Nissan Juke Service and Repair Manual : P0638 electric throttle control actuator function

DTC Logic

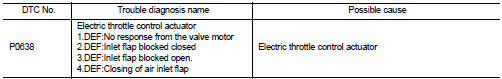

DTC DETECTION LOGIC

NOTE

:

If DTC P0638 is displayed with DTC P0120 or P2100, first perform trouble

diagnosis for DTC P0120 or P2100.

Refer to EC-909, "DTC Logic" (P0120), EC-997, "DTC Logic" (P2100).

Diagnosis Procedure

1.CHECK ELECTRIC THROTTLE CONTROL ACTUATOR

Perform EC-910, "Component Inspection" (P0120), EC-998, "Component Inspection" (P2100).

Is the inspection result normal? YES >> GO TO 3.

NO >> GO TO 2.

2.REPLACE ELECTRIC THROTTLE CONTROL ACTUATOR

1. Replace electric throttle control actuator.

2. Perform EC-973, "Special Repair Requirement".

>> INSPECTION END

3.CHECK INTERMITTENT INCIDENT

Refer to GI-42, "Intermittent Incident".

>> INSPECTION END

Special Repair Requirement

1.PERFORM THROTTLE VALVE CLOSED POSITION LEARNING

Refer to EC-882, "Work Procedure".

>> END

P062B ECM

P062B ECM

DTC Logic

DTC DETECTION LOGIC

Diagnosis Procedure

1.INSPECTION START

1. Turn ignition switch ON.

2. Erase DTC.

3. Turn ignition switch OFF and wait for 20 seconds.

4. Turn ignition switch ON ...

P0641 sensor power supply

P0641 sensor power supply

DTC Logic

DTC DETECTION LOGIC

Diagnosis Procedure

1.CHECK GROUND CONNECTION

1. Turn ignition switch OFF.

2. Check ground connection E38. Refer to Ground Inspection in GI-44, "Circuit

Ins ...

Other materials:

Squeak and rattle trouble diagnoses

Work Flow

CUSTOMER INTERVIEW

Interview the customer if possible, to determine the conditions that exist

when the noise occurs. Use the Diagnostic

Worksheet during the interview to document the facts and conditions when the

noise occurs and any of

customer's comments; refer to DLK-302, &quo ...

System

NISSAN dynamic control system

NISSAN DYNAMIC CONTROL SYSTEM : System Description

SYSTEM DIAGRAM

• *1: M/T models except for K9K engine models

• *2: CVT models

MULTI DISPLAY UNIT INPUT/OUTPUT SINGNAL

Output signal

SYSTEM DESCRIPTION

• The multi display unit receives necessary informatio ...

Unit removal and installation

Engine assembly

Exploded View

1. Engine mounting assembly (RH)

2. Rear engine mounting bracket

3. Rear torque rod

4. Engine mounting bracket (LH)

5. Stud bolt

6. Engine mounting bracket (LH)

7. Engine mounting insulator (LH)

8. Mass damper

: N·m (kg-m, ft-lb)

CAUTION:

Check that ...