Nissan Juke Service and Repair Manual : P1078 EVT control position sensor

DTC Logic

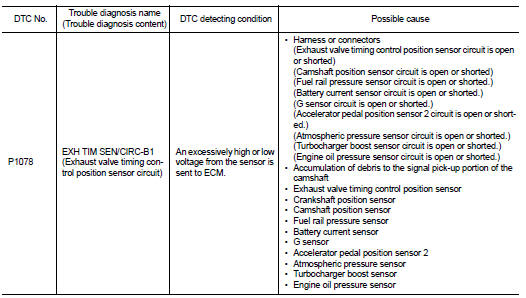

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following procedure before conducting the next test.

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Turn ignition switch ON.

3. Turn ignition switch OFF and wait at least 10 seconds.

>> GO TO 2.

2.PERFORM DTC CONFIRMATION PROCEDURE

1. Start engine and let it idle for 10 seconds.

2. Check 1st trip DTC.

Is 1st trip DTC detected? YES >> Proceed to EC-313, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

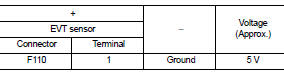

1.CHECK EXHAUST VALVE TIMING (EVT) CONTROL POSITION SENSOR POWER SUPPLY

1. Turn ignition switch OFF.

2. Disconnect exhaust valve timing (EVT) control position sensor harness connector.

3. Turn ignition switch ON.

4. Check the voltage between EVT control position sensor harness connector and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> GO TO 2.

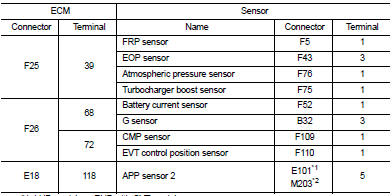

2.CHECK SENSOR POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check harness connector for short to power and short to ground, between the following terminals.

*1: LHD models or RHD with CVT models *2: RHD with M/T models

Is inspection result normal? YES >> Perform the trouble diagnosis for power supply circuit.

NO >> Repair or replace error-detected parts.

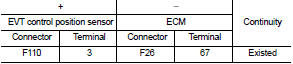

3.CHECK EVT CONTROL POSITION SENSOR GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check the continuity between EVT control position sensor harness connector and ECM harness connector.

4. Also check harness for short to power.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair or replace error-detected parts.

4.CHECK EVT CONTROL POSITION SENSOR INPUT SIGNAL CIRCUIT

1. Disconnect ECM harness connector.

2. Check the continuity between EVT control position sensor harness connector and ECM harness connector.

3. Also check harness for short to ground and to power.

Is the inspection result normal? YES >> GO TO 5.

NO >> Repair or replace error-detected parts.

5.CHECK EVT CONTROL POSITION SENSOR

Check the EVT control position sensor. Refer to EC-315, "Component Inspection".

Is the inspection result normal? YES >> GO TO 6.

NO >> Replace EVT control position sensor. Refer to EM-79, "Removal and Installation".

6.CHECK CAMSHAFT (EXT)

Check the following.

• Accumulation of debris to the signal plate of camshaft rear end • Chipping signal plate of camshaft rear end

s the inspection result normal? YES >> Check intermittent incident. Refer to GI-42, "Intermittent Incident".

NO >> Remove debris and clean the signal plate of camshaft rear end or replace camshaft. Refer to EM-79, "Removal and Installation".

Component Inspection

1.EXHAUST VALVE TIMING (EVT) CONTROL POSITION SENSOR-I

1. Turn ignition switch OFF.

2. Disconnect EVT control position sensor harness connector.

3. Loosen the fixing bolt of the sensor.

4. Remove the sensor.

5. Visually check the sensor for chipping.

Is the inspection result normal? YES >> GO TO 2.

NO >> Replace EVT control position sensor. Refer to EM-67, "Exploded View".

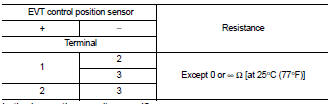

2.EVT CONTROL POSITION SENSOR-II

Check resistance EVT control position sensor terminals as shown below.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace EVT control position sensor. Refer to EM-67, "Exploded View".

P0850 PNP switch

P0850 PNP switch

Description

For CVT models, transmission range switch is turn ON when the selector lever

is P or N.

For M/T models, park/neutral position (PNP) range switch is ON when the selector

lever is Ne ...

P1197 out of gas

P1197 out of gas

Description

This diagnosis result is detected when the fuel level of the fuel tank is

extremely low and the engine does not

run normally.

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCED ...

Other materials:

Cleaning interior

Occasionally remove loose dust from the interior trim, plastic parts and seats

using a vacuum cleaner or soft bristled brush. Wipe the vinyl and leather surfaces

with a clean, soft cloth dampened in mild soap solution, then wipe clean with a

dry soft cloth.

Regular care and cleaning is requir ...

Structure and operation

Sectional View

1. Transfer cover

2. Ring gear shaft

3. Companion flange

4. Drive pinion

5. Ring gear

6. Transfer case

Operation Principle

POWER TRANSFER DIAGRAM

1. Engine

2. Transaxle

3. Transfer

4. Propeller shaft

5. Electric controlled coupling

6. Rear final drive

ELECTR ...

U1000 can comm circuit

Description

CAN (Controller Area Network) is a serial communication line for real time

application. It is an on-vehicle multiplex

communication line with high data communication speed and excellent error

detection ability. Many electronic

control units are equipped onto a vehicle, and each co ...