Nissan Juke Service and Repair Manual : Precautions

Liquid Gasket

REMOVAL OF LIQUID GASKET SEALING

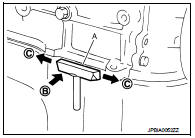

• After removing mounting nuts and bolts, separate the mating surface using the seal cutter [SST: KV10111100 (J-37228)] (A) and remove old liquid gasket sealing.

CAUTION:

Be careful not to damage the mating surfaces.

• Tap the seal cutter [SST: KV10111100 (J-37228)] to insert it (B), and then slide it (C) by tapping on the side as shown in the figure.

• In areas where the seal cutter [SST: KV10111100 (J-37228)] is difficult to use, lightly tap the parts using a plastic hammer to remove it.

CAUTION:

If for some unavoidable reason tool such as a screwdriver is

used, be careful not to damage the mating surfaces.

LIQUID GASKET APPLICATION PROCEDURE

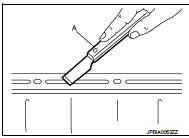

1. Using a scraper (A), remove old liquid gasket adhering to the liquid gasket application surface and the mating surface.

• Remove liquid gasket completely from the groove of the liquid gasket application surface, mounting bolts, and bolt holes.

2. Wipe the liquid gasket application surface and the mating surface with white gasoline (lighting and heating use) to remove adhering moisture, grease and foreign materials.

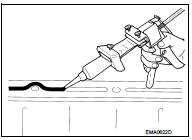

3. Attach liquid gasket tube to the tube presser (commercial service tool).

Use Genuine Liquid Gasket or equivalent.

4. Apply liquid gasket without gaps to the specified location according to the specified dimensions.

• If there is a groove for liquid gasket application, apply liquid gasket to the groove.

• As for bolt holes (B), normally apply liquid gasket inside the holes. Occasionally, it should be applied outside the holes.

Check to read the text of this manual.

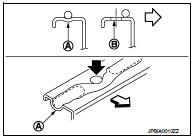

A : Groove

: Inside

: Inside

• Within five minutes of liquid gasket application, install the mating component.

• If liquid gasket protrudes, wipe it off immediately.

• Do not retighten mounting bolts or nuts after the installation.

• After 30 minutes or more have passed from the installation, fill engine oil and engine coolant.

CAUTION:

If there are specific instructions in this manual, observe them.

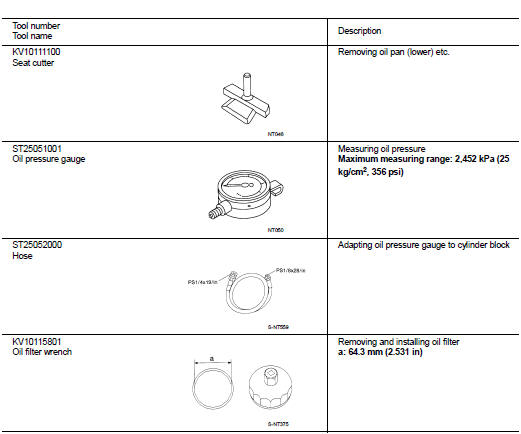

Special Service Tools

Commercial Service Tools

Description

Description

Engine Lubrication System

Engine Lubrication System Schematic

...

Other materials:

Recommended fluids and lubricants

Fluids and Lubricants

*1: For additional information, see “SAE Viscosity Number”.

*2: Use Genuine NISSAN Engine Coolant or equivalent in its quality, in order to

avoid possible aluminium corrosion within the engine

cooling system caused by the use of non-genuine engine coolant. Note that any ...

B1186, B1187, B1188, B1189, B1190, B1191 diagnosis sensor unit

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.CHECK SELF-DIAG RESULT

With CONSULT-III

1. Turn ignition switch ON.

2. Perform “Self Diagnostic Result” mode of “AIR BAG” using CONSULT-III.

Without CONSULT-III

1. Turn ignition switch ON.

2. Check the air bag warning lamp statu ...

Precaution Necessary for Steering Wheel Rotation after Battery Disconnect

NOTE:

• Before removing and installing any control units, first turn the ignition

switch to the LOCK position, then disconnect

both battery cables.

• After finishing work, confirm that all control unit connectors are connected

properly, then re-connect both

battery cables.

• Always use CONS ...