Nissan Juke Service and Repair Manual : P1556, P1557 battery temperature sensor

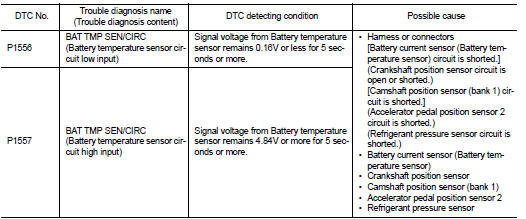

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Turn ignition switch ON.

3. Turn ignition switch OFF and wait at least 10 seconds.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is 10 V

or more at idle.

>> GO TO 2.

2.PERFORM DTC CONFIRMATION PROCEDURE

1. Start the engine and let it idle at least 10 seconds.

2. Check 1st trip DTC.

Is 1st trip DTC detected? YES >> Proceed to EC-712, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

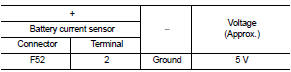

1.CHECK BATTERY TEMPERATURE SENSOR POWER SUPPLY

1. Turn ignition switch OFF.

2. Disconnect battery current sensor harness connector.

3. Turn ignition switch ON.

4. Check the voltage between battery current sensor harness connector and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> GO TO 2.

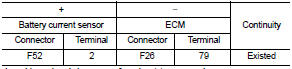

2.CHECK BATTERY TEMPERATURE SENSOR POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check the continuity between battery current sensor harness connector and ECM harness connector.

4. Also check harness for short to ground.

Is the inspection result normal? YES >> Perform the trouble diagnosis for power supply circuit.

NO >> Repair or replace error-detected parts.

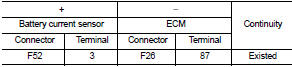

3.CHECK BATTERY TEMPERATURE SENSOR GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check the continuity between battery current sensor harness connector and ECM harness connector.

4. Also check harness for short to power.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair or replace error-detected parts.

4.CHECK BATTERY TEMPERATURE SENSOR

Check the battery temperature sensor. Refer to EC-713, "Component Inspection".

Is the inspection result normal? YES >> Check intermittent incident. Refer to GI-42, "Intermittent Incident".

NO >> Replace battery negative cable assembly. Refer to PG-125, "Exploded View".

Component Inspection

1.CHECK BATTERY TEMPERATURE SENSOR

1. Turn ignition switch OFF.

2. Disconnect battery current sensor.

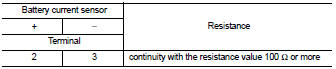

3. Check the resistance between battery current sensor connector terminals.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace battery negative cable assembly. Refer to PG-125, "Exploded View".

P1554 battery current sensor

P1554 battery current sensor

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PERFORM COMPONENT FUNCTION CHECK

Perform component function check. Refer to EC-709, "Component Function

Check".

NOTE:

U ...

P1564 ASCD steering switch

P1564 ASCD steering switch

DTC Logic

DTC DETECTION LOGIC

NOTE:

If DTC P1564 is displayed with DTC P0605, first perform the trouble diagnosis

for DTC P0605. Refer to

EC-683, "DTC Logic".

DTC CONFIRMATION PROCE ...

Other materials:

Power supply and ground circuit

AUDIO UNIT

AUDIO UNIT : Diagnosis Procedure

1.CHECK FUSE

Check for blown fuses.

Is inspection result OK?

YES >> GO TO 2.

NO >> Be sure to eliminate cause of malfunction before installing new fuse.

2.CHECK POWER SUPPLY CIRCUIT

Check voltage between audio unit harness connect ...

P2138 APP sensor

DTC Logic

DTC DETECTION LOGIC

NOTE:

If DTC P2138 is displayed with DTC P0643, first perform the trouble diagnosis

for DTC P0643. Refer to

EC-307, "DTC Logic".

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform ...

Headlining

Exploded View

LHD models

1. Headlining assembly

2. Assist grip clip

3. Rear assist grip RH

4. Front assist grip RH

5. Sun visor assembly RH

6. Sun visor cover RH

7. Sun visor cover LH

8. Sun visor assembly LH

9. Rear assist grip LH

10. Headlining clip

11. Sun visor holder RH

1 ...