Nissan Juke Service and Repair Manual : P17BB primary pressure solenoid

DTC Logic

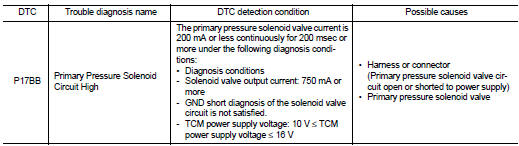

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PREPARATION BEFORE WORK

If another "DTC CONFIRMATION PROCEDURE" occurs just before, turn ignition switch OFF and wait for at least 10 seconds, then perform the next test.

>> GO TO 2.

2.CHECK DTC DETECTION

1. Start the engine and wait for 5 seconds or more.

2. Check the first trip DTC.

Is “P17BB” detected? YES >> Go to TM-459, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

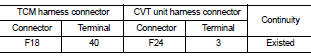

1.CHECK CIRCUIT BETWEEN TCM AND THE CVT UNIT

1. Turn ignition switch OFF.

2. Disconnect the TCM connector and the CVT unit connector.

3. Check the continuity between the TCM harness connector terminal and the CVT unit harness connector terminal.

Is the inspection result normal? YES >> GO TO 2.

NO >> Repair or replace the malfunctioning parts.

2.CHECK PRIMARY PRESSURE SOLENOID VALVE

Check the primary pressure solenoid valve. Refer to TM-460, "Component Inspection (Primary Pressure Solenoid Valve)".

Is the inspection result normal? YES >> Check intermittent incident. Refer to GI-42, "Intermittent Incident".

NO >> Repair or replace the malfunctioning parts.

Component Inspection (Primary Pressure Solenoid Valve)

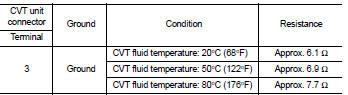

1.CHECK PRIMARY PRESSURE SOLENOID VALVE

Check the resistance between the CVT unit connector terminal and ground.

Is the inspection result normal? YES >> INSPECTION END

NO >> There is a malfunction of the primary pressure solenoid valve. Replace the transaxle assembly.

Refer to TM-508, "Removal and Installation".

P17Ba primary pressure solenoid

P17Ba primary pressure solenoid

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PREPARATION BEFORE WORK

If another "DTC CONFIRMATION PROCEDURE" occurs just before, turn ignition

switch OFF and wait for a ...

P2765 clutch B speed sensor

P2765 clutch B speed sensor

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

CAUTION:

Be careful of the driving speed.

1.PREPARATION BEFORE WORK

If another "DTC CONFIRMATION PROCEDURE" occurs just befor ...

Other materials:

Automatic speed control device (ASCD)

Automatic speed control device (ASCD)

: System Diagram

Automatic speed control device (ASCD)

: System Description

INPUT/OUTPUT SIGNAL CHART

*1: M/T models

*2: CVT models

BASIC ASCD SYSTEM

Refer to Owner's Manual for ASCD operating instructions.

Automatic Speed Control Device (ASCD) a ...

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”,

used along

with a front seat belt, helps to reduce the risk or severity of injury to the

driver and front passenger for certain

types of collision. Information necessary to service the system safely is

include ...

Battery inspection

How to Handle Battery

CAUTION:

• If it becomes necessary to start the engine with a booster battery and jumper

cables, use a 12-volt

booster battery.

• After connecting battery cables, ensure that they are tightly clamped to

battery terminals for good

contact.

• Never add distilled water t ...