Nissan Juke Service and Repair Manual : Camshaft valve clearance

Valve Clearance

CHECKING AND ADJUSTING THE VALVE CLEARANCE

1. Install the tappet.

2. Install the camshaft.

3. Install the camshaft brackets.

: 11 N·m (1.1 kg-m, 8 ft-lb)

: 11 N·m (1.1 kg-m, 8 ft-lb)

4. Place the valves of the cylinder concerned at the “end of exhaust - beginning of inlet” position and check the clearance (X).

NOTE

:

Dimension (Y) corresponds to the tappet thickness sizes (there

are 25 sizes at the service parts).

5. Compare the values recorded with the values specified, then replace the tappets which are not within tolerance.

Clearance, when the engine cold: Intake : 0.125 - 0.25 mm (0.0049 - 0.0098 in) Exhaust : 0.325 - 0.45 mm (0.0128 - 0.0177 in)

6. Remove the camshaft brackets.

7. Remove the camshaft.

8. Remove the tappet not within tolerance.

Determining dimension Y.

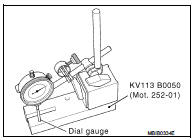

Set up the following assembly using KV113B0050 (Mot. 252-01) (Commercial service tool) or equivalent tool and dial gauge, then calibrate the gauge.

9. Raise the gauge extension (without modifying the position of the magnetic support/gauge assembly), then slide in the tappet to be measured.

• Note dimension (Y) and repeat the operation for the tappets where the valve clearance is not within tolerance.

• Refer to the Replacement Parts Catalogue for the vehicle concerned to select the various thicknesses of the tappet(s).

10. Check the valve clearance again.

11. Remove the camshaft brackets.

12. Remove the camshaft.

13. Remove the tappet(s) not within tolerance.

14. Grease the underside of the tappets and the camshaft brackets.

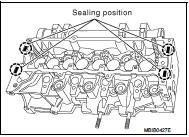

15. Degrease the gasket faces (of the cylinder head and brackets 1 and 6). They should be clean, dry and free from grease (in particular, remove finger marks).

16. Lay four beads of Loctite with a width of 1 mm (0.04 in) on brackets 1 and 6 of the cylinder head.

17. Install the camshaft.

18. Install the camshaft brackets (these are numbered from 1 to 6 and bearing (1) should be positioned on the flywheel end).

: 11 N·m (1.1 kg-m, 8 ft-lb)

: 11 N·m (1.1 kg-m, 8 ft-lb)

Basic inspection

Basic inspection

...

Symptom diagnosis

Symptom diagnosis

Noise, vibration and harshnesS (NVH) Troubleshooting

NVH Troubleshooting - Engine Noise

Use the Chart Below to Help You Find the Cause

of the Symptom

1. Locate the area where noise occurs.

2. C ...

Other materials:

P0403 EGR volume control valve

DTC Logic

DTC DETECTION LOGIC

Diagnosis Procedure

1.CHECK EGR VOLUME CONTROL VALVE CONTROL CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect EGR volume control valve harness connector and ECM harness

connector.

3. Check the continuity between EGR volume control valve terminal harness

co ...

Operating tips

• When the shift lever is shifted to the R (Reverse) position, the monitor screen

automatically changes to the RearView Monitor mode. However, the radio can be heard.

• When the view is switched, the display images on the screen may be displayed with

some delay.

• When the temperature is extre ...

B26FB clutch switch

DTC Logic

DTC DETECTION LOGIC

NOTE:

• If DTC B26FB is displayed with DTC U1000, first perform the trouble diagnosis

for DTC U1000. Refer to

BCS-83, "DTC Logic".

• If DTC B26FB is displayed with DTC U1010, first perform the trouble diagnosis

for DTC U1010. Refer to

BCS-84, "D ...