Nissan Juke Service and Repair Manual : P0120 TP sensor

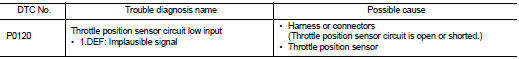

DTC Logic

DTC DETECTION LOGIC

Diagnosis Procedure

1.CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF and wait at least 20 seconds.

2. Check ground connection E38. Refer to Ground inspection in GI-44, "Circuit Inspection".

Is the inspection result normal? YES >> GO TO 2.

NO >> Repair or replace ground connection.

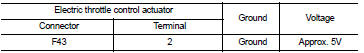

2.CHECK THROTTLE POSITION SENSOR POWER SUPPLY CIRCUIT

1. Disconnect electric throttle control actuator harness connector.

2. Turn ignition switch ON.

3. Check the voltage between electric throttle control actuator harness connector and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair open circuit or short to ground or short to power in harness or connectors.

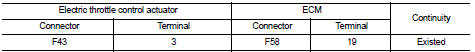

3.CHECK THROTTLE POSITION SENSOR GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF and wait at least 20 seconds.

2. Disconnect ECM harness connector.

3. Check the continuity between electric throttle control actuator harness connector and ECM harness connector.

4. Also check harness for short to ground and short to power.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair open circuit or short to ground or short to power in harness or connectors.

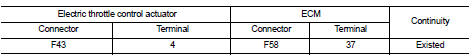

4.CHECK THROTTLE POSITION SENSOR INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Check the continuity between electric throttle control actuator harness connector and ECM harness connector.

2. Also check harness for short to ground and short to power.

Is the inspection result normal? YES >> GO TO 5.

NO >> Repair open circuit or short to ground or short to power in harness or connectors.

5.CHECK THROTTLE POSITION SENSOR

Refer to EC-910, "Component Inspection".

Is the inspection result normal? YES >> GO TO 7.

NO >> GO TO 6.

6.REPLACE ELECTRIC THROTTLE CONTROL ACTUATOR

1. Replace electric throttle control actuator.

2. Perform EC-910, "Special Repair Requirement".

>> INSPECTION END

7.CHECK INTERMITTENT INCIDENT

Refer to GI-42, "Intermittent Incident".

>> INSPECTION END

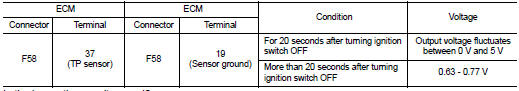

Component Inspection

1.CHECK THROTTLE POSITION SENSOR

1. Turn ignition switch OFF.

2. Reconnect all harness connectors disconnected.

3. Turn ignition switch ON.

4. Check the voltage between ECM harness connector terminals as follows.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace electric throttle control actuator assembly.

Special Repair Requirement

1.PERFORM THROTTLE VALVE CLOSED POSITION LEARNING

Refer to EC-882, "Work Procedure".

>> END

P0115 ECT sensor

P0115 ECT sensor

DTC Logic

DTC DETECTION LOGIC

Diagnosis Procedure

1.CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Check ground connection E38. Refer to Ground inspection in GI-44, "Circuit

In ...

P012A TC boost sensor

P012A TC boost sensor

DTC Logic

DTC DETECTION LOGIC

Diagnosis Procedure

1.CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Check ground connection E38. Refer to Ground inspection in GI-44, "Circuit

In ...

Other materials:

Keyfob

Replace the battery in the keyfob as follows:

1. Remove the screw.

2. Insert a small screwdriver into the slit of the corner and twist it to separate

the upper part from the lower part. Use a cloth to protect the casing.

3. Replace the battery with a new one.

Recommended battery:

CR1620 or eq ...

P0011 IVT control

DTC Logic

DTC DETECTION LOGIC

NOTE:

If DTC P0011 is displayed with DTC P0075, first perform the trouble diagnosis

for EC-307, "DTC Logic".

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform

the following proc ...

Diagnosis systeM (BCM) (without intelligent key system)

Common item

COMMON ITEM : CONSULT-III Function (BCM - COMMON ITEM)

APPLICATION ITEM

CONSULT-III performs the following functions via CAN communication with BCM.

SYSTEM APPLICATION

BCM can perform the following functions for each system.

NOTE:

It can perform the diagnosis modes except the ...