Nissan Juke Service and Repair Manual : Position switch

Removal and Installation

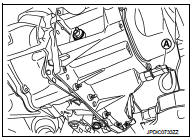

REMOVAL

1. Drain gear oil. Refer to TM-22, "Draining".

2. Disconnect position switch connector (A).

3. Remove position switch from transaxle case.

INSTALLATION

1. Apply recommended sealant to threads of position switch.

• Use Genuine Liquid Gasket, Three Bond 1215 or an equivalent.

CAUTION:

Remove old sealant and oil adhering to threads.

2. Install position switch to transaxle case.

3. Tighten position switch to the specified torque. Refer to TM-33, "Exploded View".

4. Refill gear oil. Refer to TM-22, "Refilling".

Inspection

INSPECTION AFTER INSTALLATION

• Check continuity between position switch terminals. Refer to TM-20, "BACK-UP LAMP SWITCH : Component Inspection" (Back-up lamp switch) and TM-20, "PARK/NEUTRAL POSITION (PNP) SWITCH : Component Inspection" (PNP switch).

• Check the oil leakage and the oil level. Refer to TM-22, "Inspection".

Side oil seal

Side oil seal

Removal and Installation

REMOVAL

1. Remove front drive shafts. Refer to FAX-53, "Removal and Installation".

2. Remove differential side oil seals (1) from clutch housing and

transaxle ca ...

Control linkage

Control linkage

Exploded View

1. Bracket

2. Selector cable

3. Shifter lever A

4. Selector lever

5. Cable mounting bracket

6. Tapping bolt

7. Shifter cable

8. Grommet

9. M/T shift selector assembly

1 ...

Other materials:

P0171 fuel injection system function

DTC Logic

DTC DETECTION LOGIC

With the Air/Fuel Mixture Ratio Self-Learning Control, the actual mixture

ratio can be brought closely to the

theoretical mixture ratio based on the mixture ratio feedback signal from the

A/F sensor 1. The ECM calculates

the necessary compensation to correct the ...

Service data and specifications (SDS

Compressor

Lubricant

Refrigerant

Engine Idling Speed

Refer to EC-449, "Idle Speed".

Belt Tension

Refer to EM-20, "Checking". ...

C1164, C1165 CV system

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always turn

ignition switch OFF and

wait at least 10 seconds before conducting the next test.

>> GO TO 2.

2.CHECK DTC DETECTION

With CONSULT ...