Nissan Juke Service and Repair Manual : Center console assembly

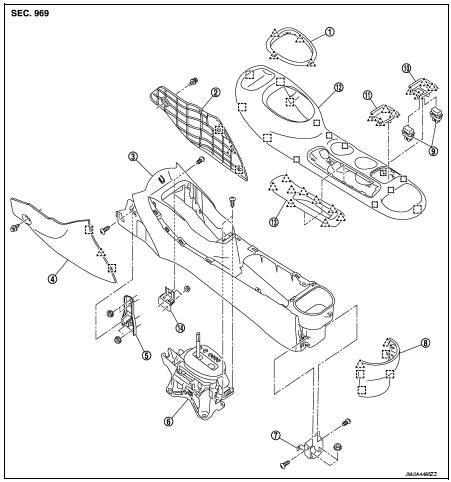

Exploded View

CVT models

1. Console indicator finisher

2. Instrument lower cover RH

3. Center console assembly

4. Instrument lower cover LH

5. Instrument stay

6. CVT shift selector assembly

7. Console rear bracket

8. Console rear finisher

9. Seat heated switch

10. Console switch finisher

11. Console switch finisher

12. Console finisher assembly

13. Console mask

14. Console front bracket

: Pawl

: Pawl

: Metal clip

: Metal clip

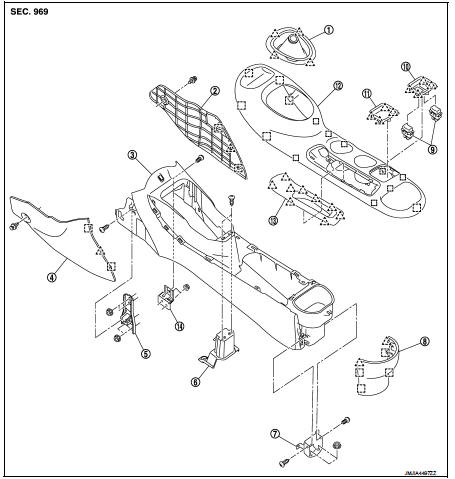

MT model

1. Console boot

2. Instrument lower cover RH

3. Center console assembly

4. Instrument lower cover LH

5. Instrument stay

6. Console center bracket

7. Console rear bracket

8. Console rear finisher

9. Seat heated switch

10. Console switch finisher

11. Console switch finisher

12. Console finisher assembly

13. Console mask

14. Console front bracket

: Pawl

: Pawl

: Metal clip

: Metal clip

Removal and Installation

WARNING:

Before servicing, turn ignition switch OFF, disconnect battery negative terminal

and wait 3 minutes or

more.

REMOVAL

CAUTION:

When removing, always use a remover tool that is made of plastic.

1. Remove shift lever knob (MT models only).

• 5MT models: Refer to TM-25, "Removal and Installation".

• 6MT models: Refer to TM-78, "Removal and Installation".

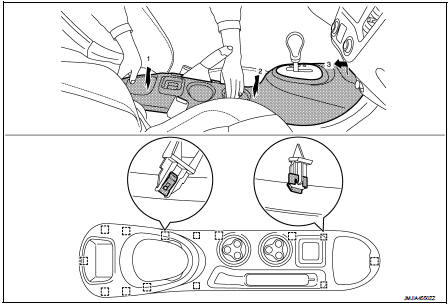

2. Remove console finisher assembly.

1. Put selector lever in “N” position.

2. Loosen the parking brake lever stroke by turning the adjusting nut with a socket wrench. Refer to PB- 2, "Inspection and Adjustment".

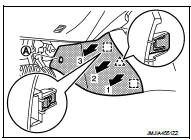

3. Lift up console finisher assembly in numerical order shown in the figure and disengage metal clips.

4. Remove console finisher assembly while pulling it towards vehicle rear.

: Metal clip

: Metal clip

CAUTION:

• Be careful not for damaging parts in surrounding area.

• Remove metal clips slowly so that they are not damaged.

3. Remove console rear finisher.

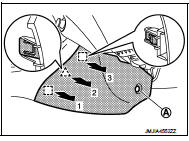

1. Put front seat assembly (LH and RH) to frontmost position.

2. Pull back console rear finisher, and disengage the pawls and metal clips.

: Pawl

: Pawl

: Metal clip

: Metal clip

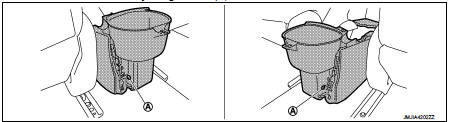

4. Remove center console assembly fixing screws (A).

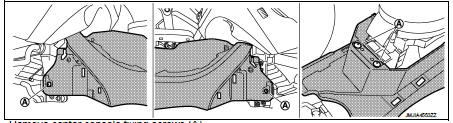

5. Remove instrument lower cover LH.

1. Put front seat assembly LH to rearmost position.

2. Remove fixing clip (A).

3. Pull the instrument lower cover LH crosswise, and disengage the pawl and metal clips.

CAUTION:

Remove pawl and metal clips slowly so that they are not

damaged.

: Pawl

: Pawl

: Metal clip

: Metal clip

6. Remove instrument lower cover RH.

1. Put front seat assembly RH to rearmost position.

2. Remove fixing clip (A).

3. Pull the instrument lower cover RH crosswise, and disengage the pawl and metal clips.

CAUTION:

Remove pawl and metal clips slowly so that they are not

damaged.

: Pawl

: Pawl

: Metal clip

: Metal clip

7. Remove center console assembly.

1. Remove center console fixing screws (A).

2. Lift up center console assembly back side.

CAUTION:

Be careful not for damaging parts in surrounding area.

INSTALLATION

Note the following item, and then install in the reverse order of removal.

CAUTION:

After installation, adjust the parking brake lever stroke. Refer to PB-2,

"Inspection and Adjustment".

Disassembly and Assembly

Disassembly and Assembly of Console Finisher Assembly

CAUTION

:

When disassembling, always use a remover tool that is made of plasti

c.

DISASSEMBLY

1. Remove console finisher assembly. Refer to IP-23, "Removal and Installation".

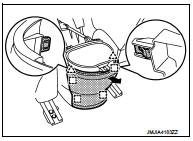

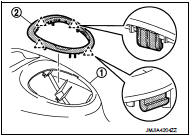

2. Remove console indicator finisher (CVT models)

Disengage connection of the console indicator finisher (2) fixing pawls from the inside of the console finisher assembly (1) toward the outside, and remove.

: Pawl

: Pawl

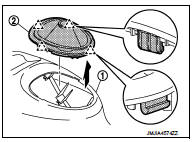

3. Remove console indicator finisher (MT models)

Disengage connection of the console boot (2) fixing pawls from the inside of the console finisher assembly (1) toward the outside, and remove.

: Pawl

: Pawl

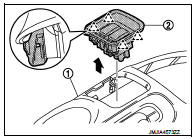

4. Remove console switch finisher.

Disengage connection of the console switch finisher (2) fixing pawls from the inside of the console finisher assembly (1) toward the outside, and remove.

NOTE

:

Remove seat heated switch. Refer to SE-51, "Removal and

Installation".

: Pawl

: Pawl

ASSEMBLY

Assemble in the reverse order of disassembly.

Instrument panel assembly

Instrument panel assembly

Exploded View

LHD models

1. Front passenger air bag module

2. Instrument panel assembly

3. Instrument side finisher LH

4. Combination meter

5. Cluster lid A

6. Push-button ignition switch ...

Seat

Seat

...

Other materials:

Multiport Fuel Injection System or Engine Control System

• Before connecting or disconnecting any harness connector for the

multiport fuel injection system or ECM:

Turn ignition switch to “OFF” position.

Disconnect negative battery terminal. Otherwise, there may be damage to ECM.

• Before disconnecting pressurized fuel line from fuel pump to injecto ...

Power supply and ground circuit

Diagnosis Procedure

1.CHECK GROUND CONNECTION

1. Turn ignition switch OFF.

2. Check ground connection E21 and E38. Refer to Ground Inspection in GI-44,

"Circuit Inspection".

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair or replace ground connection.

...

B1178 lap Pre-tensioner RH

DTC Logic

DTC CONFIRMATION PROCEDURE

1.CHECK SELF-DIAGNOSTIC RESULT

With CONSULT-III

1. Turn ignition switch ON.

2. Perform “Self Diagnostic Result” mode of “AIR BAG” using CONSULT-III.

Without CONSULT-III

1. Turn ignition switch ON.

2. Check the air bag warning lamp status. Refer to SRC ...