Nissan Juke Service and Repair Manual : Basic inspection

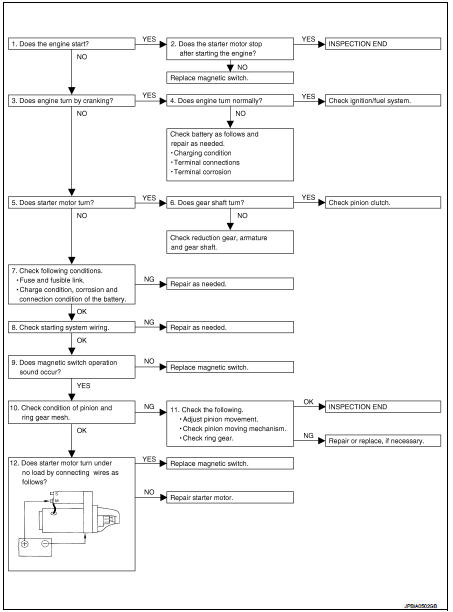

DIAGNOSIS AND REPAIR WORK FLOW

Work Flow

OVERALL SEQUENCE

DETAILED FLOW

NOTE

:

If any malfunction is found, immediately disconnect the battery cable from the

negative terminal.

1.CHECK ENGINE START

Crank the engine and check that the engine starts.

Does the engine start? YES >> GO TO 2.

NO >> GO TO 3.

2.CHECK THAT THE STARTER MOTOR STOPS

Check that the starter motor stops after starting the engine.

Does the starter motor stop? YES >> INSPECTION END

NO >> Replace magnetic switch.

3.CHECK THE ENGINE SPEED WITH CRANKING

Check that the engine runs at cranking.

Does engine turn by cranking? YES >> GO TO 4.

NO >> GO TO 5.

4.CHECK THE ENGINE SPEED WITH CRANKING

Check that the engine speed is not low at cranking.

Does engine turn normally? YES >> Check ignition/fuel system.

NO >> Check charge condition, corrosion and connection condition of the battery. Refer to PG-113, "Work Flow".

5.CHECK STARTER MOTOR ACTIVATION

Check that the starter motor runs at cranking.

Does starter motor turn? YES >> GO TO 6.

NO >> GO TO 7.

6.CHECK STARTER MOTOR UNIT

1. Remove starter motor.

2. Check that the gear shaft of starter motor rotates.

Does gear shaft turn? YES >> Check pinion clutch. Refer to STR-24, "HR16DE : Inspection and Adjustment" (HR16DE) or STR- 30, "MR16DDT : Inspection and Adjustment" (MR16DDT).

NO >> Check reduction gear, armature and gear shaft.

7.CHECK POWER SUPPLY CIRCUIT

Check the following conditions.

• Fuse and fusible link

• Charge condition, corrosion and connection condition of the battery. Refer to PG-113, "Work Flow".

Are these inspection results normal? YES >> GO TO 8.

NO >> Repair as needed.

8.CHECK STARTING SYSTEM WIRING

Check the following.

• “B” terminal circuit. Refer to STR-17, "Diagnosis Procedure".

• “S” terminal circuit. Refer to STR-19, "Diagnosis Procedure".

Are these inspection results normal? YES >> GO TO 9.

NO >> Repair as needed.

9.CHECK MAGNETIC SWITCH OPERATION SOUND

Check that a magnetic switch operation sound can be heard when the ignition switch is set at the starting position.

Does magnetic switch operation sound occur? YES >> GO TO 10.

NO >> Replace magnetic switch.

10.PINION AND RING GEAR ENGAGEMENT CHECK

Check condition of pinion and ring gear mesh.

Is the inspection result normal? YES >> GO TO 12.

NO >> GO TO 11.

11.CHECK STARTER MOTOR UNIT

Check the following.

• Adjust pinion movement. Refer to STR-24, "HR16DE : Inspection and Adjustment" (HR16DE) or STR-30, "MR16DDT : Inspection and Adjustment" (MR16DDT).

• Check pinion moving mechanism.

• Check ring gear.

Are these inspection results normal? YES >> INSPECTION END

NO >> Repair or replace, if necessary.

12.CHECK STARTER MOTOR UNIT

Check that the starter motor runs when connecting the positive terminal (12 V) to starter motor terminal M and the negative terminal (ground) to starter motor body.

Does the starter motor run? YES >> Replace magnetic switch.

NO >> Repair starter motor.

Starting system (without intelligent key)

Starting system (without intelligent key)

CVT : Wiring Diagram

For connector terminal arrangements, harness layouts, and alphabets in a

(option abbreviation; if not

described in wiring diagram), refer to GI-12, "Connector Information/ ...

Other materials:

B1035 crash zone sensor

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.CHECK SELF-DIAG RESULT

With CONSULT-III

1. Turn ignition switch ON.

2. Perform “Self Diagnostic Result” mode of “AIR BAG” using CONSULT-III.

Without CONSULT-III

1. Turn ignition switch ON.

2. Check the air bag warning lamp statu ...

Door does not lock/unlock with door key cylinder operation

Diagnosis Procedure

1.CHECK POWER DOOR LOCK OPERATION

Check power door lock operation.

Does door lock/unlock with door lock and unlock switch?

YES >> GO TO 2.

NO >> Go to DLK-415, "ALL DOOR : Diagnosis Procedure".

2.CHECK UNLOCK SENSOR

Check unlock sensor.

Refer ...

Lift gate

WARNING

• Always be sure the lift gate has been closed securely to prevent it from

opening while driving.

• Do not drive with the lift gate open.

This could allow dangerous exhaust gases to be drawn into the vehicle.

See “Exhaust gas (carbon monoxide)” of this manual.

• Do not leave chi ...