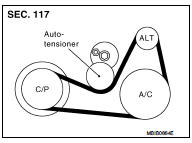

Nissan Juke Service and Repair Manual : Drive belt

Checking Drive Belts

WARNING:

Be sure to perform when the engine is stopped.

1. Inspect belts for cracks, fraying, wear and oil. If necessary, replace.

2. Evaluate manually if the belt is enough tensioned (tension cannot be measured by way of frequency meter).

CAUTION:

Auto-tensioner must be replaced with a new one when the

belt is replaced.

Tension Adjustment

Belt tensioning is not necessary, as it is automatically adjusted by auto-tensioner.

Removal and Installation

CAUTION: • Replace any belt that has been removed with a new one.

• Auto-tensioner must be replaced with new ones when the belt is replaced.

• Never run the engine without the drive belts to avoid damaging the crankshaft pulley

.

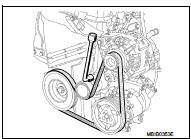

REMOVAL

1. Remove engine undercover.

2. Remove RH front wheel.

3. Remove fender protector RH. Refer to EXT-22, "Exploded View".

4. Remove drive belt.

• Turn clockwise adjusting bolt.

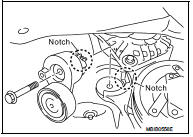

5. If necessary, remove auto-tensioner.

INSTALLATION

1. Install auto-tensioner mounting bolt.

Auto-tensioner mounting bolt : 40 N·m (4.1 kg-m, 30 ft-lb)

• Align the notch and tighten mounting bolt.

2. Install the drive belt.

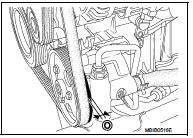

CAUTION:

• Make sure belt is correctly engaged with the pulley

groove.

• Check for oil and coolant on belt and each pulley groove.

• Certain drive belts have five teeth whereas the air conditioning compressor pulley, power-assisted steering pump pulley, and alternator pulley all have six teeth.In this case, it is essential to check that inner tooth (O) of the pulleys remains free when fitting the drive belt.

Never turn the engine in the opposite direction to its normal operating direction.

Use a brush to remove any deposits from the crankshaft pulley V grooves.

For engines fitted with a mechanical tensioning roller, it is essential to replace the tensioning roller mounting bolts.

3. Make sure that tension of each belt is within the standard.

Air cleaner filter

Air cleaner filter

Exploded View

1. Turbocharger air inlet pipe

2. Clamp

3. Air duct (suction)

4. Air mass flow sensor

5. O-ring

6. Air duct (inlet)

7. Grommet

8. Air cleaner case

9. Air cleaner filter

...

Other materials:

Spark plug

Removal and Installation

REMOVAL

1. Remove ignition coil. Refer to EM-178, "Exploded View".

2. Remove spark plug with a spark plug wrench (commercial service

tool).

a : 14 mm (0.55 in)

CAUTION:

Never drop or shock spark plug.

INSTALLATION

Install in the reverse order of removal ...

Speed limiter

SPEED LIMITER : Switch Name and Function

SWITCHES AND INDICATORS

NOTE:

Shared with ASCD switch.

1. Speed limiter indicator

2. SET indicator

3. Set speed indicator

4. CANCEL switch

5. RES / + switch

6. SET / − switch

7. Speed limiter MAIN Switch

8. ASCD MAIN switch

A. On the ...

Microphone signal circuit

Description

Power is supplied from NAVI control unit to microphone. The microphone

transmits the sound voice to the

NAVI control unit.

Diagnosis Procedure

1.CHECK CONTINUITY BETWEEN NAVI CONTROL UNIT AND MICROPHONE CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect NAVI control unit connecto ...