Nissan Juke Service and Repair Manual : B210B starter control relay

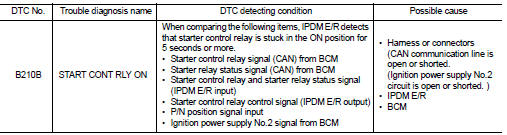

DTC Logic

DTC DETECTION LOGIC

NOTE

:

If DTC B210B is displayed with DTC U1000, first perform the trouble diagnosis

for DTC U1000. Refer to PCS-

30, "DTC Logic".

DTC CONFIRMATION PROCEDURE

1.PERFORM DTC CONFIRMATION PROCEDURE

1. Press push-button ignition switch under the following conditions to start engine, and wait 5 seconds or more.

- Selector lever: In the P position - Brake pedal: Depressed 2. Check DTC in “Self Diagnostic Result” mode of “IPDM E/R” using CONSULT-III.

Is DTC detected? YES >> Go to SEC-142, "Diagnosis Procedure".

NO >> GO TO 2.

2.PERFORM DTC CONFIRMATION PROCEDURE 2

1. Stop engine.

2. Perform DTC CONFIRMATION PROCEDURE for DTC P1650. Refer to EC-366, "DTC Logic" (MR16DDT) or EC-725, "DTC Logic" (HR16DE).

3. Turn ignition switch ON.

4. Check DTC in “Self Diagnostic Result” mode of “IPDM E/R” using CONSULT-III.

Is DTC detected? YES >> Refer to SEC-142, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

1.INSPECTION START

Perform inspection in accordance with procedure that confirms DTC.

Which procedure confirms DTC? DTC confirmation procedure 1>>GO TO 2.

DTC confirmation procedure 2>>GO TO 4.

2.CHECK DTC OF BCM

Check DTC in “Self Diagnostic Result” mode of “BCM” using CONSULT-III.

Is DTC detected? YES >> Perform the trouble diagnosis related to the detected DTC. Refer to BCS-67, "DTC Index".

NO >> GO TO 3.

3.INSPECTION STAR

1. Turn ignition switch ON.

2. Select “Self Diagnostic Result” mode of “IPDM E/R” using CONSULT-III.

3. Touch “ERASE”.

4. Perform DTC CONFIRMATION PROCEDURE for DTC B210B. Refer to SEC-142, "DTC Logic".

Is DTC detected? YES >> GO TO 6.

NO >> INSPECTION END

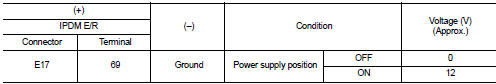

4.CHECK IGNITION POWER SUPLLY NO.2 SIGNAL

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R connector.

3. Check voltage between IPDM E/R harness connector and ground.

Is the inspection result normal? YES >> Replace IPDM E/R. Refer to PCS-34, "Removal and Installation".

NO >> GO TO 5.

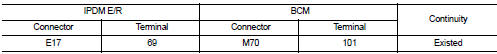

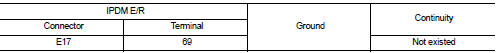

5.CHECK BCM INPUT SIGNAL CIRCUIT

1. Disconnect BCM connector.

2. Check continuity between IPDM E/R harness connector and BCM harness connector.

3. Check continuity between transmission range switch harness connector and ground.

Is the inspection result normal? YES >> GO TO 6.

NO >> Repair or replace harness.

6.REPLACE BCM

1. Replace BCM. Refer to BCS-93, "Removal and Installation".

2. Perform initialization of BCM and registration of all Intelligent Keys using CONSULT-III.

For initialization and registration procedures, refer to CONSULT-III Operation Manual NATS-IVIS/NVIS.

3. Perform DTC CONFIRMATION PROCEDURE for DTC B210B. Refer to SEC-142, "DTC Logic".

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace IPDM E/R. Refer to PCS-34, "Removal and Installation".

B210A steering lock unit

B210A steering lock unit

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PERFORM DTC CONFIRMATION PROCEDURE 1

1. Press push-button ignition switch under the following conditions and wait

1 second or more.

...

B210C starter control relay

B210C starter control relay

DTC Logic

DTC DETECTION LOGIC

NOTE:

• If DTC B210C is displayed with DTC U1000, first perform the trouble diagnosis

for DTC U1000. Refer to

PCS-30, "DTC Logic".

• When IPDM E/R power ...

Other materials:

Diagnosis and repair workflow

Work F

OVERALL SEQUENCE

DETAILED FLOW

1.GET INFORMATION FOR SYMPTOM

Get the detailed information from the customer about the symptom (the

condition and the environment when

the incident/malfunction occurred) using the “Diagnostic Work Sheet”. (Refer to

EC-127, "Diagnostic Work

Sheet ...

The parking brake release warning continues sounding, or

does not sound

Description

• The parking brake warning buzzer sounds continuously during vehicle travel

though the parking brake is

released.

• The parking brake warning buzzer does not sound at all even though driving the

vehicle with the parking

brake applied.

Diagnosis Procedure

1.CHECK PARKING BRAKE ...

Intelligent Key battery discharge

If the battery of the Intelligent Key is discharged, or environmental conditions

interfere with the Intelligent Key operation, start the engine according to the

following procedure:

1. Move the shift lever to the P (Park) position (for Continuously Variable Transmission

models) or the shift ...