Nissan Juke Service and Repair Manual : Intelligent key warning buzzer

Component Function Check

1.CHECK FUNCTION

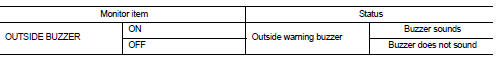

1. Select “INTELLIGENT KEY” of “BCM” using CONSULT-III.

2. Select “OUTSIDE BUZZER” in “ACTIVE TEST” mode.

3. Check that the function operates normally according to the following conditions.

Is the inspection result normal? YES >> Intelligent Key warning buzzer is OK.

NO >> Refer to DLK-92, "Diagnosis Procedure".

Diagnosis Procedure

1.CHECK FUSE

1. Turn ignition switch OFF.

2. Check 10 A fuse, [No. 7, located in fuse block (J/B)].

Is the inspection result normal? YES >> GO TO 2.

NO >> Replace the blown fuse after repairing the affected circuit if a fuse is blown.

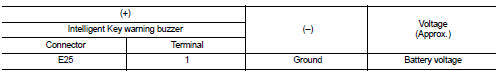

2.CHECK INTELLIGENT KEY WARNING BUZZER POWER SUPPLY CIRCUIT

1. Disconnect Intelligent Key warning buzzer connector.

2. Check voltage between Intelligent Key warning buzzer harness connector and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair or replace harness.

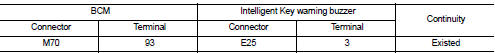

3.CHECK INTELLIGENT KEY WARNING BUZZER CIRCUIT

1. Disconnect BCM connector.

2. Check continuity between BCM harness connector and Intelligent Key warning buzzer harness connector.

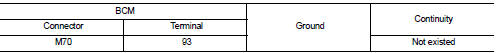

3. Check continuity between BCM harness connector and ground.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair or replace harness.

4.CHECK INTELLIGENT KEY WARNING BUZZER

Refer to DLK-93, "Component Inspection".

Is the inspection result normal? YES >> Replace BCM. Refer to BCS-93, "Removal and Installation".

NO >> Replace Intelligent Key warning buzzer.

Component Inspection

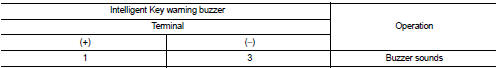

1.CHECK INTELLIGENT KEY WARNING BUZZER

1. Turn ignition switch OFF.

2. Disconnect Intelligent Key warning buzzer connector.

3. Connect battery power supply directly to Intelligent Key warning buzzer terminals and check the operation.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace Intelligent Key warning buzzer.

Intelligent key

Intelligent key

Component Function Check

1.CHECK FUNCTION

1. Select “INTELLIGENT KEY” of “BCM” using CONSULT-III.

2. Select “RKE OPE COUN1” in “DATA MONITOR” mode.

3. Check that the function operates normally acc ...

Key warning lamp

Key warning lamp

Component Function Check

1.CHECK FUNCTION

1. Select “INTELLIGENT KEY” of “BCM” using CONSULT-III.

2. Select “INDICATOR” in “ACTIVE TEST” mode.

3. Check that the function operates normally accordin ...

Other materials:

Vehicle security system cannot be set

Key fob

KEY FOB : Description

Armed phase is not activated when door is locked using keyfob.

NOTE:

Check that vehicle is under the condition shown in “CONDITIONS OF VEHICLE

(OPERATING CONDITIONS)”

before starting diagnosis, and check each symptom.

CONDITION OF VEHICLE (OPERATING CONDITIO ...

Multi display unit

Reference Value

VALUES ON THE DIAGNOSIS TOOL

• *1:MR16DDT

• *2: This is not used to determine ON/OFF of the indicator lamp.

TERMINAL LAYOUT

PHYSICAL VALUES

DTC Inspection Priority Chart

When multiple DTCs are displayed simultaneously, check one by one according

to the following prio ...

Sun visors

TILT OPERATION

Push the lock lever down 1 and adjust the steering wheel up or down 2 to the

desired position.

Pull the lock lever up 3 securely to lock the steering wheel in place.

1. To block out glare from the front, swing down the sun visor1 .

2. To block glare from the side, remove the ...