Nissan Juke Service and Repair Manual : Air cleaner and air duct

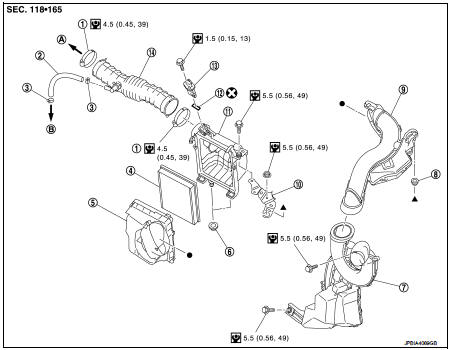

Exploded View

1. Hose clamp

2. PCV hose

3. Hose clamp

4. Air cleaner filter

5. Air cleaner filter case

6. Grommet

7. Inlet air duct (lower)

8. Grommet

9. Inlet air duct (upper)

10. Bracket

11. Air cleaner case

12. O-ring

13. Mass air flow sensor

14. Air duct

A. To electric throttle control actuator B. To rocker cover

: Always replace after every

: Always replace after every

disassembly.

: N·m (kg-m, in-lb)

: N·m (kg-m, in-lb)

Removal and Installation

REMOVAL

NOTE

:

Mass air flow sensor is removable under the car-mounted condition.

1. Remove the clip of front fender protector (left) to lift the front fender protector.

2. Remove the front side glille (left) from front bumper.

3. Remove installing bolts from inlet air duct (lower).

4. Disconnect mass air flow sensor harness connector.

5. Loosen the hose clamp of air duct.

6. Remove installing bolts from air cleaner case.

7. Remove inlet air duct (upper) and air cleaner simultaneously 8. Remove inlet air duct (lower) 9. .Disconnect PCV hose.

10. Remove air duct.

11. Remove mass air flow sensor from air cleaner case, if necessary.

CAUTION:

Handle the mass air flow sensor with following cares.

• Never shock the mass air flow sensor.

• Never disassemble the mass air flow sensor.

• Never touch the sensor of the mass air flow sensor.

INSTALLATION

Note the following, and install in the reverse order of removal.

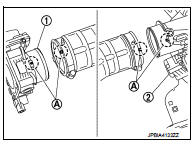

• To install air duct, align the matching marks on both ends with the others.

1. : Electric throttle control actuator

2. : Air cleaner case

A. : Matching mark

• Align marks. Attach each joint. Screw clamps firmly.

Clamp tightening torque : 4.5 N·m (0.46 kg-m)

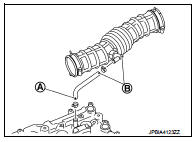

• Install PVC hose with each matching mark positioned as follows:

A : White mark

B : Matching mark

Air duct side : Align the matching mark with that of air duct side.

Rocker cover side : Face the white mark in forward direction of the vehicle.

Inspection

INSPECTION AFTER REMOVAL

Inspect air duct for crack or tear.

• If anything found, replace air duct.

Drive belt idler pulley

Drive belt idler pulley

Removal and Installation

REMOVAL

1. Remove drive belt. Refer to EM-155, "Removal and Installation".

2. Remove the lock nut, and then remove the plate (7), idler pulley

(6), and washer (5 ...

Intake manifold

Intake manifold

Exploded View

1. EVAP canister purge volume control

solenoid valve

2. Hose clamp

3. Vacuum hose

4. Intake manifold support

5. Gasket

6. Intake manifold

7. Electric throttle control actua ...

Other materials:

P012B TC boost sensor

DTC Logic

DTC DETECTION LOGIC

Diagnosis Procedure

1.CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Check ground connection E38. Refer to Ground inspection in GI-44, "Circuit

Inspection".

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair or ...

Hood switch

Component Function Check

1.CHECK FUNCTION

1. Select “HOOD SW” in “Data Monitor” mode of “IPDM E/R” using CONSULT-III.

2. Check “HOOD SW” indication under the following condition.

Is the indication normal?

YES >> Hood switch is OK.

NO >> Go to SEC-155, "Diagnosis Procedure& ...

Inspection

LEVEL

• Check that the reservoir tank engine coolant level is within the

“MIN” to “MAX” when the engine is cool.

A : MAX

B : MIN

• Adjust the engine coolant level if necessary.

LEAKAGE

• To check for leakage, apply pressure to the cooling system with the

radiator cap tester (commercial ser ...