Nissan Juke Service and Repair Manual : Diagnosis and repair workflow

Work Flow

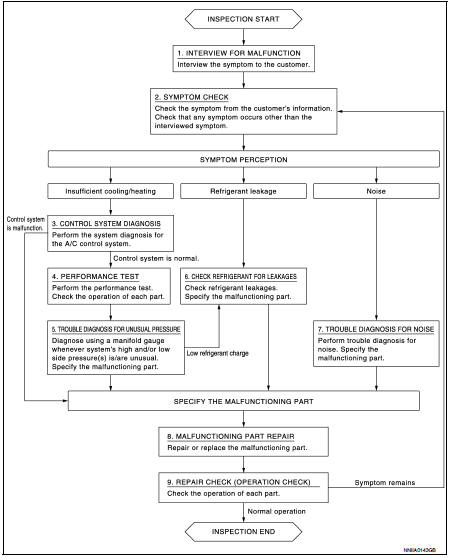

OVERALL SEQUENCE

DETAILED FLOW

1.INTERVIEW FOR MALFUNCTION

Interview the symptom to the customer

>> GO TO 2.

2.SYMPTOM CHECK

Check the symptom from the customer's information. Check that any symptom occurs other than the interviewed symptom.

Insufficient cooling/heating>>GO TO 3.

Refrigerant leakage>>GO TO 6.

Noise >> GO TO 7.

3.CONTROL SYSTEM DIAGNOSIS

Perform the system diagnosis for the A/C control system.

• Refer to HAC-135, "Work Flow". (AUTOMATIC AIR CONDITIONING) • Refer to HAC-271, "Work Flow". (MANUAL AIR CONDITIONING) • Refer to HAC-322, "Work Flow". (MANUAL HEATER)

Is A/C control system normal? YES >> GO TO 4.

NO >> GO TO 8.

4.PERFORMANCE TEST

Perform the performance test. Check the operation of each part. Refer to HA-26, "Inspection".

>> GO TO 5.

5.TROUBLE DIAGNOSIS FOR UNUSUAL PRESSURE

Diagnose using a manifold gauge whenever system's high and/or low side pressure(s) is/are unusual. Specify the malfunctioning part. Refer to HA-28, "Symptom Table".

Low refrigerant charge>>GO TO 6.

Except above>>GO TO 8.

6.CHECK REFRIGERANT FOR LEAKAGES

Check refrigerant for leakages. Specify the malfunctioning part. Refer to HA-19, "Leak Test".

>> GO TO 8.

7.TROUBLE DIAGNOSIS FOR NOISE

Perform trouble diagnosis for noise. Specify the malfunctioning part. Refer to HA-28, "Symptom Table".

>> GO TO 8.

8.MALFUNCTION PART REPAIR

Repair or replace the malfunctioning part.

>> GO TO 9.

9.REPAIR CHECK (OPERATION CHECK)

Check the operation of each part.

Does it operate normally? YES >> INSPECTION END

NO >> GO TO 2.

Basic inspection

Basic inspection

...

Refrigerant

Refrigerant

Description

CONNECTION OF SERVICE TOOLS AND EQUIPMENT

1. Shut-off valve

2. A/C service valve

3. Recovery/recycling/recharging

equipment

4. Vacuum pump

5. Manifold gauge set

6. Refrigerant ...

Other materials:

Wiring diagram

NISSAN DYNAMIC CONTROL SYSTEM

Wiring Diagram

For connector terminal arrangements, harness layouts, and alphabets in a

(option abbreviation; if not

described in wiring diagram), refer to GI-12, "Connector Information/Explanation

of Option Abbreviation".

...

P1865 gear ratio signal

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always turn

ignition switch OFF and

wait at least 10 seconds before conducting the next test.

>> GO TO 2.

2.DTC REPRODUCTION PROCEDURE

With ...

Ambient sensor

Removal and Installation

REMOVAL

1. Remove bumper fascia assembly. Refer to EXT-13, "Removal and

Installation".

2. Disengage fixing pawl, and then remove ambient sensor (1)

from air guide RH.

: Pawl

3. Disconnect ambient sensor connector (2), and then remove

ambient sensor.

INS ...