Nissan Juke Service and Repair Manual : P1811 power supply circuit for 4wd control module

DTC Logic

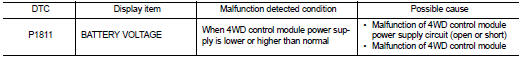

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always turn ignition switch OFF and wait at least 10 seconds before conducting the next test.

>> GO TO 2.

2.DTC REPRODUCTION PROCEDURE

With CONSULT-III

With CONSULT-III

1. Turn the ignition switch OFF to ON.

2. Perform self-diagnosis for “ALL MODE AWD/4WD”.

Is DTC “P1811” detected? YES >> Proceed to diagnosis procedure. Refer to DLN-42, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

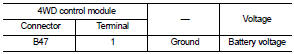

1.CHECK 4WD CONTROL MODULE POWER SUPPLY (1)

1. Turn the ignition switch OFF.

2. Disconnect 4WD control module harness connector.

3. Check the voltage between 4WD control module harness connector and ground.

4. Turn the ignition switch ON.

CAUTION:

Never start the engine.

5. Check the voltage between 4WD control module harness connector and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> GO TO 2.

2.CHECK 4WD CONTROL MODULE POWER SUPPLY (2

)

1. Turn the ignition switch OFF.

2. Check the 10A fuse (#33).

3. Check the harness for open or short between 4WD control module harness connector No.1 terminal and 10A (#33).

Is the inspection result normal?

YES >> Perform the trouble diagnosis for power supply circuit. Refer to PG-10, "Wiring Diagram - BATTERY POWER SUPPLY -".

NO >> Repair or replace error-detected parts.

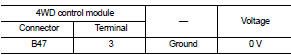

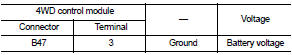

3.CHECK 4WD CONTROL MODULE POWER SUPPLY (3)

1. Turn the ignition switch OFF.

2. Check the voltage between 4WD control module harness connector and ground.

3. Turn the ignition switch ON.

CAUTION:

Never start the engine.

4. Check the voltage between 4WD control module harness connector and ground.

Is the inspection result normal? YES >> GO TO 5.

NO >> GO TO 4.

4.CHECK 4WD CONTROL MODULE POWER SUPPLY (4)

1. Turn the ignition switch OFF.

2. Check the 10A fuse (#3).

3. Check the harness for open or short between 4WD control module harness connector No.3 terminal and 10A (#3).

Is the inspection result normal? YES >> Perform the trouble diagnosis for ignition power supply circuit. Refer to PG-15, "Wiring Diagram - IGNITION POWER SUPPLY -".

NO >> Repair or replace error-detected parts.

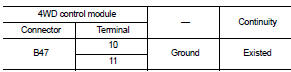

5.CHECK 4WD CONTROL MODULE GROUND

1. Turn the ignition switch OFF.

2. Check the continuity between 4WD control module harness connector and ground.

Is the inspection result normal? YES >> GO TO 6.

NO >> Repair or replace error-detected parts.

6.CHECK TERMINALS AND HARNESS CONNECTORS

Check the 4WD control module pin terminals for damage or loose connection with harness connector.

Is the inspection result normal? YES >> Replace 4WD control module. Refer to DLN-91, "Removal and Installation".

NO >> Repair or replace error-detected parts.

P1808 Wheel speed sensor

P1808 Wheel speed sensor

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always turn

ignition switch OFF and

wait at least 10 ...

P1813 4WD mode switch

P1813 4WD mode switch

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always turn

ignition switch OFF and

wait at least 10 ...

Other materials:

B2630, B2631 sunload sensor

DTC Logic

DTC DETECTION LOGIC

NOTE:

• If DTC is displayed along with DTC U1000, first perform the trouble diagnosis

for DTC U1000. Refer to HAC-

141, "DTC Logic".

• If DTC is displayed along with DTC U1010, first perform the trouble diagnosis

for DTC U1010. HAC-142,

"DTC L ...

System

Can communication system

CAN COMMUNICATION SYSTEM : System Description

CAN (Controller Area Network) is a serial communication line for real time

application. It is an on-vehicle multiplex

communication line with high data communication speed and excellent error

detection ability. Many electr ...

Hood lock

Exploded View

1. Hood lock control cable assembly

2. Hood lock assembly

: Clip

: N·m (kg-m, ft-lb)

: Body grease

Hood lock

HOOD LOCK : Removal and Installation

REMOVAL

1. Remove front center grille. Refer to EXT-18, "Removal and Installation".

2. Remove crash zone sensor. Refe ...