Nissan Juke Service and Repair Manual : Basic inspection

DIAGNOSIS AND REPAIR WORKFLOW

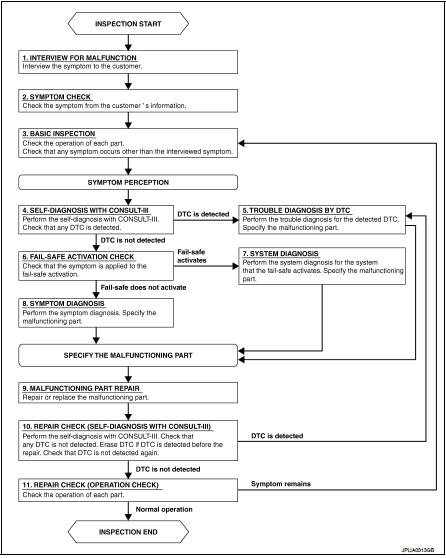

Work Flow

OVERALL SEQUENCE

DETAILED FLOW

1.INTERVIEW FOR MALFUNCTION

Interview the symptom to the customer.

>> GO TO 2.

2.SYMPTOM CHECK

Check the symptom from the customer's information.

>> GO TO 3.

3.BASIC INSPECTION

Check the operation of each part. Check that any symptom occurs other than the interviewed symptom.

>> GO TO 4.

4.SELF-DIAGNOSIS WITH CONSULT-III

Perform the self-diagnosis with CONSULT-III. Check that any DTC is detected.

Is any DTC detected? YES >> GO TO 5.

NO >> GO TO 6.

5.TROUBLE DIAGNOSIS BY DTC

Perform the trouble diagnosis for the detected DTC. Specify the malfunctioning part.

>> GO TO 9.

6.FAIL-SAFE ACTIVATION CHECK

Check that the symptom is applied to the fail-safe activation.

Does the fail-safe activate? YES >> GO TO 7.

NO >> GO TO 8.

7.SYSTEM DIAGNOSIS

Perform the system diagnosis for the system that the fail-safe activates. Specify the malfunctioning part.

>> GO TO 9.

8.SYMPTOM DIAGNOSIS

Perform the symptom diagnosis. Specify the malfunctioning part.

>> GO TO 9.

9.MALFUNCTION PART REPAIR

Repair or replace the malfunctioning part.

>> GO TO 10.

10.REPAIR CHECK (SELF-DIAGNOSIS WITH CONSULT-III)

Perform the self-diagnosis with CONSULT-III. Check that any DTC is not detected. Erase DTC if DTC is detected before the repair. Check that DTC is not detected again.

Is any DTC detected? YES >> GO TO 5.

NO >> GO TO 11.

11.REPAIR CHECK (OPERATION CHECK)

Check the operation of each part.

Does it operate normally? YES >> INSPECTION END

NO >> GO TO 3.

Wiring diagram

Wiring diagram

EXTERIOR LIGHTING SYSTEM

Wiring Diagram

For connector terminal arrangemants, harness layouts, and alphabets in a

(option abbreviation: if not

described in wiring diagram), refer to GI-12, "Co ...

Other materials:

Precaution Necessary for Steering Wheel Rotation after Battery Disconnect

NOTE:

• Before removing and installing any control units, first turn the ignition

switch to the LOCK position, then disconnect

both battery cables.

• After finishing work, confirm that all control unit connectors are connected

properly, then re-connect both

battery cables.

• Always use CONS ...

Center stem assembly

Exploded View

1. Filler plug

2. Gasket

3. Drain plug

4. Breather tube

5. Clip

6. Breather hose

7. Breather

8. sub-harness clip

9. sub-harness

10. Rear cover

11. Center stem

12. Side bearing (right)

13. Side bearing adjusting shim (right)

14. Side oil seal (right)

15. Connec ...

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”,

used along

with a front seat belt, helps to reduce the risk or severity of injury to the

driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage

f ...