Nissan Juke Service and Repair Manual : P2135 TP sensor

DTC Logic

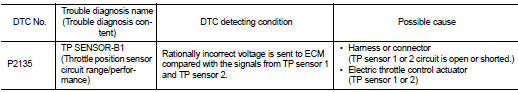

DTC DETECTION LOGIC

NOTE

:

If DTC P2135 is displayed with DTC P0643, first perform the trouble diagnosis

for DTC P0643. Refer to

EC-307, "DTC Logic".

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following procedure before conducting the next test.

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Turn ignition switch ON.

3. Turn ignition switch OFF and wait at least 10 seconds.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more

than 8 V at idle

.

>> GO TO 2.

2.PERFORM DTC CONFIRMATION PROCEDURE

1. Start engine and let it idle for 1 second.

2. Check DTC.

Is DTC detected? YES >> Proceed to EC-391, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

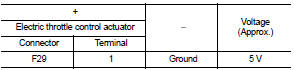

1.CHECK THROTTLE POSITION SENSOR POWER SUPPLY

1. Turn ignition switch OFF.

2. Disconnect electric throttle control actuator harness connector.

3. Turn ignition switch ON.

4. Check the voltage between electric throttle control actuator harness connector and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> GO TO 2.

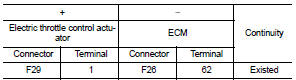

2.CHECK THROTTLE POSITION SENSOR POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

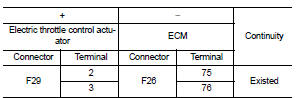

3. Check the continuity between electric throttle control actuator harness connector and ground.

4. Also check harness for short to ground.

Is the inspection result normal? YES >> Perform the trouble diagnosis for power supply circuit.

NO >> Repair or replace error-detected parts.

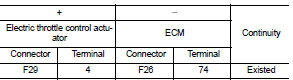

3.CHECK THROTTLE POSITION SENSOR GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check the continuity between electric throttle control actuator harness connector and ECM harness connector.

4. Also check harness for short to power.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair or replace error-detected parts.

4.CHECK THROTTLE POSITION SENSOR INPUT SIGNAL CIRCUIT

1. Check the continuity between electric throttle control actuator harness connector and ECM harness connector.

2. Also check harness for short to ground and to power.

Is the inspection result normal? YES >> GO TO 5.

NO >> Repair open circuit or short to ground or short to power in harness or connectors.

5.CHECK THROTTLE POSITION SENSOR

Check the throttle position sensor. Refer to EC-392, "Component Inspection".

Is the inspection result normal? YES >> Check intermittent incident. Refer to GI-42, "Intermittent Incident".

NO >> Replace electric throttle control actuator. Refer to EM-28, "Exploded View".

Component Inspection

1.CHECK THROTTLE POSITION SENSOR

1. Turn ignition switch OFF.

2. Reconnect all harness connectors disconnected.

3. Perform “ Throttle Valve Closed Position Learning”. Refer to EC-135, "Work Procedure".

4. Turn ignition switch ON.

5. Set selector lever to D (CVT) or 1st (M/T) position.

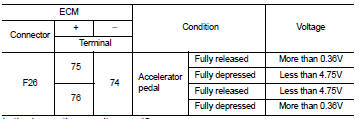

6. Check the voltage between ECM harness connector terminals as per the following conditions.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace electric throttle control actuator. Refer to EM-28, "Exploded View".

P2127, P2128 APP sensor

P2127, P2128 APP sensor

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform

the following procedure

before conductin ...

P2138 APP sensor

P2138 APP sensor

DTC Logic

DTC DETECTION LOGIC

NOTE:

If DTC P2138 is displayed with DTC P0643, first perform the trouble diagnosis

for DTC P0643. Refer to

EC-307, "DTC Logic".

DTC CONFIRMATION PROCE ...

Other materials:

Blower fan on signal

Component Function Check

1.CHECK BLOWER FAN ON SIGNAL

With CONSULT-III

1. Turn ignition switch ON.

2. Select “AIR CONDITIONER” of “BCM” using CONSULT-III.

3. Select “FAN ON SIG” in “DATA MONITOR” mode.

4. Check blower fan ON signal when the fan control dial is operated.

Is the inspection re ...

Service data and specifications (SDS)

General Specifications

MR16DDT

HR16DE, K9K

Brake Pedal

Brake Booster

2WD

4WD

Front Disc Brake

MR16DDT

HR16DE, K9K

Rear Disc Brake

...

Precaution

Precautions for Suspension

• When installing rubber bushings, the final tightening must be carried out

under unladen conditions with tires

on ground. Spilled oil might shorten the life of rubber bushings. Be sure to

wipe off any spilled oil.

- Unladen conditions mean that fuel, engine coolant ...