Nissan Juke Service and Repair Manual : Structure and operation

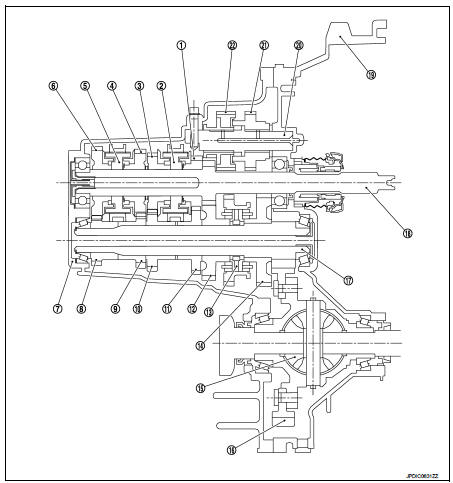

Sectional View

1. 3rd input gear

2. 3rd-4th synchronizer hub assembly

3. 4th input gear

4. 5th input gear

5. 5th-6th synchronizer hub assembly

6. 6th input gear

7. Transaxle case

8. 6th main gear

9. 5th main gear

10. 4th main gear

11. 3rd main gear

12. 2nd main gear

13. 1st-2nd synchronizer hub assembly

14. 1st main gear

15. Differential

16. Final gear

17. Mainshaft

18. Input shaft

19. Clutch housing

20. Reverse idler shaft

21. Reverse input gear

22. Reverse output gear

System Description

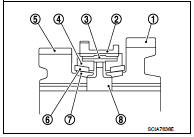

TRIPLE-CONE SYNCHRONIZER

Triple-cone synchronizers are adopted for the 1st and the 2nd gears to reduce operating force of the shifter lever.

1 : 1st main gear

2 : 1st-2nd coupling sleeve

3 : Insert key

4 : Outer baulk ring

5 : 2nd main gear

6 : Synchronizer cone

7 : Inner baulk ring

8 : 1st-2nd synchronizer hub

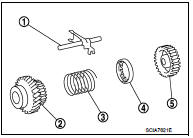

REVERSE GEAR NOISE PREVENTION FUNCTION (SYNCHRONIZING METHOD)

Reverse gear assembly consists of reverse input gear, return spring, reverse baulk ring, and reverse output gear. When the shifter lever is shifted to the reverse position, the construction allows smooth shift operation by stopping the reverse idler shaft rotation by frictional force of synchronizer.

1 : Reverse fork rod

2 : Reverse output gear

3 : Return spring

4 : Reverse baulk ring

5 : Reverse input gear

Component parts

Component parts

Component Parts Location

POSITION SWITCH

1 : Position switch

...

DTC/Circuit diagnosis

DTC/Circuit diagnosis

POSITION SWITCH ...

Other materials:

Precaution

Precautions for Trouble Diagnosis

CAUTION:

• Never apply 7.0 V or more to the measurement terminal.

• Use a tester with open terminal voltage of 7.0 V or less.

• Turn the ignition switch OFF and disconnect the battery cable from the

negative terminal when

checking the harness.

Precautions fo ...

S mode switch

Component Function Check

1.CHECK S MODE INDICATOR FUNCTION

Check S mode indicator turns ON for approx. 2 seconds when ignition switch

turns ON.

Is the inspection results normal?

YES >> GO TO 2.

NO >> Go to TM-469, "Diagnosis Procedure".

2.CHECK S MODE SWITCH FUNCT ...

A/C switch

Component Function Check

1.CHECK A/C ON SIGNAL

With CONSULT-III

1. Turn ignition switch ON.

2. Select “AIR CONDITIONER” of “BCM” using CONSULT-III.

3. Select “AIR COND SW” in “DATA MONITOR” mode, and check status under the

following condition.

Is the inspection result normal?

YES >> ...