Nissan Juke Service and Repair Manual : C1109 power and ground system

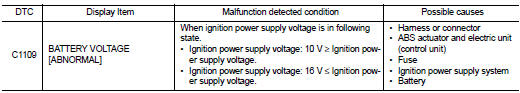

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always turn ignition switch OFF and wait at least 10 seconds before conducting the next test.

>> GO TO 2.

2.CHECK DTC DETECTION

With CONSULT-III.

With CONSULT-III.

1. Turn the ignition switch OFF to ON.

2. Perform self-diagnosis for “ABS” Is DTC “C1109” detected? YES >> Proceed to BRC-45, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Check ABS actuator and electric unit (control unit) harness connector for disconnection or looseness.

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair or replace error-detected parts, securely lock the connector, and GO TO 2.

2.PERFORM SELF-DIAGNOSIS

Perform self-diagnosis for “ABS” again.

Is DTC “C1109” detected? YES >> GO TO 3.

NO >> INSPECTION END

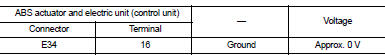

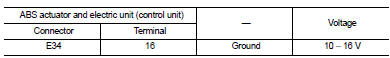

3.CHECK ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT) IGNITION POWER SUPPLY

1. Turn the ignition switch OFF.

2. Disconnect ABS actuator and electric unit (control unit) harness connector.

3. Check voltage between ABS actuator and electric unit (control unit) harness connector and ground.

4. Turn the ignition switch ON.

CAUTION:

Never start engine.

5. Check voltage between ABS actuator and electric unit (control unit) harness connector and ground.

Is the inspection result normal? YES >> GO TO 5.

NO >> GO TO 4.

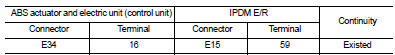

4.CHECK ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT) IGNITION POWER SUPPLY CIRCUIT

1. Turn the ignition switch OFF.

2. Check 10 A fuse (#57).

3. Disconnect IPDM E/R harness connector.

4. Check continuity between ABS actuator and electric unit (control unit) harness connector and IPDM E/R harness connector.

5. Check for continuity between ABS actuator and electric unit (control unit) harness connector and the ground.

Is the inspection result normal? YES >> Perform trouble diagnosis for ignition power supply. Refer to PG-15, "Wiring Diagram - IGNITION POWER SUPPLY -".

NO >> Repair or replace error-detected parts.

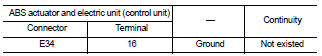

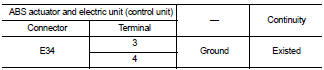

5.CHECK ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT) GROUND CIRCUIT

1. Turn the ignition switch OFF.

2. Check continuity between ABS actuator and electric unit (control unit) harness connector and ground.

Is the inspection result normal? YES >> GO TO 6.

NO >> Repair or replace error-detected parts.

6.CHECK TERMINAL

• Check ABS actuator and electric unit (control unit) pin terminals for damage or loose connection with harness connector.

• Check IPDM E/R pin terminals for damage or loose connection with harness connector.

Is the inspection result normal? YES >> Replace ABS actuator and electric unit (control unit). Refer to BRC-90, "Removal and Installation".

NO >> Repair or replace error-detected parts.

C1105, C1106, C1107, C1108 wheel sensor

C1105, C1106, C1107, C1108 wheel sensor

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always turn

ignition switch OFF and

wait at least 10 ...

C1110 ABS actuator and electric unit (control unit)

C1110 ABS actuator and electric unit (control unit)

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always turn

ignition switch OFF and

wait at least 10 ...

Other materials:

Wiring diagram

MANUAL HEATER SYSTEM

Wiring Diagram

For connector terminal arrangements, harness layouts, and alphabets in a

(option abbreviation; if not

described in wiring diagram), refer to GI-12, "Connector Information/Explanation

of Option Abbreviation".

...

Air cleaner and air duct

Exploded View

1. Mass air flow sensor

2. Gasket

3. Clamp

4. Air duct (suction side)

5. Clamp

6. Air cleaner cover assembly

7. Mounting rubber

8. Air cleaner filter

9. Air cleaner body assembly

10. Air duct with resonator

11. Grommet

12. Air duct (duct side)

13. Grommet

14. B ...

Primary speed sensor

Exploded View

1. Transaxle assembly

2. O-ring

3. Primary speed sensor

: Always replace after every

disassembly.

: N·m (kg-m, in-lb)

: Genuine NISSAN CVT Fluid NS-2

Removal and Installation

REMOVAL

1. Remove the battery. Refer to PG-124, "Removal and Installation".

2. Remove ...