Nissan Juke Service and Repair Manual : DTC/circuit diagnosis

Blower motor

Diagnosis Procedure

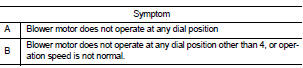

1.CHECK SYMPTOM

Check symptom (A or B).

Which symptom is detected? A >> GO TO 2.

B >> GO TO 7.

2.CHECK FUSE

1. Turn ignition switch OFF.

2. Check 15A fuses (Nos. 14 and 16, located in fuse block (J/B)].

NOTE

:

Refer to PG-22, "Fuse, Connector and Terminal Arrangement".

Is the inspection result normal? YES >> GO TO 3.

NO >> Replace the blown fuse after repairing the affected circuit if a fuse is blown.

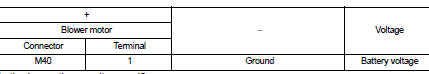

3.CHECK BLOWER MOTOR POWER SUPPLY

1. Disconnect blower motor connector.

2. Turn ignition switch ON.

3. Check voltage between blower motor harness connector and ground.

Is the inspection result normal? YES >> GO TO 5.

NO >> GO TO 4.

4.CHECK BLOWER RELAY

1. Turn ignition switch OFF.

2. Check blower relay. Refer to HAC-327, "Component Inspection (Blower Relay)".

Is the inspection result normal? YES >> Repair harness or connector between blower motor and fuse.

NO >> Replace blower relay.

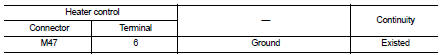

5.CHECK FAN SWITCH GROUND CIRCUIT FOR OPEN

1. Turn ignition switch OFF.

2. Disconnect heater control connector.

3. Check continuity between heater control harness connector and ground.

Is the inspection result normal? YES >> GO TO 6.

NO >> Repair harness or connector.

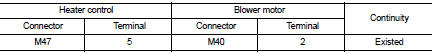

6.CHECK FAN SWITCH 4 POSITION CIRCUIT FOR OPEN

Check continuity between heater control harness connector and blower motor harness connector.

Is the inspection result normal? YES >> GO TO 10.

NO >> Repair the harness or connector.

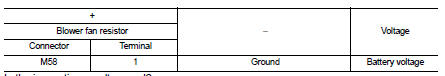

7.CHECK BLOWER FAN RESISTOR POWER SUPPLY

1. Turn ignition switch OFF.

2. Disconnect blower fan resistor connector.

3. Turn ignition switch ON.

4. Check voltage between blower fan resistor harness connector and ground.

Is the inspection result normal? YES >> GO TO 8.

NO >> Repair harness or connector between blower fan resistor and blower motor.

8.CHECK BLOWER FAN RESISTOR

1. Turn the ignition switch OFF.

2. Check blower fan resistor. Refer to HAC-327, "Component Inspection (Blower Fan Resistor)".

Is the inspection result normal? YES >> GO TO 9.

NO >> Replace blower fan resistor. Refer to HAC-332, "Removal and Installation".

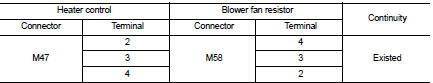

9.CHECK FAN SWITCH 1, 2, 3 POSITION CIRCUIT FOR OPEN

Check continuity between heater control harness connector and blower fan resistor.

Is the inspection result normal? YES >> GO TO 10.

NO >> Repair harness or connector.

10.CHECK FAN SWITCH

Check fan switch. Refer to HAC-328, "Component Inspection (Fan Switch)".

Is the inspection result normal? YES >> Replace blower motor. Refer to VTL-15, "Removal and Installation (LHD models)" or VTL-16, "Removal and Installation (RHD models)".

NO >> Replace heater control. Refer to HAC-331, "Removal and Installation".

Component Inspection (Blower Motor

)

1.CHECK BLOWER MOTOR

1. Remove blower motor. Refer to VTL-15, "Removal and Installation (LHD models)" or VTL-16, "Removal and Installation (RHD models)".

2. Check that there is not any mixing foreign object in the blower motor.

Is the inspection result normal? YES >> GO TO 2.

NO >> Replace blower motor. Refer to VTL-15, "Removal and Installation (LHD models)" or VTL-16, "Removal and Installation (RHD models)".

2.CHECK BLOWER MOTOR

Check that there is not breakage or damage in the blower motor.

Is the inspection result normal? YES >> GO TO 3.

NO >> Replace blower motor. Refer to VTL-15, "Removal and Installation (LHD models)" or VTL-16, "Removal and Installation (RHD models)".

3.CHECK BLOWER MOTOR

Check that blower motor turns smoothly.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace blower motor. Refer to VTL-15, "Removal and Installation (LHD models)" or VTL-16, "Removal and Installation (RHD models)".

Component Inspection (Blower Relay)

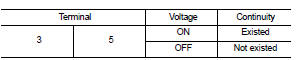

1.CHECK BLOWER RELAY

1. Remove blower relay. Refer to PG-22, "Fuse, Connector and Terminal Arrangement".

2. Check continuity between blower relay terminal 3 and 5 when the voltage is supplied between terminal 1 and 2.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace blower relay.

Component Inspection (Blower Fan Resistor)

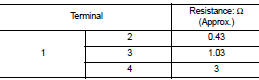

1.CHECK BLOWER FAN RESISTOR

1. Disconnect blower fan resistor connector.

2. Check resistance between blower fan resistor terminals. Refer to applicable table for the normal value.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace blower fan resistor. Refer to HAC-332, "Removal and Installation".

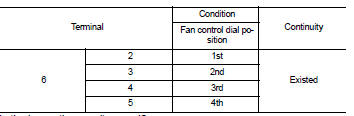

Component Inspection (Fan Switch)

1.CHECK FAN SWITCH

Check continuity between heater control terminals.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace heater control. Refer to HAC-331, "Removal and Installation".

Operation inspection

Operation inspection

Work Procedure

The purpose of the operational check is to check that the individual system

operates normally.

Check condition : Engine running at normal operating temperature.

1.CHECK BLOWER MOTO ...

Other materials:

EPS warning lamp does not turn off

Description

EPS warning lamp does not turn OFF several seconds after engine started.

Diagnosis Procedure

1.PERFORM SELF-DIAGNOSIS

With CONSULT-III

1. Turn the ignition switch OFF to ON.

2. Perform “EPS” self-diagnosis.

Is any DTC detected?

YES >> Check the DTC. Refer to STC-14, " ...

Precaution Necessary for Steering Wheel Rotation after Battery Disconnect

NOTE:

• Before removing and installing any control units, first turn the ignition

switch to the LOCK position, then disconnect

both battery cables.

• After finishing work, confirm that all control unit connectors are connected

properly, then re-connect both

battery cables.

• Always use CONS ...

NISSAN Advanced Air Bag System (front seats)

1. Crash zone sensor

2. Supplemental front-impact air bag modules

3. Front seat-mounted side-impact supplemental air bag modules

4. Occupant classification sensors (weight sensors)

5. Occupant classification system control unit

6. Roof-mounted curtain side-impact supplemental air bag inflator ...