Nissan Juke Service and Repair Manual : P183F gear position signal

DTC Logic

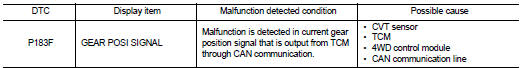

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always turn ignition switch OFF and wait at least 10 seconds before conducting the next test.

>> GO TO 2.

2.DTC REPRODUCTION PROCEDURE

With CONSULT-III

With CONSULT-III

1. Start the engine and drive at 30 km/h (19 MPH) or more for approximately 1minute.

2. Perform self-diagnosis for “ALL MODE AWD/4WD”.

Is DTC “P183F” detected? YES >> Proceed to diagnosis procedure. Refer to DLN-72, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

1.PERFORM TCM SELF-DIAGNOSIS

With CONSULT-III

With CONSULT-III

Perform self-diagnosis for “TRANSMISSION”.

Is any DTCs detected? YES >> Check the DTC. Refer to TM-171, "DTC Index".

NO >> GO TO 2.

2.ERASE SELF-DIAGNOSTIC RESULT

With CONSULT-III

With CONSULT-III

1. Erase self-diagnostic results for “ALL MODE AWD/4WD”.

2. Start the engine and drive vehicle at 30 km/h (19 MPH) or more.

3. Check that A/T CHECK indictor lamp turns OFF.

Does A/T CHECK indicator lamp turn OFF? YES >> GO TO 3.

NO >> Refer to TM-259, "Symptom Table".

3.CHECK TERMINALS AND HARNESS CONNECTORS

Check 4WD control module pin terminals for damage or loose connection with harness connector.

Is inspection result normal? YES >> After turning the ignition switch OFF, perform DTC confirmation procedure again. When DTC “P183F” is detected, Replace 4WD control module. Refer to DLN-91, "Removal and Installation".

NO >> Repair or replace error-detected parts.

P183E yaw rate sensor

P183E yaw rate sensor

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always turn

ignition switch OFF and

wait at least 10 ...

P1840 output speed signal

P1840 output speed signal

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always turn

ignition switch OFF and

wait at least 10 ...

Other materials:

Basic inspection

1.INSPECTION START

1. Check service records for any recent repairs that may indicate a related

malfunction, or a current need for

scheduled maintenance.

2. Open engine hood and check the following:

- Harness connectors for improper connections

- Wiring harness for improper connections, pinche ...

Liquid Gasket

REMOVAL OF LIQUID GASKET SEALING

• After removing mounting nuts and bolts, separate the mating surface

using the seal cutter [SST: KV10111100 (J-37228)] (A) and

remove old liquid gasket sealing.

CAUTION:

Be careful not to damage the mating surfaces.

• Tap the seal cutter [SST: KV10111100 (J- ...

Clutch pedal position switch

Component Function Check

1.CHECK CLUTCH PEDAL POSITION SWITCH FUNCTION

With CONSULT-III

1. Turn ignition switch ON.

2. Select “ENGINE” using CONSULT-III.

3. Select “CLUTCH P/P SW” in “DATA MONITOR” mode.

4. Check “CLUTCH P/P SW” indication under the following conditions.

Without CONSULT-III ...