Nissan Juke Service and Repair Manual : B2099 ignition relay off stuck

Description

The ignition relay integrated in IPDM E/R is operated with ignition switch ON signal from the ignition switch.

DTC Logic

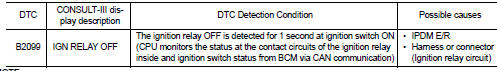

DTC DETECTION LOGIC

NOTE

:

When IPDM E/R power supply voltage is low (Approx. 7 - 8 V for about 1 second),

the “DTC: B2099” may be detected.

1.PERFORM DTC CONFIRMATION PROCEDURE

1. Turn ignition switch ON.

2. Check DTC in “Self Diagnostic Result” mode of “IPDM E/R” using CONSULT-III.

Is DTC detected? YES >> Refer to PCS-61, "Diagnosis Procedure".

NO >> INSPECTION END.

Diagnosis Procedure

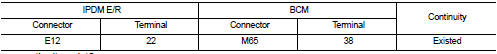

1.CHECK IGNITION SWITCH ON SIGNAL CIRCUIT

1. Turn the ignition switch OFF.

2. Disconnect IPDM E/R harness connector and BCM harness connector.

3. Check continuity between IPDM E/R harness connectors and BCM harness connectors.

Does continuity exist? YES >> Replace IPDM E/R. Refer to PCS-63, "Removal and Installation".

NO >> Repair the harness or connector.

B2098 ignition relay on stuck

B2098 ignition relay on stuck

Description

The ignition relay integrated in IPDM E/R is operated with ignition switch ON

signal from the ignition switch.

DTC Logic

DTC DETECTION LOGIC

1.PERFORM DTC CONFIRMATION PROCEDURE

1 ...

Power supply and ground circuit

Power supply and ground circuit

Diagnosis Procedure

1.CHECK FUSES AND FUSIBLE LINK

Check that the following IPDM E/R fuses or fusible links are not blown.

Is the fuse fusing?

YES >> Replace the blown fuse or fusible link ...

Other materials:

P061A ECM

DTC Logic

DTC DETECTION LOGIC

Diagnosis Procedure

1.INSPECTION START

1. Turn ignition switch ON.

2. Erase DTC.

3. Turn ignition switch OFF and wait for 20 seconds.

4. Turn ignition switch ON and perform the self-diagnosis.

Is the DTC P061A displayed again?

YES >> GO TO 2.

NO &g ...

Inspection

OIL LEAKAGE

Check transfer surrounding area (oil seal, drain plug, filler plug, and

transfer case etc.) for oil leakage.

OIL LEVEL

1. Remove filler plug (1) and gasket. Then check that oil is filled up

from mounting hole for the filler plug.

Vehicle front

CAUTION:

Never start engine while ...

Oil pan (upper)

Exploded View

With Oil Cooler

1. Rear oil seal

2. O-ring

3. Oil pan (upper)

4. Oil pump chain tensioner (for oil

pump drive chain)

5. Oil pump drive chain

6. Crankshaft sprocket

7. Oil pump sprocket

8. Oil pump

9. O-ring

10. O-ring

11. Oil pan (lower)

12. Oil pan drain plug

1 ...