Nissan Juke Service and Repair Manual : Electrical load signal

Description

The electrical load signal (Headlamp switch signal, rear window defogger switch signal, etc.) is transferred to ECM through the CAN communication line.

Component Function Check

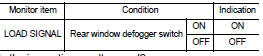

1.CHECK REAR WINDOW DEFOGGER SWITCH FUNCTION

1. Turn ignition switch ON.

2. Select “DATA MONITOR” mode with CONSULT-III.

3. Select “LOAD SIGNAL” and check indication under the following conditions.

Is the inspection result normal? YES >> GO TO 2.

NO >> Go to EC-776, "Diagnosis Procedure".

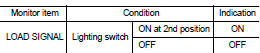

2.CHECK LIGHTING SWITCH FUNCTION

Check “LOAD SIGNAL” indication under the following conditions.

Is the inspection result normal? YES >> GO TO 3.

NO >> Go to EC-776, "Diagnosis Procedure".

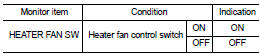

3.CHECK HEATER FAN CONTROL SWITCH FUNCTION

Select “HEATER FAN SW” and check indication under the following conditions.

Is the inspection result normal? YES >> INSPECTION END

NO >> Go to EC-776, "Diagnosis Procedure".

Diagnosis Procedure

1.INSPECTION START

Confirm the malfunctioning circuit (rear window defogger, headlamp or heater fan). Refer to EC-776, "Component Function Check".

Which circuit is related to the incident? Rear window defogger>>GO TO 2 Headlamp>>GO TO 3.

Heater fan>>GO TO 4.

2.CHECK REAR WINDOW DEFOGGER SYSTEM

Perform trouble diagnosis of rear window defogger system. Refer to DEF-25, "Work Flow".

>> INSPECTION END

3.CHECK HEADLAMP SYSTEM

Perform trouble diagnosis of headlamp system. Refer to EXL-43, "Work Flow".

>> INSPECTION END

4.CHECK AIR CONDITIONING SYSTEM

Perform trouble diagnosis of air conditioning system. Check type of air conditioning system HAC-10, "Information" and refer to the follows.

• TYPE1: HAC-44, "Work Flow" • TYPE2: HAC-135, "Work Flow" • TYPE3: HAC-216, "Work Flow" • TYPE4: HAC-271, "Work Flow" • TYPE5: HAC-322, "Work Flow"

>> INSPECTION END

Cooling fan

Cooling fan

Component Function Check

1.CHECK COOLING FAN FUNCTION

With CONSULT-III

1. Turn ignition switch ON.

2. Perform “COOLING FAN” in “ACTIVE TEST” mode with CONSULT-III.

3. Touch “LOW” and “Hi” on the ...

Fuel injector

Fuel injector

Component Function Check

1.INSPECTION START

Turn ignition switch to START.

Is any cylinder ignited?

YES >> GO TO 2.

NO >> Go to EC-778, "Diagnosis Procedure".

2.CHECK ...

Other materials:

U1010 control unit (can)

Description

CAN (Controller Area Network) is a serial communication line for real time

application. It is an on-vehicle multiplex

communication line with high data communication speed and excellent error

detection ability. Many electronic

control units are equipped onto a vehicle, and each co ...

B2562 low voltage

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.DTC CONFIRMATION

1. Erase DTC.

2. Turn ignition switch OFF.

3. Perform the “Self Diagnostic Result” of BCM with CONSULT-III, when passed 120

seconds or more after

the ignition switch is turned ON.

Is any DTC detected?

YES > ...

B1178 lap Pre-tensioner RH

DTC Logic

DTC CONFIRMATION PROCEDURE

1.CHECK SELF-DIAGNOSTIC RESULT

With CONSULT-III

1. Turn ignition switch ON.

2. Perform “Self Diagnostic Result” mode of “AIR BAG” using CONSULT-III.

Without CONSULT-III

1. Turn ignition switch ON.

2. Check the air bag warning lamp status. Refer to SRC ...