Nissan Juke Service and Repair Manual : Input shaft and gear

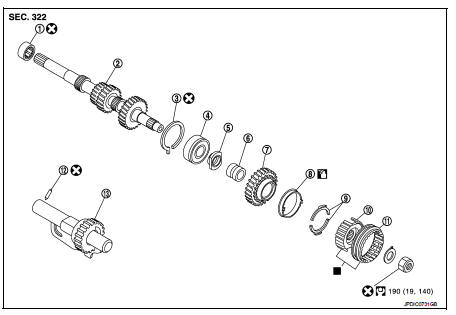

Exploded View

1. Input shaft front bearing

2. Input shaft

3. Snap ring

4. Input shaft rear bearing

5. Adapter plate

6. Bushing

7. 5th input gear

8. 5th-reverse baulk ring

9. Synchronizer lever

10. 5th-reverse synchronizer hub

11. 5th-reverse coupling sleeve

12. Retaining pin

13. Reverse gear

: Apply gear oil.

: Apply gear oil.

: Replace the parts as a set.

: Replace the parts as a set.

: Always replace after every

: Always replace after every

disassembly.

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

Disassembly

Refer to TM-37, "Disassembly" for disassembly procedure.

Assembly

Refer to TM-43, "Assembly" for assembly procedure.

Inspection

INSPECTION AFTER DISASSEMBLY

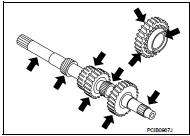

Input Shaft and Gear

Check the following items and replace if necessary.

• Damage, peeling, bend, uneven wear, and distortion of shaft.

• Excessive wear, damage, and peeling of gear.

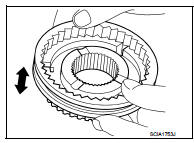

Synchronizer Hub and Coupling Sleeve Check the following items and replace if necessary.

• Breakage, damage, and unusual wear on contact surface of coupling sleeve, synchronizer hub, and insert key.

• Coupling sleeve and synchronizer hub move smoothly.

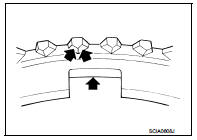

Baulk RingBaulk Ring Check contact surface of baulk ring cam and insert key for excessive wear, uneven wear, bend, and damage. Replace if necessary.

Check contact surface of baulk ring cam and insert key for excessive wear, uneven wear, bend, and damage. Replace if necessary.

Bearing

Check bearing for damage and unsmooth rotation. Replace if necessary.

Transaxle assembly

Transaxle assembly

Exploded View

CASE AND HOUSING

1. Differential side oil seal

2. Clutch housing

3. 2 way connector

4. Oil gutter

5. Air breather inner tube

6. Filler plug

7. Gasket

8. Transaxle case

9 ...

Mainshaft and gear

Mainshaft and gear

Exploded View

1. Mainshaft front bearing outer

race

2. Mainshaft front bearing inner race

3. Mainshaft

4. 1st main gear

5. 1st inner baulk ring

6. 1st synchronizer cone

7. 1st outer baulk ...

Other materials:

Diagnosis system (IPDM E/R) (without intelligent key system)

Diagnosis Description

AUTO ACTIVE TEST

Description

In auto active test mode, the IPDM E/R sends a drive signal to the following

systems to check their operation.

• Oil pressure warning lamp (only for K9K engine models)

• Rear window defogger

• Front wiper motor

• Parking lamp

• License p ...

Door mirror system (without intelligent key)

LHD

LHD : Wiring Diagram

For connector terminal arrangements, harness layouts, and alphabets in a

(option abbreviation; if not

described in wiring diagram), refer to GI-12, "Connector Information/Explanation

of Option Abbreviation".

RHD

RHD : Wiring Diagram

For connector termina ...

Stop lamp switch

Component Function Check

1.CHECK STOP LAMP SWITCH OPERATION

Depress brake pedal and check that stop lamp turns ON, or release brake pedal

and check stop lamp turns

OFF.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Check stop lamp system. Refer to EXL-39, "Wirin ...