Nissan Juke Service and Repair Manual : P1650 thermoplunger control unit

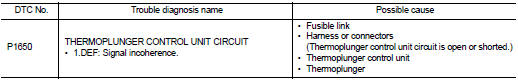

DTC Logic

DTC DETECTION LOGIC

Diagnosis Procedure

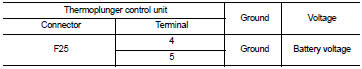

1.CHECK THERMOPLUNGER CONTROL UNIT POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect thermoplunger control unit harness connector.

3. Check the voltage between thermoplunger control unit harness connector and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> GO TO 2.

2.DETECT MALFUNCTIONING PART

Check the following.

• 100A fusible link (letter B) • Harness for open and short between thermoplunger control unit and battery

>> Repair open circuit or short to ground or short to power in harness or connectors.

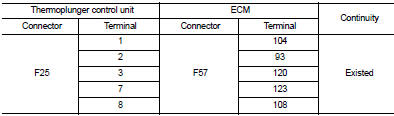

3.CHECK THERMOPLUNGER CONTROL UNIT SIGNAL CIRCUIT FOR OPEN AND SHORT-I

1. Disconnect ECM harness connector.

2. Check the continuity between thermoplunger control unit harness connector and ECM harness connector.

3. Also check harness for short to ground and short to power.

Is the inspection result normal? YES >> GO TO 5.

NO >> GO TO 4.

4.DETECT MALFUNCTIONING PART

Check the following.

• Harness for open or short between thermoplunger control unit and ECM.

>> Repair open circuit or short to ground or short to power in harness or connectors.

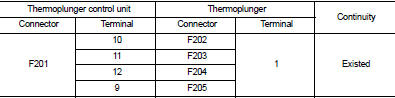

5.CHECK THERMOPLUNGER CONTROL UNIT SIGNAL CIRCUIT FOR OPEN AND SHORT-II

1. Disconnect thermoplunger harness connector.

2. Check the continuity between thermoplunger control unit harness connector and thermoplunger harness connector.

3. Also check harness for short to ground and short to power.

Is the inspection result normal? YES >> GO TO 6.

NO >> Repair open circuit or short to ground or short to power in harness or connectors.

6.CHECK THERMOPLUNGER

Refer to EC-994, "Component Inspection".

Is the inspection result normal? YES >> GO TO 7.

NO >> Replace malfunctioning Thermoplunger.

7.CHECK INTERMITTENT INCIDENT

Refer to GI-42, "Intermittent Incident".

Is the inspection result normal? YES >> Replace thermoplunger control unit.

NO >> Repair or replace.

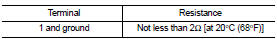

Component Inspection

1.CHECK THERMOPLUNGER

1. Turn ignition switch OFF.

2. Disconnect thermoplunger harness connector.

3. Check resistance between thermoplunger terminals as follows.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace malfunctioning thermoplunger.

P1643 thermoplunger control unit

P1643 thermoplunger control unit

DTC Logic

DTC DETECTION LOGIC

Diagnosis Procedure

1.CHECK THERMOPLUNGER CONTROL UNIT POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect thermoplunger control unit harness connector ...

P2002 diesel particulate filter

P2002 diesel particulate filter

DTC Logic

DTC DETECTION LOGIC

Diagnosis Procedure

1.CHECK DIESEL PARTICULATE FILTER

Refer to EC-995, "Component Inspection".

OK or NG

OK >> INSPECTION END

NG >> GO TO ...

Other materials:

Commercial Service Tools

CAUTION:

• Every time the vehicle is lifted up, maintain the complete vehicle curb

condition.

• Since the vehicle's center of gravity changes when removing main parts on the

front side (engine,

transmission, suspension etc.), support a jack up point on the rear side garage

jack with a mis ...

Rear bumper

Exploded View

1. Bumper side bracket LH

2. Bumper closing LH

3. Bumper fascia assembly

4. Reflex reflector LH

5. Rear panel lower

6. U nut

7. Bumper fascia lower

8. Reflex reflector RH

9. Bumper stay LH

10. screw grommet

11. Bumper energy absorber

12. Bumper stay RH

13. Bumper ...

Commercial Service Tools

HFC-134a (R-134a) Service Tool and Equipment

• Never mix HFC-134a (R-134a) refrigerant and/or its specified lubricant with

CFC-12 (R-12) refrigerant and/

or its lubricant.

• Separate and non-interchangeable service equipment must be used for handling

each type of refrigerant/

lubricant.

• R ...