Nissan Juke Service and Repair Manual : Parking lamp circuit

Without daytime running light system

WITHOUT DAYTIME RUNNING LIGHT SYSTEM : Component Function Check

1.CHECK PARKING LAMP OPERATION

CONSULT-III ACTIVE TEST

CONSULT-III ACTIVE TEST

1. Select “EXTERNAL LAMPS” of IPDM E/R active test item.

2. With operating the test items, check that the parking lamp is turned ON.

TAIL : Parking lamp ON Off : Parking lamp OFF

Is the inspection result normal? YES >> Parking lamp circuit is normal.

NO >> Refer to EXL-60, "WITH DAYTIME RUNNING LIGHT SYSTEM : Diagnosis Procedure".

WITHOUT DAYTIME RUNNING LIGHT SYSTEM : Diagnosis Procedure

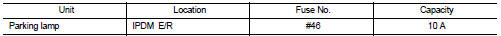

1.CHECK PARKING LAMP FUSE

1. Turn ignition switch OFF.

2. Check that the following fuses are not fusing.

Is the inspection result normal? YES >> GO TO 3.

NO >> GO TO 2.

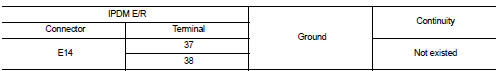

2.CHECK PARKING LAMP SHORT CIRCUIT

1. Disconnect the following connectors.

- IPDM E/R

- Parking lamp

- Rear combination lamp (RH)

- License plate lamp

2. Check continuity between IPDM E/R harness connector and ground.

Is the inspection result normal? YES >> Replace fuse. (Replace IPDM E/R if fusing is found again.) NO >> Repair or replace harness. And then replace the fuse.

3.CHECK PARKING LAMP BULB

Check applicable lamp bulb.

Is the inspection result normal? YES >> GO TO 4.

NO >> Replace bulb.

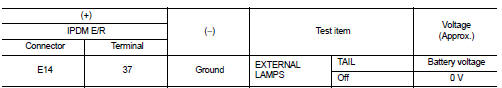

4.CHECK PARKING LAMP OUTPUT VOLTAGE

CONSULT-III ACTIVE TEST

CONSULT-III ACTIVE TEST

1. Disconnect parking lamp connector.

2. Turn ignition switch ON.

3. Select “EXTERNAL LAMPS” of IPDM E/R active test item.

4. With operating the test items, check voltage between IPDM E/R harness connector and ground.

Is the inspection result normal? YES >> GO TO 5.

NO >> Replace IPDM E/R.

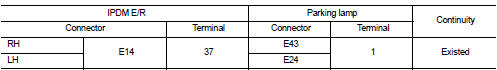

5.CHECK PARKING LAMP OPEN CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R connector.

3. Check continuity between IPDM E/R harness connector and parking lamp harness connector.

Is the inspection result normal? YES >> GO TO 6.

NO >> Repair or replace harness.

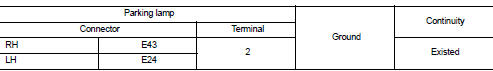

6.CHECK PARKING LAMP GROUND OPEN CIRCUIT

Check continuity between parking lamp harness connector and ground.

Is the inspection result normal? YES >> Check corresponding bulb socket and harness. Repair or replace if necessary.

NO >> Repair or replace harness.

With daytime running light system

WITH DAYTIME RUNNING LIGHT SYSTEM : Component Function Check

1.CHECK PARKING LAMP OPERATION

CONSULT-III ACTIVE TEST

CONSULT-III ACTIVE TEST

1. Select “EXTERNAL LAMPS” of IPDM E/R active test item.

2. With operating the test items, check that the parking lamp is turned ON.

TAIL : Parking lamp ON Off : Parking lamp OFF

Is the inspection result normal? YES >> Parking lamp circuit is normal.

NO >> Refer to EXL-60, "WITH DAYTIME RUNNING LIGHT SYSTEM : Diagnosis Procedure".

WITH DAYTIME RUNNING LIGHT SYSTEM : Diagnosis Procedure

1.CHECK PARKING LAMP BULB

Check applicable lamp bulb.

Is the inspection result normal? YES >> GO TO 2.

NO >> Replace bulb.

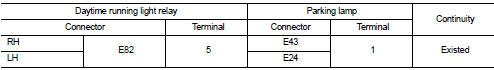

2.CHECK PARKING LAMP OPEN CIRCUIT

1. Turn ignition switch OFF.

2. Remove daytime running light relay.

3. Disconnect parking lamp connector.

4. Check continuity between daytime running light relay harness connector and parking lamp harness connector.

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair or replace harness.

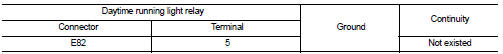

3.CHECK PARKING LAMP SHORT CIRCUIT

1. Disconnect the following connectors.

- Rear combination lamp (RH) - License plate lamp

2. Check continuity between daytime running light relay harness connector and ground.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair or replace harness.

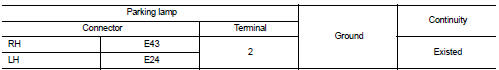

4.CHECK PARKING LAMP GROUND OPEN CIRCUIT

Check continuity between parking lamp harness connector and ground.

Is the inspection result normal? YES >> Check corresponding bulb socket and harness. Repair or replace if necessary.

NO >> Repair or replace harness.

Rear fog lamp circuit

Rear fog lamp circuit

Component Function Check

1.CHECK REAR FOG LAMP OPERATION

CONSULT-III ACTIVE TEST

1. Select “RR FOG LAMP” of BCM (HEAD LAMP) active test item.

2. With operating the test items, check that the rear ...

Tail lamp circuit

Tail lamp circuit

Without daytime running light system

WITHOUT DAYTIME RUNNING LIGHT SYSTEM : Component Function

1.CHECK TAIL LAMP OPERATION

CONSULT-III ACTIVE TEST

1. Select “EXTERNAL LAMPS” of IPDM E/R active tes ...

Other materials:

Exterior front

1. Hood

2. Windshield wiper and washer

— Switch operation

— Blade replacement

— Window washer fluid

3. Parking lights, turn signal lights and front side marker lights

— Switch operation

— Bulb replacement

4. Moonroof

5. Side turn signal lights

— Switch operation

— Bulb replaceme ...

P0075 IVT control solenoid valve

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always turn

ignition switch OFF and wait at

least 10 seconds before conducting the next test.

>> GO TO2.

2.PERFORM DTC CONFIRMATION PROCEDURE

...

Symptom diagnosis

Squeak and rattle trouble diagnoses

Work Flow

CUSTOMER INTERVIEW

Interview the customer if possible, to determine the conditions that exist

when the noise occurs. Use the Diagnostic

Worksheet during the interview to document the facts and conditions when the

noise occurs and any of

the cu ...