Nissan Juke Service and Repair Manual : Luggage room lamp

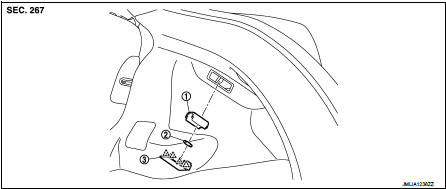

Exploded View

1. Bulb housing

2. Bulb

3. Lens

: Pawl

: Pawl

Removal and Installation

CAUTION:

Disconnect the battery cable from negative terminal or remove the fuse.

REMOVAL

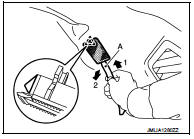

1. Insert a remover tool (A) into the gap between luggage room lamp and luggage side lower finisher RH.

2. Disengage luggage room lamp fixing pawl, and then disconnect luggage room lamp harness connector.

: Pawl

: Pawl

3. Remove luggage room lamp from luggage side lower finisher RH.

INSTALLATION

Install in the reverse order of removal.

Replacement

CAUTION:

• Disconnect the battery cable from negative terminal or remove the fuse.

• Never touch the glass of bulb directly by hand. Keep grease and other oily substaces away from it. Never touch bulb by hand while it is lit or right after it is off.

• Never leave bulb out of lamp reflector for a long time because dust, moisture smoke, etc. may affect the performance of lamp. When replacing bulb, be sure to replace it with a new one.

LUGGAGE ROOM LAMP BULB

1. Remove the luggage room lamp.

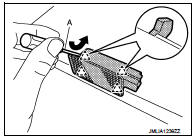

2. Insert a remover tool (A) into the gap between the lens and bulb housing, and then disengage fixing pawls as shown by the arrow in the figure.

: Pawl

: Pawl

3. Remove the bulb.

Map lamp

Map lamp

Exploded View

1. Map lamp bulb housing

2. Bulb

3. Lens

: Pawl

Removal and Installation

CAUTION:

Disconnect the battery negative terminal or the fuse.

REMOVAL

1. Remove the lens (1).

• In ...

Service data and specifications (SDS)

Service data and specifications (SDS)

Bulb Specifications

*: With intelligent key ...

Other materials:

P0544 EGT sensor 1

DTC Logic

DTC DETECTION LOGIC

Diagnosis Procedure

1.CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Check ground connection E38. Refer to Ground inspection in GI-44, "Circuit

Inspection".

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair or ...

Connector Information/Explanation of Option Abbreviation

CONNECTOR LIST

Connector information and harness layout are described in “POWER SUPPLY,

GROUND & CIRCUIT ELEMENTS”

Section.

EXPLANATION OF OPTION ABBREVIATION

HOW TO USE CONNECTOR INFORMATION

Description

...

Operation inspection

Work Procedure

The purpose of the operational check is to check that the individual system

operates normally.

Check condition : Engine running at normal operating temperature.

1.CHECK BLOWER MOTOR

1. Operate fan control dial.

2. Check that fan speed changes. Check operation for all fan speeds ...