Nissan Juke Service and Repair Manual : P0705 transmission range switch A

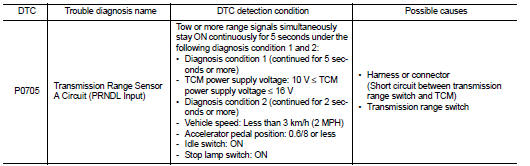

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

CAUTION:

Be careful of the driving speed

.

1.PREPARATION BEFORE WORK

If another "DTC CONFIRMATION PROCEDURE" occurs just before, turn ignition switch OFF and wait for at least 10 seconds, then perform the next test.

>> GO TO 2.

2.CHECK DTC DETECTION

1. Start the engine.

2. Maintain the following conditions.

Accelerator pedal position : 0.0/8

Brake pedal : Depressed

Vehicle speed : 0 km/h (0 MPH)

3. Shift the selector lever through entire positions from “P” to “L”. (Hold

the selector lever at each position for

10 seconds or more.)

4. Check the first trip DTC.

Is “P0705” detected? YES >> Go to TM-394, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

1.CHECK TCM INPUT SIGNALS

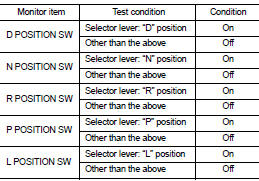

With CONSULT-III

With CONSULT-III

1. Turn ignition switch ON.

2. Select “Data Monitor” in “TRANSMISSION”.

3. Select “D POSITION SW”, “N POSITION SW”, “R POSITION SW”, “P POSITION SW” and “L POSITION SW”.

4. Shift the selector lever through entire positions from “P” to “L” and check ON/OFF of each monitor item.

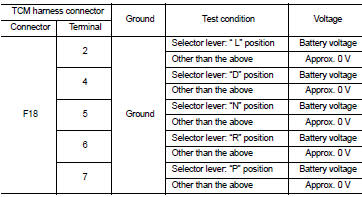

Without CONSULT-III.

Without CONSULT-III.

1. Turn the ignition switch OFF.

2. Disconnect the TCM connector.

3. Turn ignition switch ON.

4. Shift the selector lever from “P” to “L” and check the voltage between the TCM harness connector terminal and the ground.

Is the check result normal? YES >> Check intermittent incident. Refer to GI-42, "Intermittent Incident".

NO-1 [“D POSITION SW” is “ON” when selector is not in “D” position. (Or connector terminal 4 is at power voltage.)]>>GO TO 2.

NO-2 [“N POSITION SW” is “ON” when selector is not in “N” position. (Or connector terminal 5 is at power voltage.)]>>GO TO 4.

NO-3 [“R POSITION SW” is “ON” when selector is not in “R” position. (Or connector terminal 6 is at power voltage.)]>>GO TO 6.

NO-4 [“P POSITION SW” is “ON” when selector is not in “P” position. (Or connector terminal 7 is at power voltage.)]>>GO TO 8.

NO-5 [“L POSITION SW” is “ON” when selector is not in “L” position. (Or connector terminal 2 is at power voltage.)]>>GO TO 10.

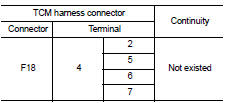

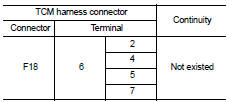

2.CHECK D POSITION SW CIRCUIT (PART 1)

1. Turn the ignition switch OFF.

2. Disconnect the TCM connector.

3. Check the continuity between the TCM harness connector terminals.

Is the check result normal? YES >> GO TO 3.

NO >> Repair or replace the malfunctioning parts.

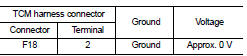

3.CHECK D POSITION SW CIRCUIT (PART 2)

1. Disconnect the transmission position switch connector.

2. Turn ignition switch ON.

3. Check the voltage between the TCM harness connector and ground.

Is the check result normal? YES >> GO TO 12.

NO >> Repair or replace the malfunctioning parts.

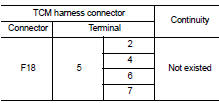

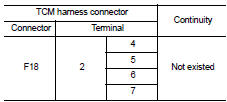

4.CHECK N POSITION SW CIRCUIT (PART 1)

1. Turn the ignition switch OFF.

2. Disconnect the TCM connector.

3. Check the continuity between the TCM harness connector terminals.

Is the check result normal? YES >> GO TO 5.

NO >> Repair or replace the malfunctioning parts.

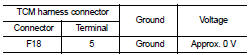

5.CHECK N POSITION SW CIRCUIT (PART 2)

1. Disconnect the transmission position switch connector.

2. Turn ignition switch ON.

3. Check the voltage between the TCM harness connector and ground.

Is the check result normal? YES >> GO TO 12.

NO >> Repair or replace the malfunctioning parts.

6.CHECK P POSITION SW CIRCUIT (PART 1)

1. Turn the ignition switch OFF.

2. Disconnect the TCM connector.

3. Check the continuity between the TCM harness connector terminals.

Is the check result normal? YES >> GO TO 7.

NO >> Repair or replace the malfunctioning parts.

7.CHECK P POSITION SW CIRCUIT (PART 2)

1. Disconnect the transmission position switch connector.

2. Turn ignition switch ON.

3. Check the voltage between the TCM harness connector and ground.

Is the check result normal? YES >> GO TO 12.

NO >> Repair or replace the malfunctioning parts.

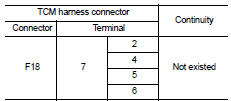

8.CHECK R POSITION SW CIRCUIT (PART1)

1. Turn the ignition switch OFF.

2. Disconnect the TCM connector.

3. Check the continuity between the TCM harness connector terminals

Is the check result normal? YES >> GO TO 9.

NO >> Repair or replace the malfunctioning parts.

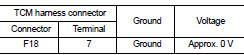

9.CHECK R POSITION SW CIRCUIT (PART 2)

1. Disconnect the transmission position switch connector.

2. Turn ignition switch ON.

3. Check the voltage between the TCM harness connector and ground.

Is the check result normal? YES >> GO TO 12.

NO >> Repair or replace the malfunctioning parts.

10.CHECK 1: L POSITION SWITCH CIRCUIT (PART 1)

1. Turn the ignition switch OFF.

2. Disconnect the TCM connector.

3. Check the continuity between the TCM harness connector terminals.

Is the check result normal? YES >> GO TO 11.

NO >> Repair or replace the malfunctioning parts.

11.CHECK 2: L POSITION SWITCH CIRCUIT (PART 2)

1. Disconnect the transmission position switch connector.

2. Turn ignition switch ON.

3. Check the voltage between the TCM harness connector and ground.

Is the check result normal? YES >> GO TO 12.

NO >> Repair or replace the malfunctioning parts.

12.CHECK TRANSMISSION RANGE SWITCH

Check the transmission range switch. Refer to TM-398, "Component Inspection (Transmission Range Switch)".

Is the check result normal? YES >> Check intermittent incident. Refer to GI-42, "Intermittent Incident".

NO >> Repair or replace the malfunctioning parts.

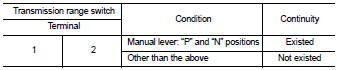

Component Inspection (Transmission Range Switch)

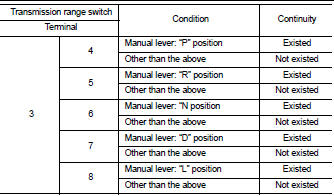

1.CHECK TRANSMISSION RANGE SWITCH

Check the continuity between the transmission range switch connector terminals.

Is the inspection result normal? YES >> INSPECTION END

NO >> There is a malfunction of the transmission range switch. Replace the transaxle assembly. Refer to TM-508, "Removal and Installation".

P062f eeprom

P062f eeprom

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PREPARATION BEFORE WORK

If another "DTC CONFIRMATION PROCEDURE" occurs just before, turn ignition

switch OFF and wait for a ...

P0706 transmission range sensor A

P0706 transmission range sensor A

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PREPARATION BEFORE WORK

If another "DTC CONFIRMATION PROCEDURE" occurs just before, turn ignition

switch OFF and wait for a ...

Other materials:

Excessive operation frequency

Description

ESP function, TCS function, ABS function, EBD function and brake limited slip

differential (BLSD) function

operates in excessive operation frequency.

Diagnosis Procedure

1.CHECK BRAKING FORCE

Check brake force using a brake tester.

Is the inspection result normal?

YES >> ...

Intelligent Key operating range

The Intelligent Key functions can only be used when the Intelligent Key is within

the specified operating range from the request switch 1 .

When the Intelligent Key battery is discharged or strong radio waves are present

near the operating location, the Intelligent Key system’s operating rang ...

Checking engine oil level

1. Park the vehicle on a level surface and apply the parking brake.

2. Run the engine until it reaches operating temperature.

3. Turn off the engine. Wait more than 10 minutes for the oil to drain back into

the oil pan.

4. Remove the dipstick and wipe it clean.

Reinsert it all the way.

5. R ...