Nissan Juke Service and Repair Manual : Oil pan (upper)

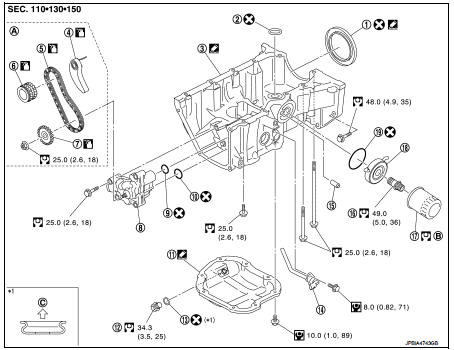

Exploded View

With Oil Cooler

1. Rear oil seal

2. O-ring

3. Oil pan (upper)

4. Oil pump chain tensioner (for oil

pump drive chain)

5. Oil pump drive chain

6. Crankshaft sprocket

7. Oil pump sprocket

8. Oil pump

9. O-ring

10. O-ring

11. Oil pan (lower)

12. Oil pan drain plug

13. Drain plug washer

14. Oil level sensor

15. Relief valve

16. Connector bolt

17. Oil filter

18. Oil cooler

19. O-ring

A. Refer to EM-182

B. Refer to LU-28

C. Oil pan (lower) side

: Always replace after every

: Always replace after every

disassembly.

: N·m (kg-m, in-lb)

: N·m (kg-m, in-lb)

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

: Sealing point

: Sealing point

: Should be lubricated with oil.

: Should be lubricated with oil.

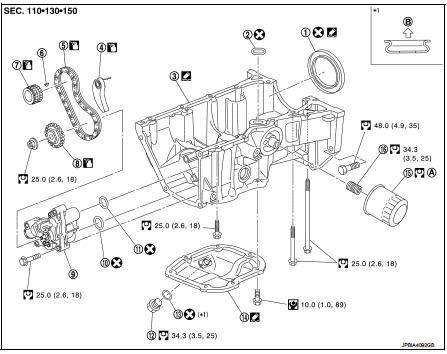

With Out Oil Cooler

1. Rear oil seal

2. O-ring

3. Oil pan (upper)

4. Oil pump chain tensioner (for oil

pump drive chain)

5. Oil pump drive chain

6. Crankshaft key

7. Crankshaft sprocket

8. Oil pump sprocket

9. Oil pump

10. O-ring

11. O-ring

12. Oil pan drain plug

13. Drain plug washer

14. Oil pan (lower)

15. Oil filter

16. Oil filter stud bolt

A. Refer to EM-182

B. Refer to LU-28

C. Oil pan (lower) side

: Always replace after every

: Always replace after every

disassembly.

: N·m (kg-m, in-lb)

: N·m (kg-m, in-lb)

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

: Sealing point

: Sealing point

: Should be lubricated with oil..

: Should be lubricated with oil..

Removal and Installation

NOTE

:

The oil strainer and oil pump are included in the oil pan (upper). Individual

disassembly is prohibited.

REMOVAL

1. Remove the oil pan (lower). Refer to EM-169, "Exploded View".

2. Remove oil pump sprocket and crankshaft sprocket together with oil pump drive chain. Refer to EM-181, "Exploded View".

3. Remove oil pan (upper) with the following procedure.

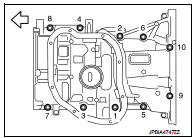

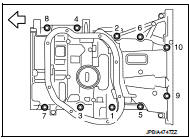

a. Loosen oil pan (upper) mounting bolts in the reverse of the order as shown in the figure.

: Engine front

: Engine front

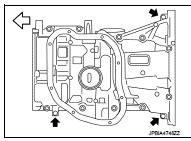

b. Insert a flat-bladed offset screwdriver into the arrow (

) in the

figure and open up a crack between the oil pan (upper) cylinder

block.

![c. Insert the seal cutter [SST: KV10111100] between the oil pan](images/books/335/5/index.101.gif) : Engine front

: Engine front

c. Insert the seal cutter [SST: KV10111100] between the oil pan (upper) and cylinder block. Slide seal cutter by tapping on the side of tool with a hammer.

CAUTION:

• Be careful not to damage the mating surface.

• A more adhesive liquid gasket is applied compared to previous types when shipped, so it should not be forced off using a screwdriver, etc. outside the indicated location.

• Never remove oil pump and oil strainer from oil pan (upper).

4. Remove rear oil seal from crankshaft.

INSTALLATION

1. Install the oil pan (upper) in the following procedure: a. Use scraper to remove old liquid gasket from mating surfaces.

• Also remove the old liquid gasket from mating surface of cylinder block.

• Remove old liquid gasket from the bolt holes and threads.

CAUTION:

Never scratch or damage the mating surfaces when cleaning off old liquid gasket.

b. Install O-ring to the cylinder block.

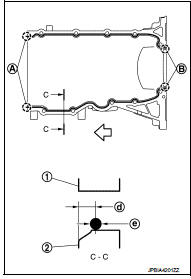

c. Apply a continuous bead of liquid gasket (C) with the tube presser (commercial service tool) to areas as shown in the figure.

Use Genuine Liquid Gasket or equivalent.

A : 2 mm (0.07 in) protruded to outside

B : 2 mm (0.07 in) protruded to rear oil seal mounting side

d : 5.5 - 7.5 mm (0.217 - 0.295 in)

e : φ4.0 - 5.0 mm (0.157 - 0.197 in)

: Engine front side

: Engine front side

: Engine out side

: Engine out side

A : Excess of 2 mm or more outward

B : Excess of 2 mm or more in the rear oil seal mounting direction

CAUTION:

Attaching should be done within 5 minutes after coating.

d. Tighten bolts in the numerical order as shown in the figure.

: Engine front

: Engine front

CAUTION:

Install avoiding misalignment of both oil pan gasket and Oring.

• The bolts are different according to the installation position.

Refer to the numbers as shown in the figure.

M8×180 mm (7.09 in) : No. 9, 10 M8×25 mm (0.98 in) : No. 3, 4, 7, 8 M8×90 mm (3.54 in) : No. 1, 2, 5, 6

2. Install rear oil seal with the following procedure:

CAUTION:

• The installation of rear oil seal should be completed within 5 minutes after

installing oil pan

(upper).

• Never touch oil seal lip.

a. Wipe off any liquid gasket protruding to the rear oil seal mounting part of oil pan (upper) and cylinder block using a spatula.

b. Apply the liquid gasket lightly to entire outside area of new rear oil seal.

Use Genuine Liquid Gasket or equivalent.

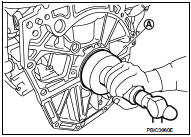

c. Press-fit the rear oil seal using a drift with outer diameter 113 mm (4.45 in) and inner diameter 90 mm (3.54 in) (commercial service tool) (A).

• Press-fit to the dimensions specified as shown in the figure.

1 : Rear oil seal

A : Rear end surface of cylinder block

b : 0 - 0.5 mm (0 - 0.020 in)

CAUTION:

• Never touch the grease applied to the oil seal lip.

• Be careful not to damage the rear oil seal mounting part of oil pan (upper) and cylinder block or the crankshaft.

• Press-fit straight check that oil seal does not curl or tilt.

d. After press-fitting the rear oil seal, completely wipe off any liquid gasket protruding to rear end surface side.

3. Install in the reverse order of removal, for the rest of parts.

Inspection

INSPECTION AFTER INSTALLATION

1. Check engine oil level and adjust engine oil. Refer to LU-25, "Inspection".

2. Check for leakage of engine oil when engine is warmed.

3. Stop engine and wait for 10 minutes.

4. Check engine oil level again. Refer to LU-25, "Inspection".

Engine unit

Engine unit

Disassembly

1. Remove intake manifold. Refer to EM-163, "Exploded View".

2. Remove exhaust manifold. Refer to EM-166, "Exploded View".

3. Remove oil pan (lower). Refer to EM-16 ...

Cylinder block

Cylinder block

Exploded View

1. Crankshaft position sensor (POS) cover

2. Crankshaft position sensor (POS)

3. O-ring

4. Drain plug

5. Cylinder block

6. Oil level gauge

7. Oil level gauge guide

8. O-ri ...

Other materials:

Engine stand setting

NOTE:

Explained here is how to disassemble with engine stand supporting transaxle

surface. When using different

type of engine stand, note with difference in steps and etc.

1. Remove the engine and the transaxle assembly from the vehicle, and separate

the transaxle from the

engine. Refer t ...

Component parts

Component Parts Location

LHD models

1. ABS actuator and electric unit (control

unit)

Refer to BRC-97, "Component Parts

Location".

2. ECM

Refer to EC-25, "ENGINE CONTROL

SYSTEM :

Component Parts Location".

3. Front wheel sensor

Refer to BRC-97, "Component Parts

...

Speed limiter

SPEED LIMITER : Switch Name and Function

SWITCHES AND INDICATORS

NOTE:

Shared with ASCD switch.

1. Speed limiter indicator

2. SET indicator

3. Set speed indicator

4. CANCEL switch

5. RES / + switch

6. SET / − switch

7. Speed limiter MAIN Switch

8. ASCD MAIN switch

A. On the ...