Nissan Juke Service and Repair Manual : CVT position

Inspection and Adjustment

INSPECTION

1. Turn ON the ignition switch with the selector lever at the P position.

2. Press the selector button with the brake pedal depressed, and confirm that the lever can be shifted to positions other than P. Also confirm that shifting is not allowed from the P position to other position without depressing the brake pedal.

3. Move the selector lever and check for “excessive effort”, “sticking”, “noise” or “rattle”.

4. Confirm that selector lever stops at each position with the feel of engagement when it is moved through all the positions. Check whether or not the actual position the selector lever is in matches the position shown by the transaxle body.

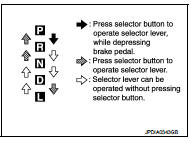

5. Make sure that the selector lever is shifted to all the shift positions in the manner shown in the figure.

6. When the selector button is pressed without applying forward/ backward force to the selector lever at “P”, “R”, “N” and “D” positions, there should be no “sticking” on the button operation.

7. The reverse lamp lights and the reverse warning buzzer sounds at the “R” position and the reverse lamp does not light and the reverse warning buzzer does not sound at other positions. Confirm that the buzzer does not sound when selector lever is in the “P” or “N” position, in particular, with the lever pushed against the “R” position.

8. Check that the engine can be started with the selector lever in the “P” and “N” positions only.

9. Check that the transaxle is locked when the selector lever is in the P position.

ADJUSTMENT

1. Shift the selector lever to the “P” position.

CAUTION:

Rotate the wheels at least a quarter turn and be certain the Park position

mechanism is fully

engaged.

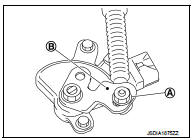

2. Remove nut (A) and set manual lever (B) to the “P” position.

CAUTION:

Do not apply force to the manual lever.

3. Tighten nuts to the specified torque. Refer to TM-485, "Exploded View".

CAUTION:

In tightening, fix the manual lever.

Line pressure test

Line pressure test

Work Procedure

INSPECTION

1. Check the engine oil level. Replenish if necessary. LU-25, "Inspection".

2. Check for leak of the CVT fluid. Refer to TM-480, "Inspection".

3. Driv ...

Other materials:

The oil pressure warning lamp does not turn on

Description

The oil pressure warning lamp stays off when the ignition switch is turned

ON.

Diagnosis Procedure

1.CHECK OIL PRESSURE WARNING LAMP

Perform auto active test. Refer to PCS-12, "Diagnosis Description" (with

I-KEY) or PCS-43, "Diagnosis

Description" (without I- ...

Precaution Necessary for Steering Wheel Rotation

after Battery Disconnect

NOTE:

• Before removing and installing any control units, first turn the push-button

ignition switch to the LOCK position,

then disconnect both battery cables.

• After finishing work, confirm that all control unit connectors are connected

properly, then re-connect both

battery cables.

• Alw ...

Wheel alignment

Inspection

DESCRIPTION

CAUTION:

• The adjustment mechanisms of camber, caster, and kingpin inclination angles

are not included.

• If camber, caster, or kingpin inclination angle is outside the standard, check

front suspension parts

for wear and damage. Replace suspect parts if a malfunction ...