Nissan Juke Service and Repair Manual : P17B8 high clutch solenoid

DTC Logic

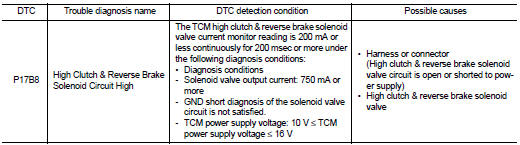

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PREPARATION BEFORE WORK

If another "DTC CONFIRMATION PROCEDURE" occurs just before, turn ignition switch OFF and wait for at least 10 seconds, then perform the next test.

>> GO TO 2.

2.CHECK DTC DETECTION

1. Start the engine and wait for 5 seconds or more 2. Check the first trip DTC.

Is “P17B8” detected? YES >> Go to TM-455, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

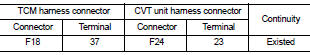

1.CHECK CIRCUIT BETWEEN TCM AND THE CVT UNIT

1. Turn ignition switch OFF.

2. Disconnect the TCM connector and the CVT unit connector.

3. Check the continuity between the TCM harness connector terminal and the CVT unit harness connector terminal.

Is the inspection result normal? YES >> GO TO 2.

NO >> Repair or replace the malfunctioning parts.

2.CHECK HIGH CLUTCH & REVERSE BRAKE SOLENOID VALVE

Check the high clutch & reverse brake solenoid valve. Refer to TM-456, "Component Inspection (High Clutch & Reverse Brake Solenoid Valve)".

Is the inspection result normal? YES >> Check intermittent incident. Refer to GI-42, "Intermittent Incident".

NO >> Repair or replace the malfunctioning parts.

Component Inspection (High Clutch & Reverse Brake Solenoid Valve)

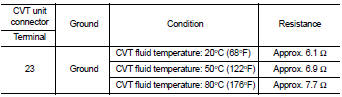

1.CHECK HIGH CLUTCH & REVERSE BRAKE SOLENOID VALVE

Check the resistance between the CVT unit connector terminal and ground.

Is the inspection result normal? YES >> INSPECTION END

NO >> There is a malfunction of the high & reverse brake solenoid valve. Replace the transaxle assembly.

Refer to TM-508, "Removal and Installation".

P17B7 high clutch solenoid

P17B7 high clutch solenoid

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PREPARATION BEFORE WORK

If another "DTC CONFIRMATION PROCEDURE" occurs just before, turn ignition

switch OFF and wait for a ...

P17Ba primary pressure solenoid

P17Ba primary pressure solenoid

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PREPARATION BEFORE WORK

If another "DTC CONFIRMATION PROCEDURE" occurs just before, turn ignition

switch OFF and wait for a ...

Other materials:

Oil cooler

Exploded View

1. Cylinder block

2. Water pipe

3. O-ring

4. O-ring

5. O-ring

6. Oil cooler

7. Connecting stud

8. O-ring

9. Oil filter bracket

10. Oil pressure switch

11. Oil filter

12. O-ring

13. Connecting bolt

A. : To radiator lower hose

B. : To water pump

: N·m (kg-m, ft- ...

P060B ECM

DTC Logic

DTC DETECTION LOGIC

Diagnosis Procedure

1.INSPECTION START

1. Turn ignition switch ON.

2. Erase DTC.

3. Turn ignition switch OFF and wait for 20 seconds.

4. Turn ignition switch ON and perform the self-diagnosis.

Is the DTC P060B displayed again?

YES >> GO TO 2.

NO &g ...

U0415 vehicle speed

Description

U0415 is displayed if any unusual condition is present in the reception

status of the vehicle speed signal from

the ABS actuator and electric unit (control unit).

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.DTC CONFIRMATION

1. Erase the DTC.

2. Turn ignition sw ...