Nissan Juke Service and Repair Manual : P0115 ECT sensor

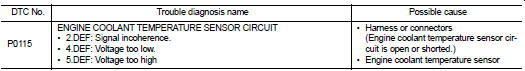

DTC Logic

DTC DETECTION LOGIC

Diagnosis Procedure

1.CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Check ground connection E38. Refer to Ground inspection in GI-44, "Circuit Inspection".

Is the inspection result normal? YES >> GO TO 2.

NO >> Repair or replace ground connection.

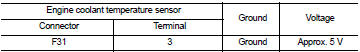

2.CHECK ENGINE COOLANT TEMPERATURE SENSOR SUPPLY CIRCUIT

1. Disconnect engine coolant temperature sensor harness connector.

2. Turn ignition switch ON.

3. Check the voltage between engine coolant temperature sensor connector and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair open circuit or short to ground or short to power in harness or connectors.

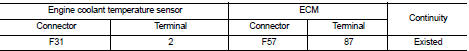

3.CHECK ENGINE COOLANT TEMPERATURE SENSOR GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check the continuity between engine coolant temperature sensor harness connector and ECM harness connector.

4. Also check harness for short to ground and short to power.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair open circuit or short to ground or short to power in harness or connectors.

4.CHECK ENGINE COOLANT TEMPERATURE SENSOR

Refer to EC-908, "Component Inspection".

Is the inspection result normal? YES >> GO TO 5.

NO >> Replace engine coolant temperature sensor.

5.CHECK INTERMITTENT INCIDENT

Refer to GI-42, "Intermittent Incident", ???INCIDENT SIMULATION TESTS??? and ???GROUND INSPECTION???.

>> INSPECTION END

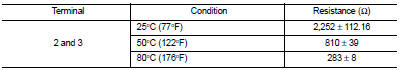

Component Inspection

1.CHECK ENGINE COOLANT TEMPERATURE SENSOR

Check resistance between engine coolant temperature sensor terminals 2 and 3 under the following conditions.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace Engine coolant temperature sensor.

P0110 IAT sensor

P0110 IAT sensor

DTC Logic

DTC DETECTION LOGIC

Diagnosis Procedure

1.CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Check ground connection E38. Refer to Ground inspection in GI-44, "Circuit

In ...

P0120 TP sensor

P0120 TP sensor

DTC Logic

DTC DETECTION LOGIC

Diagnosis Procedure

1.CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF and wait at least 20 seconds.

2. Check ground connection E38. Refer to Ground inspection ...

Other materials:

Wiring diagram

AUTOMATIC AIR CONDITIONING SYSTEM

Wiring Diagram

For connector terminal arrangements, harness layouts, and alphabets in a

(option abbreviation; if not

described in wiring diagram), refer to GI-12, "Connector Information/Explanation

of Option Abbreviation".

...

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TENSIONER"

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”,

used along

with a front seat belt, helps to reduce the risk or severity of injury to the

driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage

f ...

Component parts

Component Parts Location

LHD

2WD

1. ECM

Refer to EC-25, "ENGINE CONTROL

SYSTEM :

Component Parts Location"

(MR16DDT), EC-455, "ENGINE

CONTROL SYSTEM :

Component Parts Location"

(HR16DE), EC-813, "Component

Parts Location" (K9K).

2. TCM*1

Refer to TM-314, ...