Nissan Juke Service and Repair Manual : Differential side oil seal

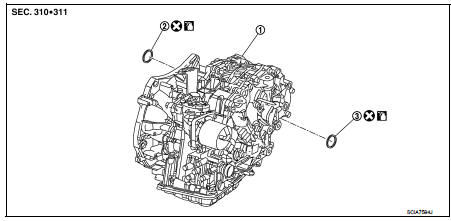

Exploded View

1. Transaxle assembly 2. Differential side oil seal (left side) 3. Differential side oil seal (right side)

: Always replace after every

: Always replace after every

disassembly.

: Genuine NISSAN CVT Fluid NS-2

: Genuine NISSAN CVT Fluid NS-2

Removal and Installation

REMOVAL

NOTE

:

Cap or plug openings to prevent fluid from spilling.

1. Remove the left front drive shaft. Refer to FAX-22, "LEFT SIDE : Removal and Installation".

2. Remove the transfer assembly. Refer to DLN-93, "Removal and Installation".

3. Use oil seal remover or a similar means and remove the differential side oil seal.

CAUTION:

When removing the differential side oil seal, be careful not to scratch the oil

seal mounting surfaces

of the transaxle case and converter housing.

INSTALLATION

Note the following, and install in the reverse order of removal.

CAUTION:

• Never reuse differential side oil seal.

• Apply Genuine NISSAN CVT Fluid NS-2 to the differential side oil seal lip and around the oil seal.

• When inserting the drive shaft, be sure to use a protector (SST: KV38107900). Refer to FAX-22, "LEFT SIDE : Removal and Installation".

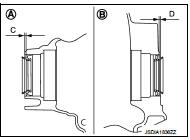

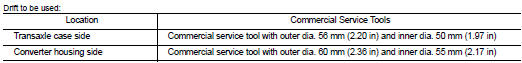

Use a drift (commercial service tool) and drive the differential side oil seal in until the amount of oil seal projection from the case edge matches dimensions (C) and (D).

CAUTION:

Be careful not to scratch the lip of the differential side oil seal

when press-fitting it.

A : Differential side oil seal (left side) B : Differential side oil seal (right side)

Dimension “C” :Height difference from case end surface is within 1.8 ± 0.5 mm (0.071 ± 0.020 in).

Dimension “D” :Height difference from case end surface is within 1.0 ± 0.5 mm (0.039 ± 0.020 in).

NOTE

:

The reference is the pull-in direction of the differential side oil seal.

Inspection

After completing installation, check for CVT fluid leakage and CVT fluid level. Refer to TM-184, "Inspection".

Secondary speed sensor

Secondary speed sensor

Exploded View

1. Transaxle assembly

2. Secondary speed sensor

3. O-ring

: Always replace after every

disassembly.

: N·m (kg-m, in-lb)

: Genuine NISSAN CVT Fluid NS-2

Removal and Installat ...

Oil pump fitting bolt

Oil pump fitting bolt

Description

Replace the oil pump fitting bolt and the O-ring if oil leakage or exudes

from the oil pump fitting bol

Exploded View

1. Oil pump fitting bolt

2. O-ring

3. Transaxle assembly

: ...

Other materials:

Assembly and Installation

• Use torque wrench to tighten bolts or nuts to specification.

• When tightening nuts and bolts, as a basic rule, equally tighten in several

different steps starting with the

ones in center, then ones on inside and outside diagonally in this order. If the

order of tightening is specified,

do ...

On Board Diagnostic (OBD) System of Engine

The ECM has an on board diagnostic system. It will light up the malfunction

indicator (MI) to warn the driver of

a malfunction causing emission deterioration.

CAUTION:

• Be sure to turn the ignition switch OFF and disconnect the battery negative

cable before any repair

or inspection work. ...

B2098 ignition relay on stuck

Description

The ignition relay integrated in IPDM E/R is operated with ignition switch ON

signal from the ignition switch.

DTC Logic

DTC DETECTION LOGIC

1.PERFORM DTC CONFIRMATION PROCEDURE

1. Turn ignition switch ON.

2. Check DTC in “Self Diagnostic Result” mode of “IPDM E/R” using CONSUL ...