Nissan Juke Service and Repair Manual : P0180 FPT sensor

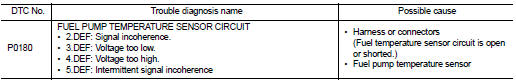

DTC Logic

DTC DETECTION LOGIC

Diagnosis Procedure

1.CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Check ground connection E38. Refer to Ground inspection in GI-44, "Circuit Inspection".

Is the inspection result normal? YES >> GO TO 2.

NO >> Repair or replace ground connection.

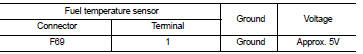

2.CHECK FUEL TEMPERATURE SENSOR SUPPLY CIRCUIT

1. Disconnect fuel temperature sensor harness connector.

2. Turn ignition switch ON.

3. Check the voltage between fuel temperature sensor connector and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair open circuit or short to ground or short to power in harness or connectors.

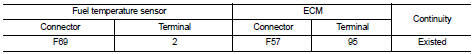

3.CHECK FUEL TEMPERATURE SENSOR GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check the continuity between fuel temperature sensor harness connector and ECM harness connector.

4. Also check harness for short to ground and short to power.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair open circuit or short to ground or short to power in harness or connectors.

4.CHECK FUEL TEMPERATURE SENSOR

Refer to EC-916, "Component Inspection".

Is the inspection result normal? YES >> GO TO 5.

NO >> Replace fuel temperature sensor.

5.CHECK INTERMITTENT INCIDENT

Refer to GI-42, "Intermittent Incident", ???INCIDENT SIMULATION TESTS??? and ???GROUND INSPECTION???.

>> INSPECTION END

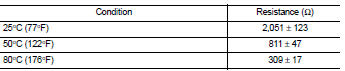

Component Inspection

1.CHECK FUEL TEMPERATURE SENSOR

Check resistance between fuel temperature sensor terminals 1 and 2 under the following conditions.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace fuel temperature sensor.

P012B TC boost sensor

P012B TC boost sensor

DTC Logic

DTC DETECTION LOGIC

Diagnosis Procedure

1.CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Check ground connection E38. Refer to Ground inspection in GI-44, "Circuit

In ...

P0190 FRP sensor

P0190 FRP sensor

DTC Logic

DTC DETECTION LOGIC

Diagnosis Procedure

1.CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Check ground connection E38. Refer to Ground inspection in GI-44, "Circuit

In ...

Other materials:

B1089 seat belt Pre-tensioner LH

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.CHECK SELF-DIAG RESULT

With CONSULT-III

1. Turn ignition switch ON.

2. Perform “Self Diagnostic Result” mode of “AIR BAG” using CONSULT-III.

Without CONSULT-III

1. Turn ignition switch ON.

2. Check the air bag warning lamp statu ...

Refilling

1. Remove filler plug (1) and gasket from transaxle case.

2. Fill with new gear oil until oil level reaches the specified limit at

filler plug mounting hole as shown in the figure.

Oil grade and

viscosity

: Refer to MA-13, "Fluids and Lubricants".

Oil capacity : Refer to TM-63, " ...

Inspection

INSPECTION AFTER INSTALLATION

• Check accelerator pedal moves smoothly within the whole operation range

when it is fully depressed and

released.

• Check accelerator pedal securely returns to the fully released position.

• For the electrical inspection of accelerator pedal position sensor. Refe ...