Nissan Juke Service and Repair Manual : P2120 APP sensor

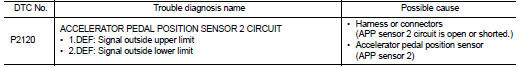

DTC Logic

DTC DETECTION LOGIC

Diagnosis Procedure

1.CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Check ground connection E38. Refer to Ground inspection in GI-44, "Circuit Inspection".

Is the inspection result normal? YES >> GO TO 2.

NO >> Repair or replace ground connection.

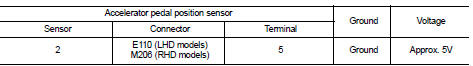

2.CHECK ACCELERATOR PEDAL POSITION SENSOR POWER SUPPLY CIRCUIT

1. Disconnect accelerator pedal position sensor harness connector.

2. Turn ignition switch ON.

3. Check the voltage between accelerator pedal position sensor connector and ground.

Is the inspection result normal? YES >> GO TO 4.

NO >> GO TO 3.

3.DETECT MALFUNCTIONING PART

• Harness connectors E105, M77 (RHD models) • Harness connectors M95, M202 (RHD models) • Harness for open or short between ECM and accelerator pedal position sensor

>> Repair open circuit or short to ground or short to power in harness or connector.

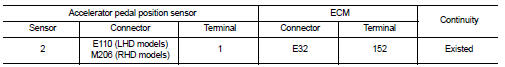

4.CHECK ACCELERATOR PEDAL POSITION SENSOR GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect accelerator pedal position sensor.

3. Check the continuity between accelerator pedal position sensor harness connector and ECM harness connector.

4. Also check harness for short to ground and short to power.

Is the inspection result normal? YES >> GO TO 6.

NO >> GO TO 5.

5.DETECT MALFUNCTIONING PART

• Harness connectors E105, M77 (RHD models) • Harness connectors M95, M202 (RHD models) • Harness for open or short between ECM and accelerator pedal position sensor

>> Repair open circuit or short to ground or short to power in harness or connector.

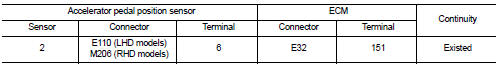

6.CHECK ACCELERATOR PEDAL POSITION SENSOR INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Check the continuity between accelerator pedal position sensor harness connector and ECM harness

2. Also check harness for short to ground and short to power.

Is the inspection result normal? YES >> GO TO 8.

NO >> GO TO 7.

7.DETECT MALFUNCTIONING PART

• Harness connectors E105, M77 (RHD models) • Harness connectors M95, M202 (RHD models) • Harness for open or short between ECM and accelerator pedal position sensor

>> Repair open circuit or short to ground or short to power in harness or connector.

8.CHECK ACCELERATOR PEDAL POSITION SENSOR

Refer to EC-1001, "Component Inspection".

Is the inspection result normal? YES >> GO TO 9.

NO >> Replace accelerator pedal position sensor.

9.CHECK INTERMITTENT INCIDENT

Refer to GI-42, "Intermittent Incident", ???INCIDENT SIMULATION TESTS??? and ???GROUND INSPECTION???.

>> INSPECTION END

Component Inspection

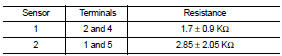

1.CHECK ACCELERATOR PEDAL POSITION SENSOR

1. Turn ignition switch OFF.

2. Disconnect accelerator pedal position sensor harness connector.

3. Check resistance between accelerator pedal position sensor as follows.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace accelerator pedal position sensor.

P2119 electric throttle control function

P2119 electric throttle control function

DTC Logic

DTC DETECTION LOGIC

Diagnosis Procedure

1.CHECK INTERMITTENT INCIDENT

Refer to GI-42, "Intermittent Incident".

Is the inspection result normal?

YES >> GO TO 2.

N ...

P2226 baro sensor

P2226 baro sensor

DTC Logic

DTC DETECTION LOGIC

Diagnosis Procedure

1.REPLACE ECM

Perform EC-879, "Work Procedure".

>> INSPECTION END ...

Other materials:

Hazard reminder operation does not operate

Diagnosis Procedure

1.CHECK DTC WITH BCM AND COMBINATION METER

Check that DTC is not detected with BCM and combination meter.

Is the inspection result normal?

YES >> GO TO 2.

NO-1 >> Refer to BCS-141, "DTC Index". (BCM)

NO-2 >> Refer to MWI-36, "DTC Index&q ...

Hazard function

Component Function Check

1.CHECK FUNCTION

1. Select “INTELLIGENT KEY” of “BCM” using CONSULT-III.

2. Select “FLASHER” in “ACTIVE TEST” mode.

3. Check that the function operates normally according to the following

conditions.

Is the inspection result normal?

YES >> Hazard warning lamp ...

Exhaust gas (carbon monoxide)

WARNING

• Do not breathe exhaust gases; they contain colorless and odorless carbon

monoxide. Carbon monoxide is dangerous. It can cause unconsciousness or death.

• If you suspect that exhaust fumes are entering the vehicle, drive with all windows

fully open, and have the vehicle inspected imme ...