Nissan Juke Service and Repair Manual : ECU diagnosis information

4WD control module

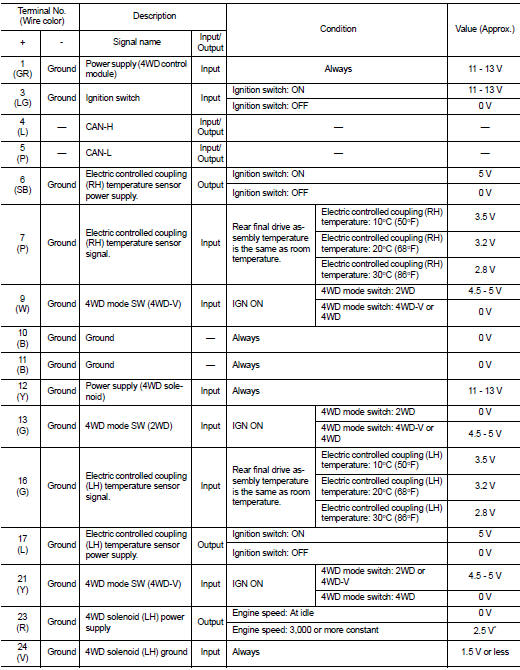

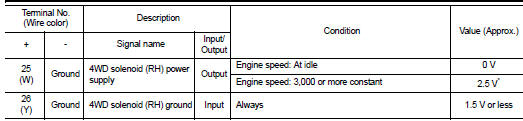

Reference Value

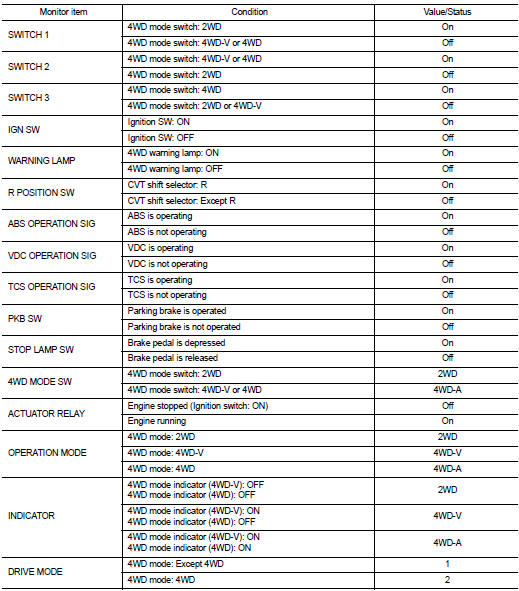

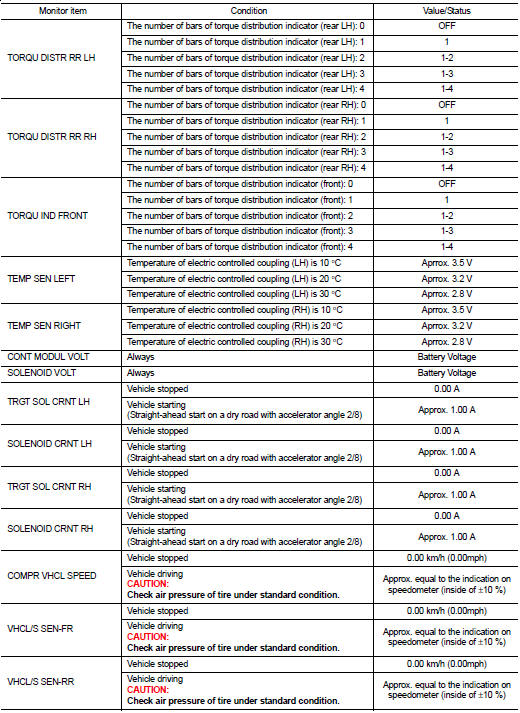

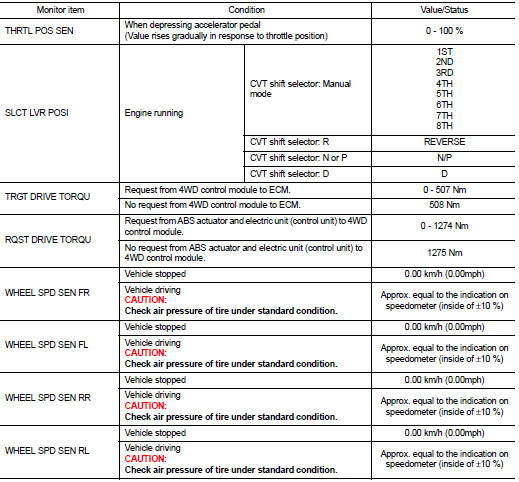

VALUES ON THE DIAGNOSIS TOOL

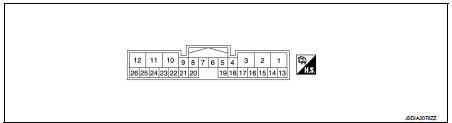

TERMINAL LAYOUT

PHYSICAL VALUES

*: The values are changed by throttle opening and engine speed.

CAUTION:

When using circuit tester to measure voltage for inspection, be sure not to

extend forcibly any connector

terminals.

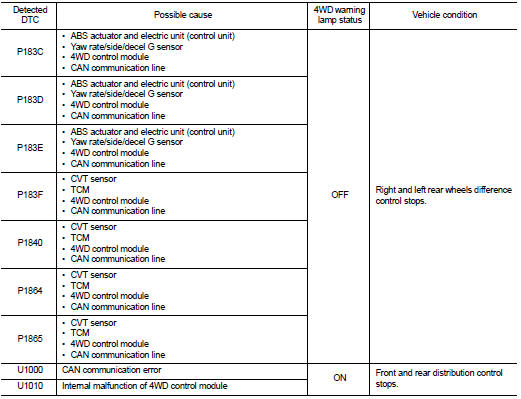

Fail-safe

When a system malfunction occurs, the 4WD warning lamp turns ON and the 4WD control becomes 2WD state.

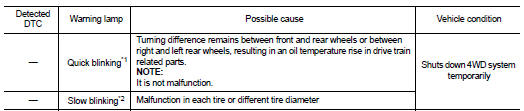

Protection Function

4WD system activates its protection function (shuts down 4WD system temporarily) if 4WD system detects high load continuously, the front wheel tire size differs from the rear tire size or the rear RH wheel tire size differs from the rear LH tire size. (4WD system is automatically restored if 4WD system no longer detects any overload or the tire size difference is eliminated.)

*1: 2 times/second (blinking for approximately 1 minute and then turned

OFF)

*2: 1 time/2 seconds (continuing to blink until ignition switch is turned OFF)

NOTE

:

• If the warning lamp blinks slowly during driving but remains OFF after the

engine is restarted, the system is

normal. If it again blinks slowly after driving for some time, vehicle must be

inspected.

• When there is a difference of revolution speed between the front and rear wheel the shift occasionally changes to direct 4-wheel driving conditions automatically. This is not a malfunction.

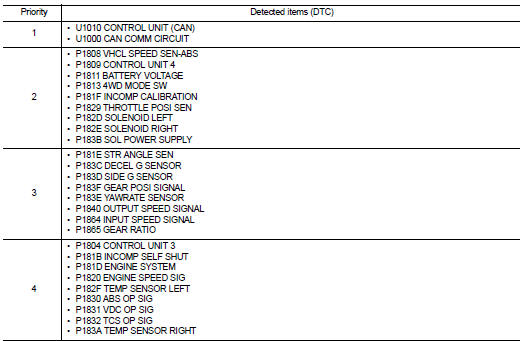

DTC Inspection Priority Chart

If some DTCs are displayed at the same time, perform inspections one by one based on the following priority chart.

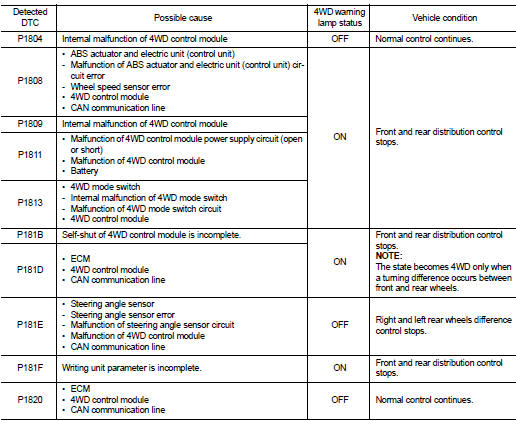

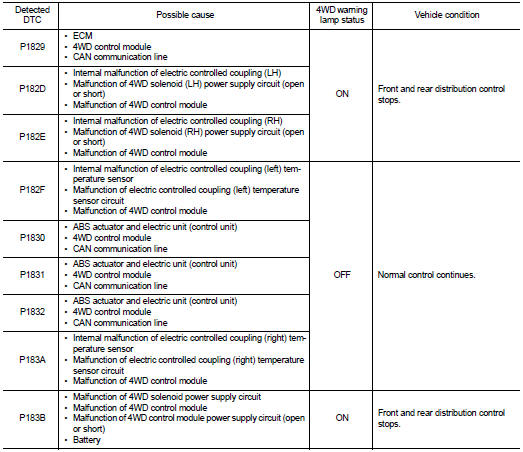

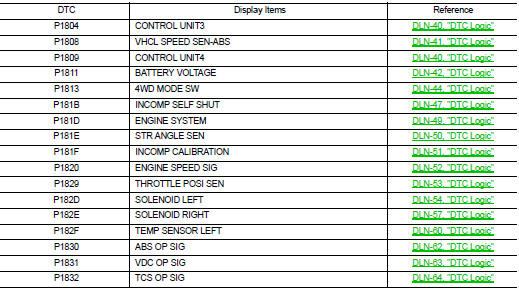

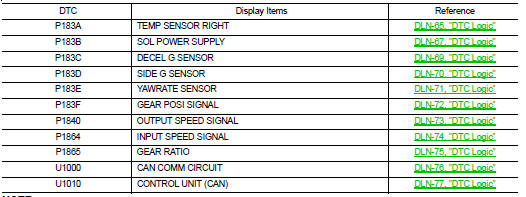

DTC Index

NOTE

:

If some DTCs are displayed at the same time, refer to DLN-33, "DTC Inspection

Priority Chart".

Diagnosis system (4WD control module)

Diagnosis system (4WD control module)

CONSULT-III Function

APPLICATION ITEMS

CONSULT-III can display each diagnostic item using the diagnostic test modes

as follows.

*: The following diagnosis information is erased by erasing.

• ...

Wiring diagram

Wiring diagram

4WD SYSTEM

Wiring Diagram

For connector terminal arrangements, harness layouts, and alphabets in a

(option abbreviation; if not

described in wiring diagram), refer to GI-12, "Connector Inform ...

Other materials:

Passenger compartment

CAUTION

Never use a fuse of a higher or lower amperage rating than that specified

on the fuse box cover. This could damage the electrical system or cause a fire.

If any electrical equipment does not operate, check for an open fuse.

1. Be sure the ignition switch and the headlight switch are t ...

Changing engine coolant

Major cooling system repairs should be performed by a NISSAN dealer. The service

procedures can be found in the appropriate NISSAN Service Manual.

Improper servicing can result in reduced heater performance and engine overheating.

WARNING

• To avoid the danger of being scalded, never change the ...

Cylinder head

Exploded View

1. Camshaft sprocket

2. Cylinder head suspended bracket

3. Valve lifter

4. Valve rotator

5. Valve spring retainer

6. Valve spring

7. Exhaust valve

8. Intake valve

9. Valve collet

10. Cap

11. Rear engine slinger

12. Cylinder head gasket

13. Cylinder head

14. Cam ...