Nissan Juke Service and Repair Manual : P012A TC boost sensor

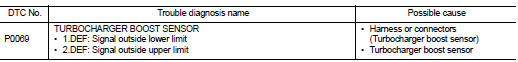

DTC Logic

DTC DETECTION LOGIC

Diagnosis Procedure

1.CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Check ground connection E38. Refer to Ground inspection in GI-44, "Circuit Inspection".

Is the inspection result normal? YES >> GO TO 2.

NO >> Repair or replace ground connection.

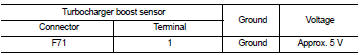

2.CHECK TUBOCHARGER BOOST SENSOR SUPPLY CIRCUIT

1. Disconnect turbocharger boost sensor harness connector.

2. Turn ignition switch ON.

3. Check the voltage between turbocharger boost sensor connector and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair open circuit or short to ground or short to power in harness or connectors.

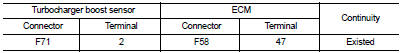

3.CHECK TUBOCHARGER BOOST SENSOR GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check the continuity between turbocharger boost sensor harness connector and ECM harness connector

4. Also check harness for short to ground and short to power.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair open circuit or short to ground or short to power in harness or connectors.

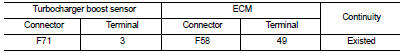

4.CHECK TUBOCHARGER BOOST SENSOR INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Check the continuity between turbocharger boost sensor harness connector and ECM harness connector.

2. Also check harness for short to ground and short to power.

Is the inspection result normal?

YES >> GO TO 5.

NO >> Repair open circuit or short to ground or short to power in harness or connectors.

5.CHECK TUBOCHARGER BOOST SENSOR

Refer to EC-912, "Component Inspection".

Is the inspection result normal? YES >> GO TO 6.

NO >> Replace turbocharger boost sensor.

6.REPLACE ECM

1. Perform EC-879, "Work Procedure".

2. Perform EGR volume control valve closed position learning. Refer to EC-881, "Work Procedure".

>> INSPECTION END

Component Inspection

1.CHECK TURBOCHARGER BOOST SENSOR-I

1. Turn ignition switch OFF.

2. Remove turbocharger boost sensor with its harness connected.

3. Turn ignition switch ON.

4. Select ???DATA MONITOR??? mode with CONSULT-III.

5. Check ???BOOST PRESS??? and ???ATOMOS PRESS??? indication.

If the value is not very close to ???ATOMOS PRESS???, maximum pressure difference between ???ATOMOS PRESS??? and ???BOOST PRESS??? with the ignition switch ON (engine stop) = ?± 50 mbar? YES >> GO TO 2.

NO >> Replace turbocharger boost sensor.

2.CHECK TURBOCHARGER BOOST SENSOR-II

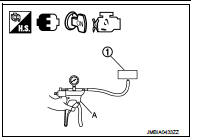

1. Use pump (A) to apply turbocharger boost sensor (1) as shown in the figure.

2. Apply a pressure of between 10 kPa (0.100 bar, 0.102 kg/cm2, 1.5 psi) - 13 kPa (0.130 bar, 0.133 kg/cm2, 1.9 psi) [maximum pressure to be applied: 13 kPa (0.130 bar, 0.133 kg/cm2, 1.9 psi)].

3. Select ???DATA MONITOR??? mode with CONSULT-III.

4. Check ???BOOST PRESS??? indication with that given by the vacuum pump.

If there is no discrepancy? YES >> INSPECTION END

NO >> Replace turbocharger boost sensor.

P0120 TP sensor

P0120 TP sensor

DTC Logic

DTC DETECTION LOGIC

Diagnosis Procedure

1.CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF and wait at least 20 seconds.

2. Check ground connection E38. Refer to Ground inspection ...

P012B TC boost sensor

P012B TC boost sensor

DTC Logic

DTC DETECTION LOGIC

Diagnosis Procedure

1.CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Check ground connection E38. Refer to Ground inspection in GI-44, "Circuit

In ...

Other materials:

Power supply and ground circuit

Diagnosis Procedure

1.CHECK FUSES AND FUSIBLE LINK

Check that the following IPDM E/R fuses or fusible links are not blown.

Is the fuse fusing?

YES >> Replace the blown fuse or fusible link after repairing the affected

circuit if a fuse or fusible link is

blown.

NO >> GO TO 2. ...

High pressure supply pump

Exploded View

1. High pressure supply pump protector

2. High pressure supply pump

: N·m (kg-m, ft-lb)

Removal and Installation

REMOVAL

CAUTION:

• Be sure to read “Precautions for Diesel Equipment”. Refer to EM-263,

"Precaution for Diesel Equipment".

• Wait until the fuel tempe ...

Service data and specifications (SDS)

Compressor

Lubricant

Refrigerant

Engine Idling Speed

Refer to EC-807, "Idle Speed".

Belt Tension

Refer to EM-154, "Checking". ...