Nissan Juke Service and Repair Manual : P1643 thermoplunger control unit

DTC Logic

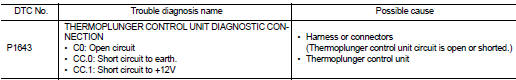

DTC DETECTION LOGIC

Diagnosis Procedure

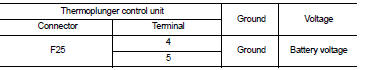

1.CHECK THERMOPLUNGER CONTROL UNIT POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect thermoplunger control unit harness connector.

3. Check the voltage between thermoplunger control unit harness connector and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> GO TO 2.

2.DETECT MALFUNCTIONING PART

Check the following.

• 100A fusible link (letter B) • Harness for open and short between thermoplunger control unit and battery

>> Repair open circuit or short to ground or short to power in harness or connectors.

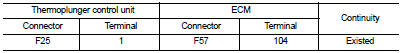

3.CHECK THERMOPLUNGER CONTROL UNIT GROUND CIRCUIT FOR OPEN AND SHORT

1. Disconnect ECM harness connector.

2. Check the continuity between thermoplunger control unit harness connector and ECM harness connector.

3. Also check harness for short to ground and short to power.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair open circuit or short to ground or short to power in harness or connectors.

4.CHECK INTERMITTENT INCIDENT

Refer to GI-42, "Intermittent Incident", ???INCIDENT SIMULATION TESTS??? and ???GROUND INSPECTION???.

Is the inspection result normal? YES >> Replace thermoplunger control unit.

NO >> Repair or replace.

P1642 thermoplunger control unit

P1642 thermoplunger control unit

DTC Logic

DTC DETECTION LOGIC

Diagnosis Procedure

1.CHECK THERMOPLUNGER CONTROL UNIT POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect thermoplunger control unit harness connector ...

P1650 thermoplunger control unit

P1650 thermoplunger control unit

DTC Logic

DTC DETECTION LOGIC

Diagnosis Procedure

1.CHECK THERMOPLUNGER CONTROL UNIT POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect thermoplunger control unit harness connector ...

Other materials:

B1081 seat belt Pre-tensioner RH

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.CHECK SELF-DIAG RESULT

With CONSULT-III

1. Turn ignition switch ON.

2. Perform “Self Diagnostic Result” mode of “AIR BAG” using CONSULT-III.

Without CONSULT-III

1. Turn ignition switch ON.

2. Check the air bag warning lamp statu ...

Speed limiter

SPEED LIMITER : Switch Name and Function

SWITCHES AND INDICATORS

NOTE:

Shared with ASCD switch.

1. Speed limiter indicator

2. SET indicator

3. Set speed indicator

4. CANCEL switch

5. RES / + switch

6. SET / − switch

7. Speed limiter MAIN Switch

8. ASCD MAIN switch

A. On the ...

Rear wiper arm

Exploded View

1. Rear wiper motor

2. Rear wiper blade

3. Rear wiper arm

4. Rear wiper arm cover

5. Rear wiper pivot seal

A : Model for cold areas

: Pawl

: N·m (kg-m, in-lb)

: N·m (kg-m, ft-lb)

Removal and Installation

REMOVAL

1. Operate rear wiper to the auto stop position.

2. Remo ...