Nissan Juke Service and Repair Manual : B2578, B2579 In-vehicle sensor

DTC Logic

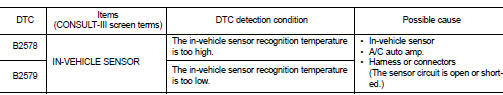

DTC DETECTION LOGIC

NOTE

:

• If DTC is displayed along with DTC U1000, first perform the trouble diagnosis

for DTC U1000. Refer to HAC-

141, "DTC Logic".

• If DTC is displayed along with DTC U1010, first perform the trouble diagnosis for DTC U1010. Refer to HAC- 142, "DTC Logic".

DTC CONFIRMATION PROCEDURE

1.PERFORM DTC CONFIRMATION PROCEDURE

With CONSULT-III

With CONSULT-III

1. Turn ignition switch ON.

2. Select “Self Diagnostic Result” mode of “HVAC” using CONSULT-III.

3. Check DTC.

Is DTC detected? YES >> Refer to HAC-143, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

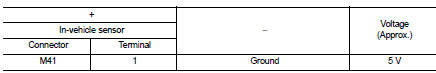

1.CHECK IN-VEHICLE SENSOR POWER SUPPLY

1. Turn ignition switch OFF.

2. Disconnect in-vehicle sensor connector.

3. Turn ignition switch ON.

4. Check voltage between in-vehicle sensor harness connector and ground.

Is the inspection result normal? YES >> GO TO 2.

NO >> GO TO 4.

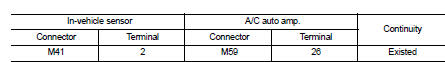

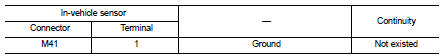

2.CHECK IN-VEHICLE SENSOR GROUND CIRCUIT FOR OPEN

1. Turn ignition switch OFF.

2. Disconnect A/C auto amp. connector.

3. Check continuity between in-vehicle sensor harness connector and A/C auto amp harness connector.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair harness or connector.

3.CHECK IN-VEHICLE SENSOR

Check in-vehicle sensor. Refer to HAC-147, "Component Inspection".

Is the inspection result normal? YES >> Replace A/C auto amp. Refer to HAC-188, "Removal and Installation".

NO >> Replace in-vehicle sensor. Refer to HAC-190, "Removal and Installation".

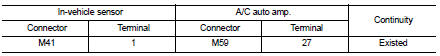

4.CHECK IN-VEHICLE SENSOR POWER SUPPLY CIRCUIT FOR OPEN

1. Turn ignition switch OFF.

2. Disconnect A/C auto amp. connector.

3. Check continuity between in-vehicle sensor harness connector and A/C auto amp. harness connector.

Is the inspection result normal? YES >> GO TO 5.

NO >> Repair harness or connector.

5.CHECK IN-VEHICLE SENSOR POWER SUPPLY CIRCUIT FOR SHORT

Check continuity between in-vehicle sensor harness connector and ground.

Is the inspection result normal? YES >> Replace A/C auto amp. Refer to HAC-188, "Removal and Installation".

NO >> Repair harness or connector.

Component Inspection

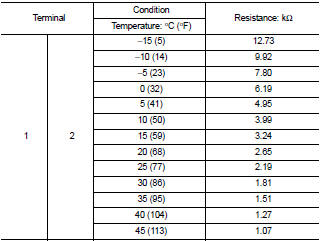

1.CHECK IN-VEHICLE SENSOR

1. Remove in-vehicle sensor. Refer to HAC-190, "Removal and Installation".

2. Check resistance between in-vehicle sensor terminals. Refer to applicable table for the normal value.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace in-vehicle sensor. Refer to HAC-190, "Removal and Installation".

U1010 control unit (can)

U1010 control unit (can)

Description

Initial diagnosis of A/C auto amp.

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PERFORM SELF-DIAGNOSIS

With CONSULT-III

1. Turn ignition switch ON.

2. Select “Self ...

B257B, B257C ambient sensor

B257B, B257C ambient sensor

DTC Logic

DTC DETECTION LOGIC

NOTE:

• If DTC is displayed along with DTC U1000, first perform the trouble diagnosis

for DTC U1000. Refer to HAC-

141, "DTC Logic".

• If DTC is displaye ...

Other materials:

Normal operating condition

Description

FUEL CUT CONTROL (AT NO LOAD AND HIGH ENGINE SPEED)

If the engine speed is above 2,400 rpm under no load (for example, the shift

lever position is neutral and

engine speed is over 2,400 rpm) fuel will be cut off after some time. The exact

time when the fuel is cut off varies

base ...

Lower Anchors and Tethers for CHildren System (LATCH)

LATCH label location

Your vehicle is equipped with special anchor points that are used with LATCH

(Lower Anchors and Tethers for CHildren) system compatible child restraints. This

system may also be referred to as the ISOFIX or ISOFIX compatible system. With this

system, you do not have to ...

Vehicle speed sensing auto lock operation does not operate

Diagnosis Procedure

1.CHECK “AUTOMATIC LOCK/UNLOCK SELECT” SETTING IN “WORK SUPPORT”

1. Select “DOOR LOCK” of “BCM” using CONSULT-III.

2. Select “AUTOMATIC LOCK/UNLOCK SELECT” in “WORK SUPPORT” mode.

3. Check “AUTOMATIC LOCK/UNLOCK SELECT” in “WORK SUPPORT”.

Refer to DLK-41, "DOOR LOCK : ...