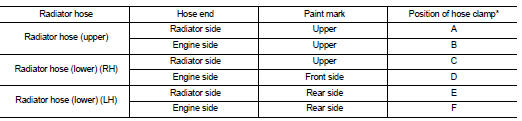

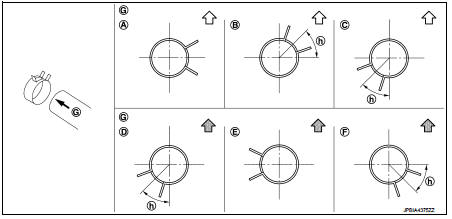

• For the orientation of the hose clamp pawl, refer to the figure.

*Refer to the illustrations for the specific position each hose clamp tab.

G. View

G h. 45°

: Vehicle upper

: Vehicle upper

: Vehicle front

: Vehicle front

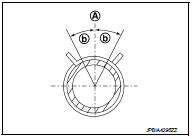

• The angle (b) created by the hose clamp pawl and the specified line (A) must be within ±15° as shown in the figure.

• To install hose clamps (1), check that the dimension (A) from the end of the paint mark (2) on the radiator hose to the hose clamp is within the reference value.

Dimension “A” 3 mm

Inspection

INSPECTION AFTER INSTALLATION

• Check for leakage of engine coolant using the radiator cap tester adapter (commercial service tool) and the radiator cap tester (commercial service tool). Refer to CO-11, "Inspection".

• Start and warm up the engine. Check visually that there is no leakage of engine coolant.

Cooling fan

Cooling fan

Exploded View

1. Fan motor

2. Fan shroud

3. Cooling fan

A. Apply on fan motor shaft

: N·m (kg-m, in-lb)

: Apply genuine high strength thread

locking sealant or equivalent.

Removal and Ins ...

Other materials:

Direct injection gasoline system

Direct injection gasoline system : System Diagram

Direct injection gasoline system : System Description

INPUT/OUTPUT SIGNAL CHART

*1: This sensor is not used to control the engine system under normal

conditions.

*2: CVT models

*3: M/T models

*4: ECM determines the start signal status by ...

Door cable

Exploded View

LEFT SIDE

1. A/C unit assembly

2. Intake door lever

3. Intake door link

4. Intake door cable

5. Air mix door cable

6. Air mix door link

7. Air mix door rod

8. Lower air mix door lever

9. Upper air mix door lever

10. Max. cool door

A. To A/C control

RIGHT SIDE

...

C1609 vehicle speed signal

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always turn

ignition switch OFF and

wait at least 10 seconds before conducting the next test.

>> GO TO 2.

2.DTC REPRODUCTION PROCEDURE

With ...