Nissan Juke Service and Repair Manual : P0520 EOP sensor

DTC Logic

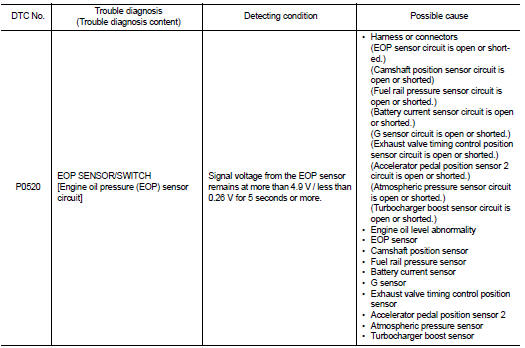

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following procedure before conducting the next test.

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Turn ignition switch ON.

3. Turn ignition switch OFF and wait at least 10 seconds.

>> GO TO 2.

2.PERFORM DTC CONFIRMATION PROCEDURE

1. Turn ignition switch ON and wait at least 5 seconds.

2. Check 1st trip DTC.

Is 1st trip DTC detected? YES >> Proceed to EC-674, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

1.CHECK ENGINE OIL

1. Turn ignition switch OFF.

2. Check engine oil level and pressure. Refer to LU-8, "Inspection".

Is inspection result normal? YES >> GO TO 2.

NO >> Repair or replace error-detected parts.

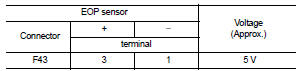

2.CHECK EOP SENSOR POWER SUPPLY-I

1. Disconnect EOP sensor connector.

2. Turn ignition switch ON.

3. Check the voltage between EOP sensor harness connector terminals.

Inspection result normal? YES >> GO TO 7.

NO >> GO TO 3.

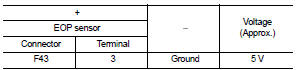

3.CHECK EOP SENSOR POWER SUPPLY-II

Check the voltage between EOP sensor harness connector and the ground.

Is inspection result normal? YES >> GO TO 5.

NO >> GO TO 4.

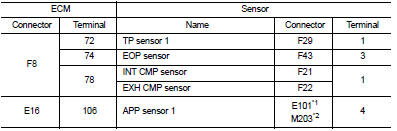

4.CHECK SENSOR POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check harness connector for short to power and short to ground, between the following terminals

*1: LHD models or RHD with CVT models *2: RHD with M/T models

Is inspection result normal? YES >> Perform the trouble diagnosis for power supply circuit.

NO >> Repair or replace error-detected parts.

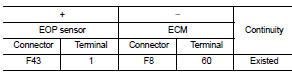

5.CHECK EOP SENSOR GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check the continuity between EOP sensor harness connector and ECM harness connector.

4. Also check harness for short to power.

Is inspection result normal? YES >> GO TO 6.

NO >> Repair or replace error-detected parts.

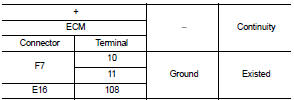

6.CHECK ECM GROUND CIRCUIT

Check the continuity between ECM harness connector and ground.

Is inspection result normal? YES >> Check intermittent incident. Refer to GI-42, "Intermittent Incident".

NO >> Repair or replace error-detected parts.

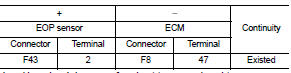

7.CHECK EOP SENSOR SIGNAL CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check the continuity between EOP sensor harness connector and ECM harness connector.

4. Also check harness for short to ground and to power.

Is inspection result normal? YES >> GO TO 8.

NO >> Repair or replace error-detected parts.

8.CHECK EOP SENSOR

Refer to EC-676, "Component Inspection".

Is inspection result normal? YES >> Check intermittent incident. Refer to GI-42, "Intermittent Incident".

NO >> Repair or replace error-detected parts.

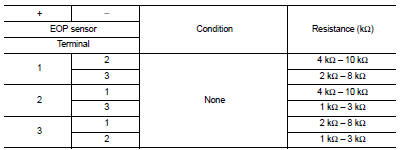

Component Inspection

1.CHECK EOP SENSOR

1. Turn ignition switch OFF.

2. Disconnect EOP sensor harness connector.

3. Check resistance between EOP sensor connector terminals.

Is the inspection result normal? YES >> INSPECTION END.

NO >> Replace EOP sensor. Refer to EM-103, "Exploded View".

P0500 VSS

P0500 VSS

Description

The vehicle speed signal is sent to the combination meter from the “ABS

actuator and electric unit (control

unit)” by CAN communication line. The combination meter then sends a signal ...

P0524 engine oil pressure

P0524 engine oil pressure

DTC Logic

DTC DETECTION LOGIC

NOTE:

If DTC P0524 is displayed with DTC P0520 or P0075, perform trouble diagnosis for

DTC P0520 or P0075

first. Refer to EC-674, "DTC Logic" or EC-583, & ...

Other materials:

Seats

WARNING

• Do not ride in a moving vehicle when the seatback is reclined. This can

be dangerous. The shoulder belt will not be against your body. In an accident, you

could be thrown into it and receive neck or other serious injuries. You could also

slide under the lap belt and receive seriou ...

Brake booster

Exploded View

2WD

MR16DDT, HR16DE

1. Master cylinder assembly

2. Vacuum pipe

3. Brake booster

4. Lock nut

5. Clevis

6. Gasket

: N·m (kg-m, ft-lb)

K9K

1. Master cylinder assembly

2. Vacuum pipe

3. Brake booster

4. Lock nut

5. Clevis

6. Gasket

: N·m (kg-m, ft-lb)

4WD

1 ...

Erratic acceleration

Description

CHART 10: Erratic acceleration

Diagnosis Procedure

1.CHECK ECM POWER SUPPLY AND GROUND CIRCUIT

Check ECM power supply and ground circuit. Refer to EC-885, "Diagnosis

Procedure".

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair or replace ha ...